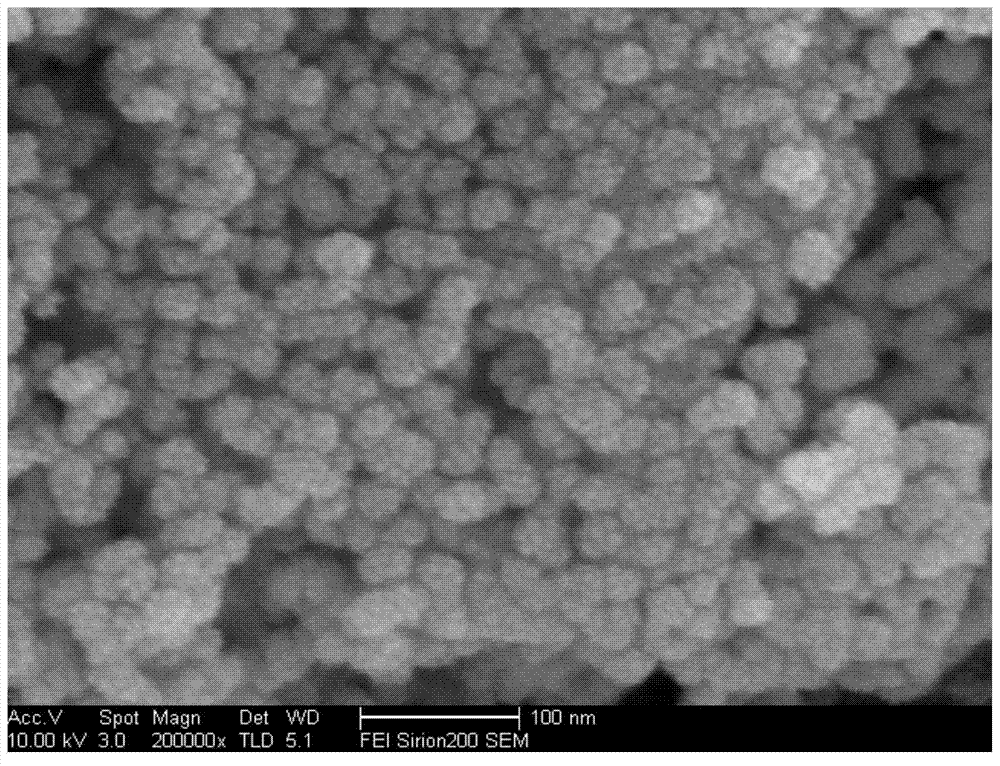

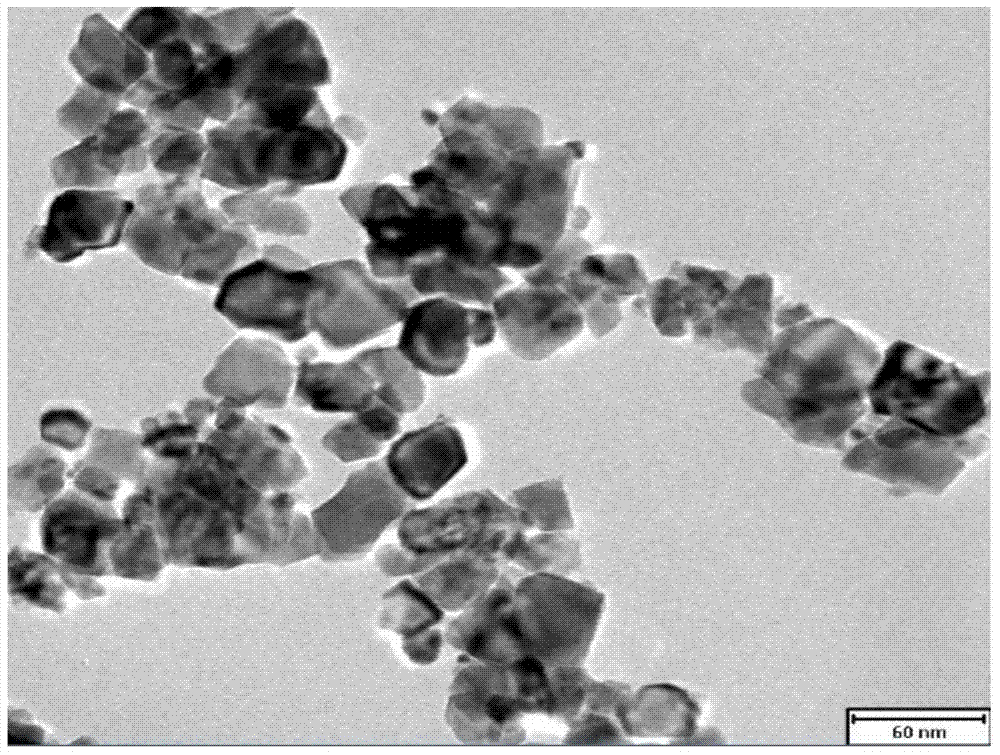

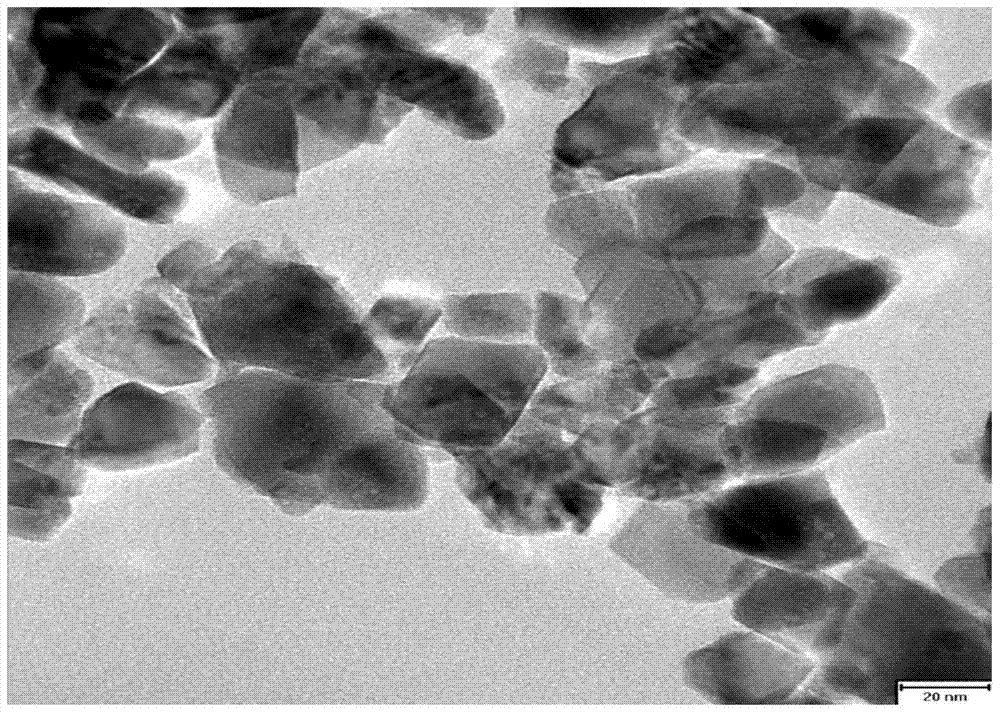

Zirconia composite nano-powder material and preparation method thereof

A technology of nano-powder and zirconia, which is applied in chemical instruments and methods, catalyst carriers, conductive coatings, etc., can solve the problems that it is difficult to prepare high-performance nano-zirconia-titania coatings, good dispersion, etc., and achieve the elimination of hardness The effect of agglomeration, high activity and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Prepare the zirconia composite nanopowder material of the present invention according to the following steps

[0068] ①. Solution A is zirconium oxychloride ZrOCl 2 .8H 2 Preparation of O absolute ethanol solution

[0069] First preparation concentration is 2000 milliliters of dehydrated ethanol solutions of zirconium oxychloride of 0.5mol / L, then in prepared solution, adding molecular weight is 12 grams of polyethylene glycols of 2000, stirs;

[0070] ②. Solution B is the preparation of absolute ethanol solution of butyl titanate

[0071] First prepare 2325 milliliters of absolute ethanol solution of butyl titanate with a concentration of 0.3 mol / L, then add 13 grams of triethanolamine to the prepared solution, and stir evenly;

[0072] ③. Prepare the aqueous ammonium bicarbonate solution whose molar concentration is 2.0mol / L;

[0073] ④. Preparation of mixed sol

[0074] First, under stirring conditions, the solution A prepared in step 1 and the solution B prepar...

Embodiment 2

[0081] According to the method and step of embodiment 1, concrete formula, processing condition are as follows:

