A method for preparing high-quality iron oxide powder using hydrochloric acid pickling waste liquid

A technology of pickling waste liquid and iron oxide powder, which is applied in the field of metallurgy, can solve the problems of unsatisfactory preparation of high-quality iron oxide powder, achieve significant promotion value, reduce time, and increase production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

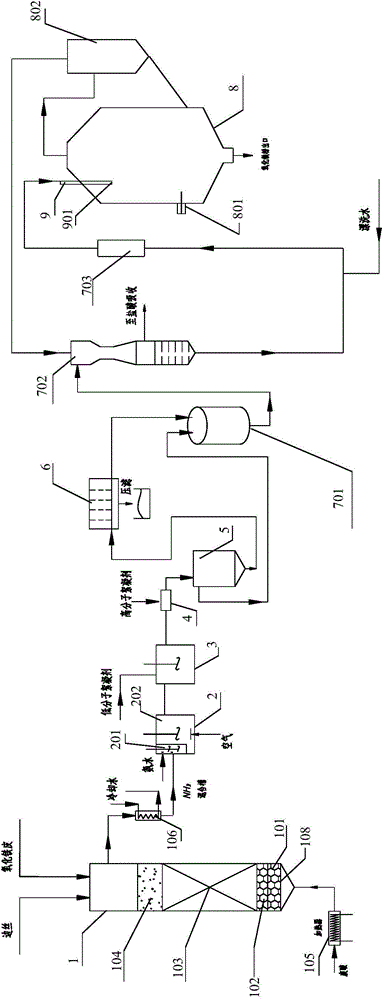

[0031] A certain acid regeneration unit has applied the technology of the present invention, and its equipment structure is as follows figure 2 As shown, it includes a waste acid dissolution tower 1, a reaction tank 2, a flocculation reaction tank 3, a pipeline mixer 4, a settling tank 5, a filter press, a collection tank 701, a concentrator 702 and a spray roaster 8 connected in sequence.

[0032] Place silicon nitride ceramic balls I 101 and silicon nitride ceramic balls II 102 with diameters 1.2 to 2 times and 0.8 to 1.0 times the opening diameter of the bottom partition in sequence on the bottom partition of the waste acid dissolution tower; the inlet of waste acid Located at the bottom of the waste acid dissolution tower, the top of the waste acid dissolution tower is connected to the cooler 106, reaction tank 2, flocculation reaction tank 3, pipeline mixer 4, and settling tank 5 in sequence; the upper part of the settling tank is connected to the collection tank 701, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com