Manufacturing process and device for massage physical therapy head

A manufacturing process and technology of physiotherapy head, applied in massage auxiliary products, vibration massage, physiotherapy and other directions, can solve the problems of time-consuming, labor-intensive, cost, damage, etc., to improve the bonding performance, improve the bonding force, and improve the bonding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

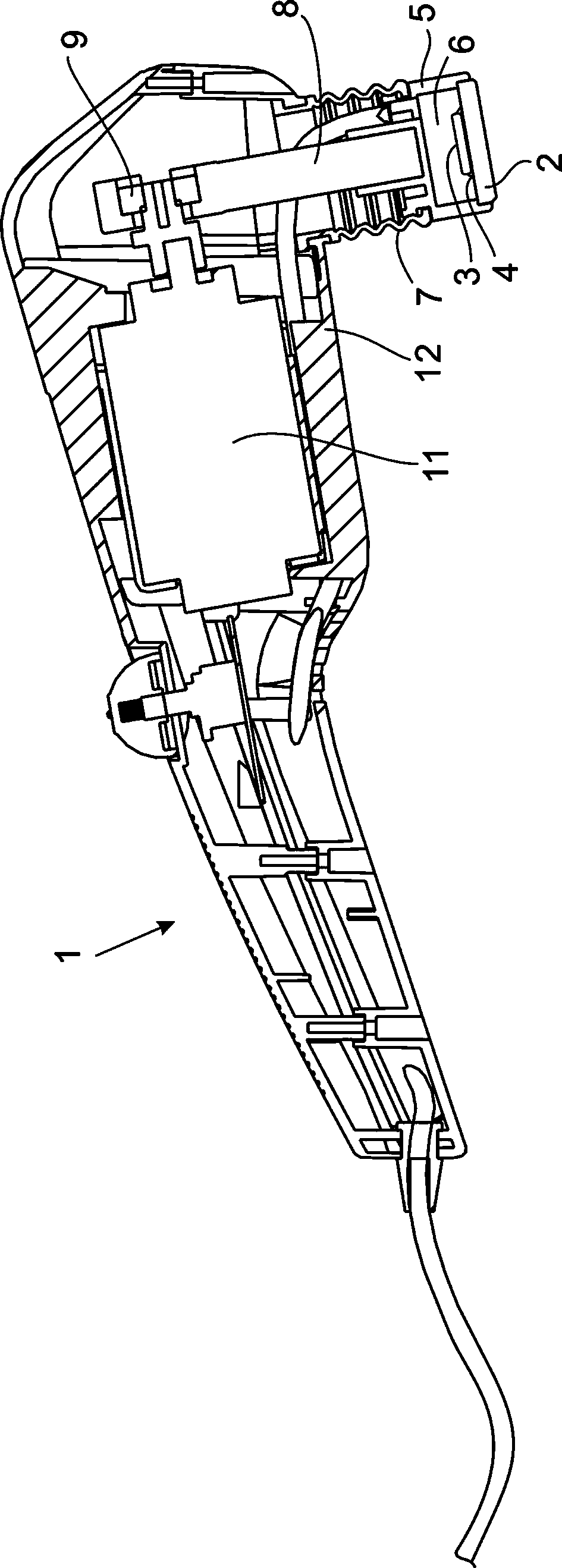

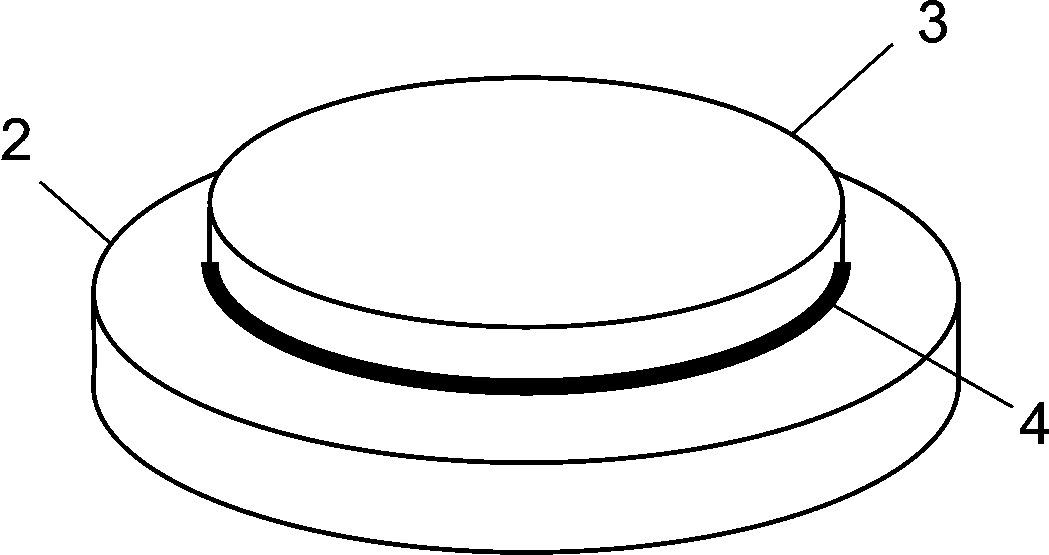

[0116] as attached figure 1 As shown, a massage therapy head includes a piezoelectric ceramic sheet 3 and a sound-transmitting layer 2, one side of the piezoelectric ceramic sheet 3 is plated with metallic silver, and an electrode is installed on the upper and lower sides of the piezoelectric ceramic sheet 3. In connection with the power supply, the manufacturing process steps of the massage therapy head are as follows:

[0117] Step 1: Use cleaning solution to clean the components of the massage therapy head, including the piezoelectric ceramic sheet 3 and the sound-transmitting layer 2;

[0118] Cleaning steps include:

[0119] ①. Cleaning the components with an ultrasonic device filled with cleaning fluid;

[0120] ②. Then rinse the components with pure water;

[0121] ③. Rinse the element with an ultrasonic device filled with purified water;

[0122] ④. Dry the element with a drying oven until the moisture content of the element is less than 0.1%;

[0123] Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com