An economical non-quenched and tempered micro-alloyed plastic mold steel plate and its manufacturing method

A plastic mold and microalloying technology, which is applied in the field of economical non-quenched and tempered microalloyed plastic mold steel plate and its manufacturing, can solve the problems of uneven microstructure and section hardness, high alloy cost and manufacturing cost, and reduce component segregation , reduce the cost of the alloy, and improve the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

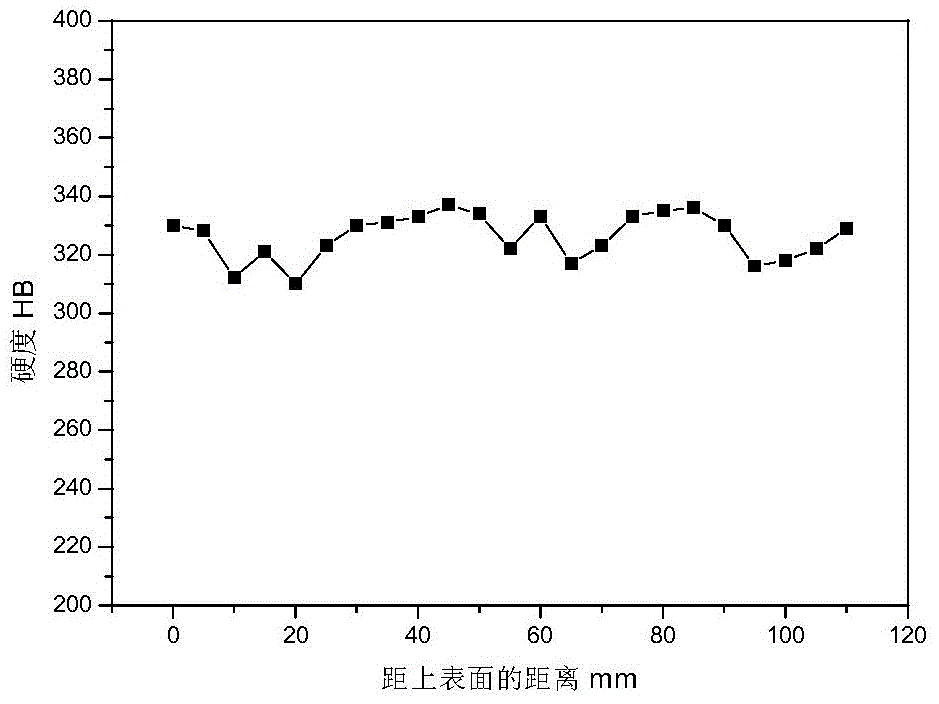

[0029] An economical method for manufacturing non-quenched and tempered micro-alloyed plastic mold steel plates, using converter smelting, LF+RH refining and pouring continuous casting slabs, the heating temperature of the slabs for pouring continuous casting slabs is 1200-1230°C, and the steel plates are subjected to controlled rolling The finish rolling temperature is 900-950°C, the final rolling temperature is 870-920°C, the steel plate is cooled after rolling, and tempered at 550-600°C after rolling; after tempering, the yield strength of the finished steel plate of plastic mold steel reaches 800 MPa or more , the section hardness is 310-340 HB, which meets the performance requirements of P20 pre-hardened steel plate. The specific steps and requirements are as follows:

[0030]1) Converter smelting, LF+RH refining, and continuous casting to obtain continuous casting slabs; the chemical composition of continuous casting slabs meets carbon: 0.32-0.40%, silicon: 0.20-0.50%, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com