Efficient cementitious capillary crystalline waterproofing coating as well as preparation method and construction method thereof

A technology of osmotic crystalline waterproofing and osmotic crystalline masterbatch, which is applied in the field of waterproof coatings and construction engineering waterproof coatings. strong knot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

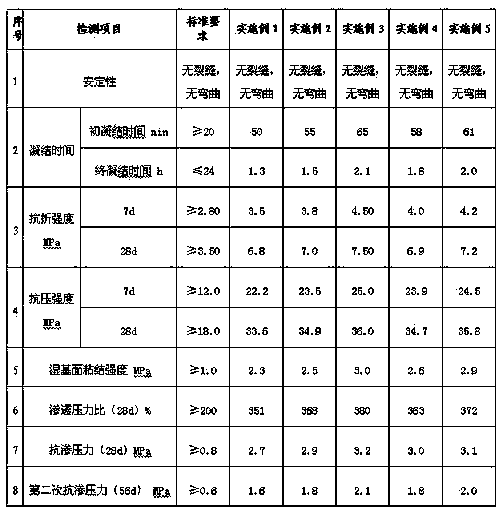

Examples

Embodiment 1

[0030] Example 1, a high-efficiency cement-based penetrating crystalline waterproof coating, including the following raw materials in parts by weight: 40% Portland cement, 12% high-activity masterbatch, 20% quartz sand, 0.3% catalyst, 1.2% diffusing agent .

[0031] The Portland cement is P.042.5 ordinary Portland cement; the high activity masterbatch is CRM-1 cement-based permeable crystallization masterbatch; the catalyst is methyl cellulose ether with a molecular weight of 60,000-80,000; the quartz sand is 100 Purpose Quartz sand; the diffusing agent is lithium magnesium silicate.

Embodiment 2

[0032] Example 2, a high-efficiency cement-based osmotic crystalline waterproof coating, a high-efficiency cement-based osmotic crystalline waterproof coating, including the following raw materials in parts by weight: 70% Portland cement, 23% high-activity masterbatch, 30% Quartz sand, 1.2% catalyst, 3% diffusing agent.

[0033] The Portland cement is P.042.5 ordinary Portland cement; the high activity masterbatch is CRM-1 cement-based permeable crystallization masterbatch; the catalyst is methyl cellulose ether with a molecular weight of 60,000-80,000; the quartz sand is 100 Purpose Quartz sand; the diffusing agent is lithium magnesium silicate.

Embodiment 3

[0034] Example 3, a high-efficiency cement-based permeable crystalline waterproof coating, including the following raw materials in parts by weight: 55% Portland cement, 17% high-activity masterbatch, 25% quartz sand, 1% catalyst, 2% diffusing agent .

[0035] The Portland cement is P.042.5 ordinary Portland cement; the high activity masterbatch is CRM-1 cement-based permeable crystallization masterbatch; the catalyst is methyl cellulose ether with a molecular weight of 60,000-80,000; the quartz sand is 100 The purpose is quartz sand; the diffusing agent is triethanolamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com