Method for producing medium ferrovanadium by ferrovanadate ferroelectric silicothermal method

An electro-silicothermal method and iron vanadate technology, which is applied in the field of ferrovanadium production to achieve the effects of optimizing the structure of vanadium products, promoting development and innovation, and achieving remarkable environmental protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

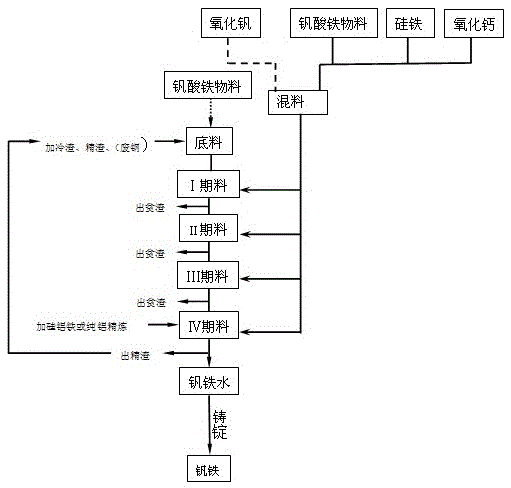

[0036] Embodiment 1: The processing steps of the method for producing medium ferrovanadium by ferrovanadate ferroelectric silicothermal method are as follows.

[0037]The composition of ferric vanadate in the raw material is 33% iron, 29% vanadium, and 37% oxygen. Ferrosilicon (75% ferrosilicon) needs to be added during reduction, which is 0.49% of the mass of iron vanadate. According to calculation, the vanadium content of ferrovanadium is 39%, the production of FeV50 that meets the national standard needs to add vanadium oxide, the added vanadium pentoxide is 0.195 of iron vanadate, and the added pure aluminum for reduction of added vanadium pentoxide is 0.1 of iron vanadate, because Fe Excessive, no need to add additional scrap. Ferric vanadate, ferrosilicon, vanadium oxide, and calcium oxide are prepared according to the calculated proportions, and then they are divided into four phases and added to the electric silicon heating furnace for smelting. Refining, guarantee th...

Embodiment 2

[0038] Embodiment 2: The processing steps of the method for producing medium ferrovanadium by ferrovanadate ferroelectric silicothermal method are as follows.

[0039] The composition of ferric vanadate in the raw material is 23% iron, 37% vanadium, and 39% oxygen. Ferrosilicon needs to be added during reduction to be 0.52 of the mass of ferric vanadate. When producing FeV50 that meets the national standard, Fe, The V ratio contains 50.6% vanadium, which meets the requirements of the national standard FeV50. Ferric vanadate, ferrosilicon, and calcium oxide can be directly mixed according to the calculated ratio, and then added into the electric silicon heating furnace for smelting in four stages. After adding the furnace materials in the stage IV for smelting, add silicon-aluminum iron or pure aluminum for refining, and ensure the alkalinity in the furnace during the smelting process (CaO%:SiO 2 %) In 2.1, after obtaining the qualified molten vanadium iron, the fine slag is di...

Embodiment 3

[0040] Embodiment 3: The process steps of the method for producing medium ferrovanadium by ferrovanadate ferroelectric silicothermal method are as follows.

[0041] The composition of ferric vanadate in the raw material is 16% iron, 43.3% vanadium, and 39% oxygen. Ferrosilicon needs to be added during reduction, which is 0.52% of the mass of ferric vanadate. When producing medium ferrovanadium containing 50% vanadium, add If Fe is less than 50% of the ferrovanadium iron content, scrap steel needs to be added, and the added scrap steel is 0.15 of ferric vanadate. Because V is too much, no additional vanadium oxide is needed. After the ferric vanadate, ferrosilicon and calcium oxide are prepared according to the calculated ratio, they are divided into four phases and added to the electric silicon heating furnace for smelting. Guarantee the basicity in the furnace during the process (CaO%:SiO 2 %) at 2.5, after obtaining qualified molten vanadium iron, the fine slag is discharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com