[0082] Prepare 2000ml of 1.5mol / L zirconium oxychloride absolute ethanol solution, add 21g polyethylene glycol, and stir evenly; prepare 1265ml0.5mol / L butyl titanate solution with absolute ethanol as solvent, and add 11g of triethanolamine, stirred evenly; prepare an aqueous ammonium bicarbonate solution with a molar concentration of 1.0mol / L; mix the prepared a and b solutions under stirring conditions, and spray the ammonium bicarbonate aqueous solution to the The mixed solution of a and b in the stirring state, the reaction temperature is 70°C, spray until the final pH value is 7-8, stop adding, continue to stir for 7 hours, age for 15 hours, filter and wash; the dehydration and drying process uses isobutanol as the azeotrope agent, the azeotropic point is 89.9°C, after dehydration is completed, the temperature of the system rises to the boiling point of isobut...

Embodiment 3

[0086] According to the method and step of embodiment 1, concrete formula, processing condition are as follows:

[0087] Prepare 2000ml of 1.0mol / L zirconium oxychloride absolute ethanol solution, add 35g polyethylene glycol, and stir evenly; prepare 1350ml0.8mol / L butyl titanate solution with absolute ethanol as solvent, and add 8g of triethanolamine, stirred evenly; prepare an aqueous ammonium bicarbonate solution with a molar concentration of 3.0mol / L, the reaction temperature is 40°C, mix the prepared a and b solutions under stirring conditions, and pass the aqueous ammonium bicarbonate solution through After spraying and atomizing, spray to the mixed solution of a and b in the stirring state, the reaction temperature is 60°C, spray until the final pH value is 7-8, stop adding, continue stirring for 8 hours, age for 13 hours, filter and wash; the dehydration and drying process uses N-butanol is the entrainer, and the azeotropic point is 93°C. After dehydration, the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com