Sodium dichromate closed circulation clean production method for preparing sodium chlorate

A sodium dichromate and closed-circuit cycle technology, applied in the direction of chloric acid and chlorate, can solve the problems of increasing air pollution, deteriorating the atmospheric environment, and human injury, achieving low production costs, increasing benefits, and eliminating chromium salt mud the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

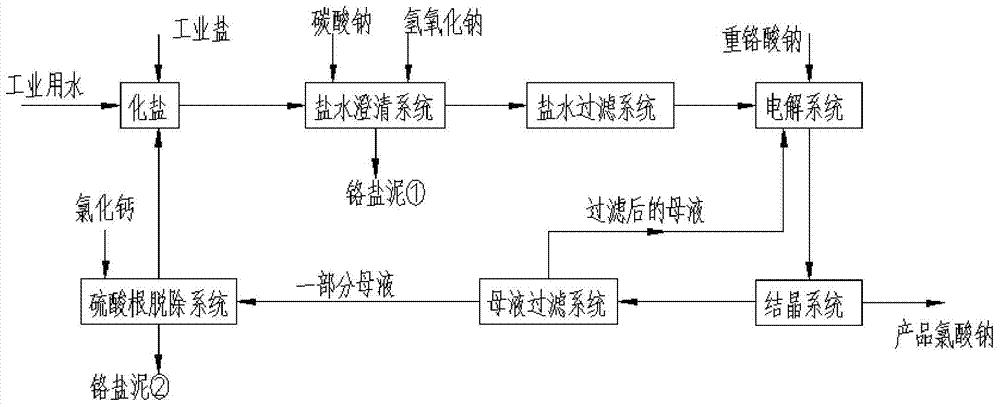

[0041] combined with figure 2 Shown, the concrete steps of preparing sodium chlorate are:

[0042] Use industrial water to dissolve industrial salt to prepare saturated brine;

[0043] Add sodium carbonate and sodium hydroxide at one time and stir to react with calcium and magnesium ions in the brine to form barium carbonate precipitates and magnesium hydroxide colloidal substances. The volume ratio of sodium oxide mass to brine is 0.5g / L. After settling, supernatant brine 1 enters a tubular ceramic membrane filtration system with a pore size of 50nm. The filtration method is cross-flow filtration to obtain first-grade refined brine;

[0044] The primary refined brine was adjusted to pH 2 with concentrated hydrochloric acid, and then barium chloride was metered in at one time, so that the SO in the brine 4 2- Concentration of 0.5mg / L, Ba in brine 2+ The control amount is 93mg / L. After settling, the precipitate barium sulfate plate and frame filter press is carefully press...

Embodiment 2

[0048] Collect the saline wastewater in the factory (without organic matter, S, P, N, etc.) and other reusable wastewater for desalination to form saturated crude brine, and the supernatant of the crude brine overflows to the brine and refining system;

[0049] Add sodium carbonate and sodium hydroxide at one time and stir to react with calcium and magnesium ions in the brine to form barium carbonate precipitates and magnesium hydroxide colloidal substances. The volume ratio of sodium oxide mass to brine is 0.5g / L. After settling for 0.5h, supernatant brine 1 enters a tubular ceramic membrane filtration system with a pore size of 50nm (the filtration method is cross-flow filtration) to obtain first-grade refined brine;

[0050] Obtain the first grade refined brine, the content of each component in the brine is: NaCl>300g / L, Ca 2+ +Mg 2+ 4 2- Between 0.5 ~ 1.5g / L, without water insoluble matter;

[0051] The primary refined brine was adjusted to pH 3 with concentrated hydroc...

Embodiment 3

[0054] Collect the saline wastewater in the factory (without organic matter, S, P, N, etc.) and other reusable wastewater for desalination to form saturated crude brine, and the supernatant of the crude brine overflows to the brine and refining system;

[0055] Add sodium carbonate and sodium hydroxide at one time and stir to react with calcium and magnesium ions in the brine to form barium carbonate precipitates and magnesium hydroxide colloidal substances. The volume ratio of sodium oxide mass to brine is 0.5g / L. After settling for 1 hour, supernatant brine 1 enters a tubular ceramic membrane filtration system with a pore size of 50nm (the filtration method is cross-flow filtration) to obtain first-grade refined brine;

[0056] Obtain the first grade refined brine, the content of each component in the brine is: NaCl>300g / L, Ca 2+ +Mg 2+ 4 2- Between 0.5 ~ 1.5g / L, without water insoluble matter;

[0057] The primary refined brine was adjusted to pH 4 with concentrated hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com