Method for preparing light transmitting concrete through application of optical fiber winding machine technology

A technology of light-transmitting concrete and winding machine, which is used in manufacturing tools, ceramic molding machines, etc., can solve the problems of poor light-transmitting stability, increased production process, poor optical fiber positioning stability, etc., to improve positioning effect, reduce time cost, The effect of improving the light transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

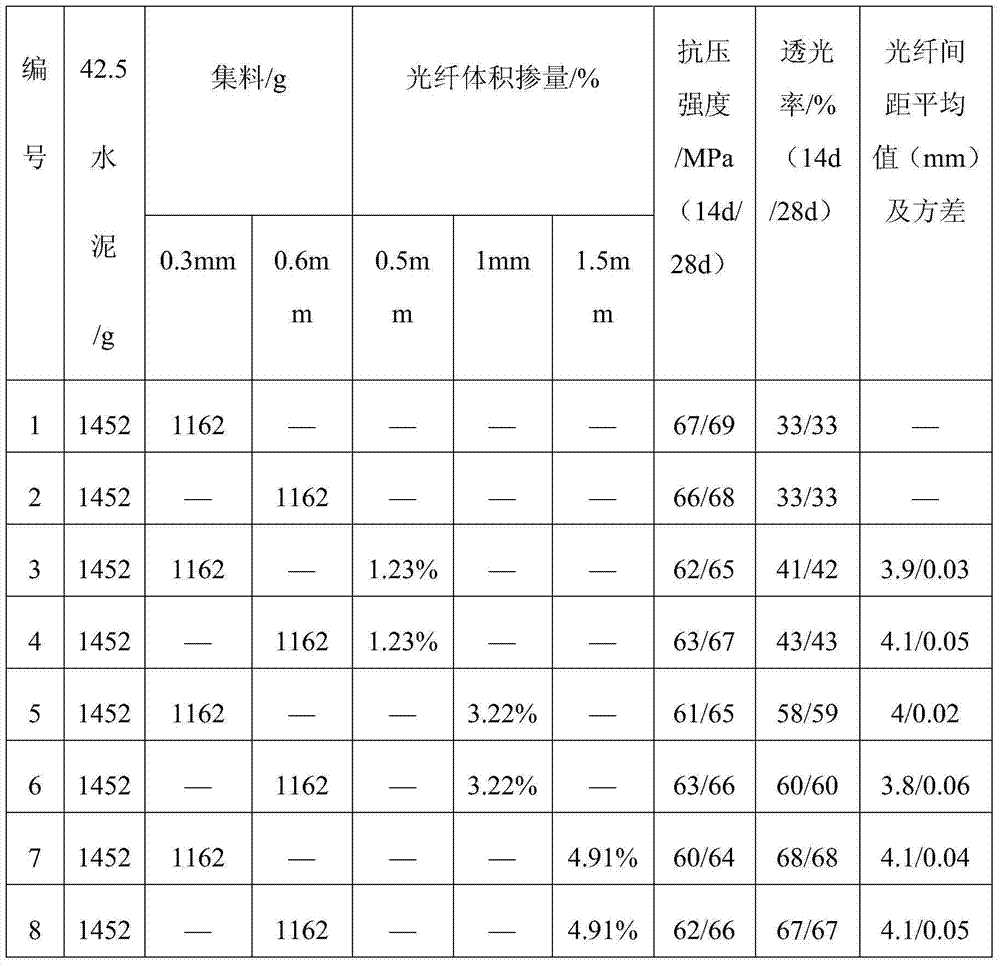

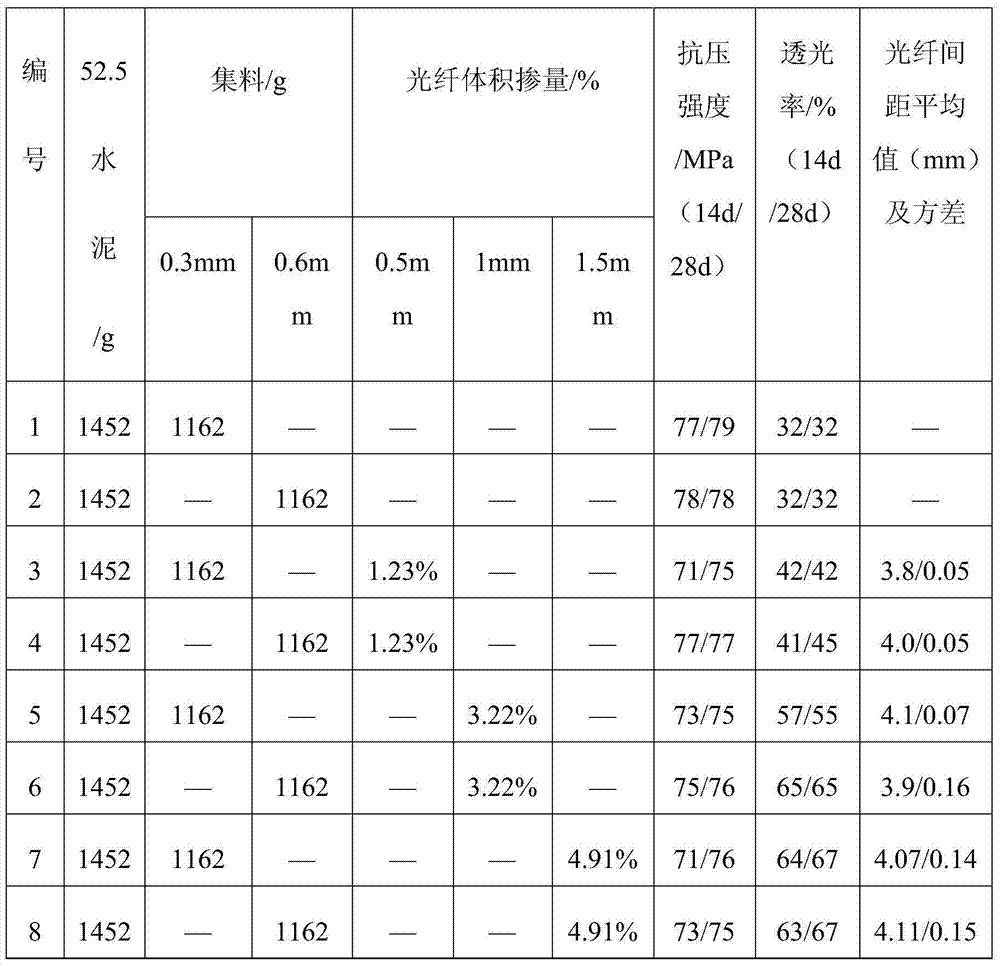

[0033] The raw material composition of mortar in embodiment example 1 and 2 is respectively as follows: In order to reach the cement paste of high fluidity and high strength, select cement to be produced in Tangshan 42.5 quick-hardening sulfoaluminate cement, 3d compressive strength and flexural strength are respectively The cement is 42.9MPa and 8.4MPa and the cement is 52.5 quick-hardening sulfoaluminate cement produced in Tangshan. The 3d compressive strength and flexural strength are 53.9MPa and 10.4MPa respectively; the maximum particle size of the two aggregates selected is not more than 0.3mm and 0.6mm, the prepared mortar has a water-cement ratio of 0.35 and a sand-cement ratio of 0.8. The measured mortar consistency is 16cm and 15cm, and the compressive strength is higher than 60MPa. -8H powder polycarboxylate superplasticizer, the water reducing rate is 30%; the content of defoamer is 0.2%, which is P764 powder defoamer produced by Shenzhen Hairun Chemical Co., Ltd.; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com