Loudspeaker reliability test device

A test device and speaker technology, applied in electrical components and other directions, can solve the problems of easy failure, high cost, large space occupation, etc., to avoid line failure, improve service life, and take up less space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

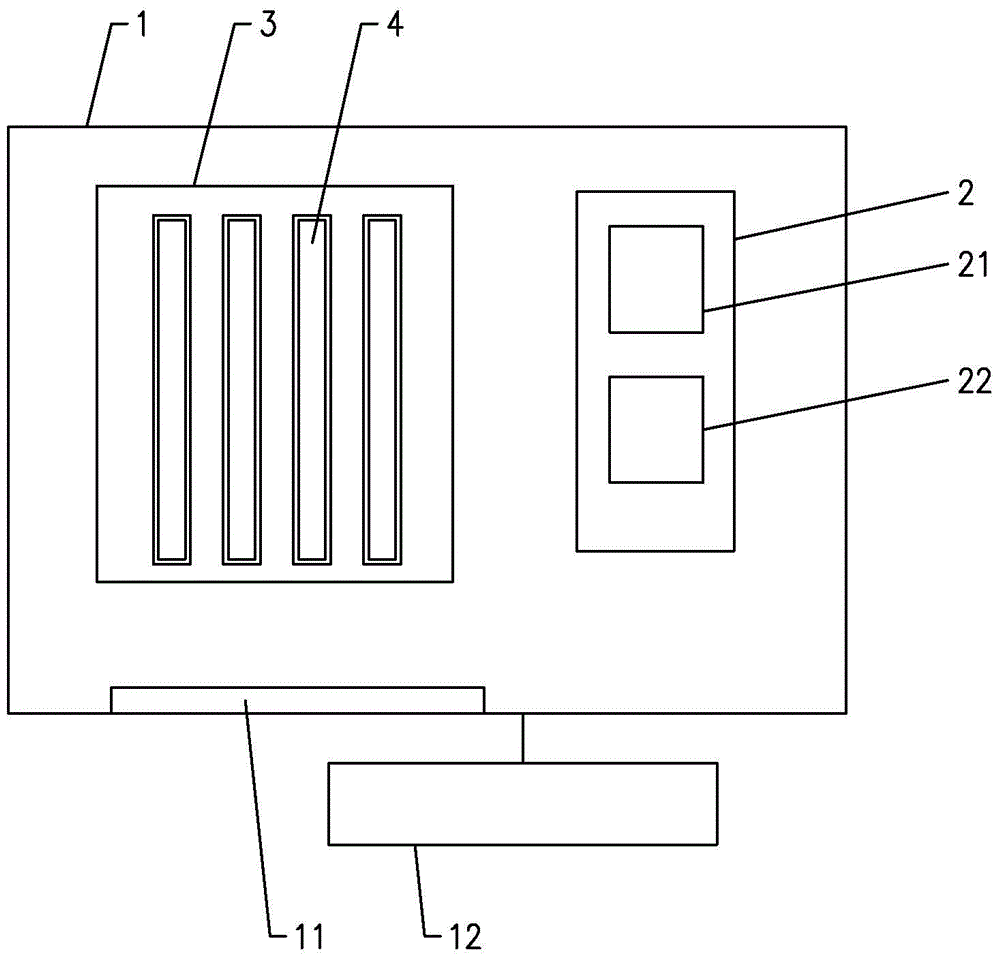

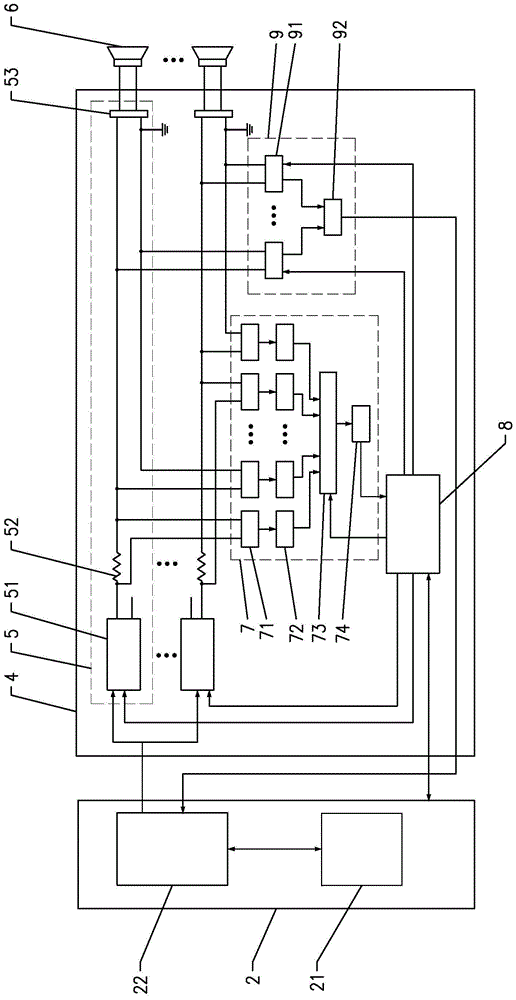

[0020] Such as figure 1 and figure 2 Commonly shown, a loudspeaker reliability testing device. This loudspeaker reliability testing device comprises cabinet 1, is provided with display 11 on cabinet 1 panel, for the convenience of operation, is also provided with the keyboard 12 that is connected with cabinet 1, is provided with computer system 2 in cabinet 1, cabinet among the present embodiment 1 and the computer system 2 directly use industrial computers, and all functional components are placed in the chassis 1, which realizes the miniaturization of the equipment and occupies a small space.

[0021] The computer system 2 is provided with a LabView processing module 21 and an audio card 22. The audio card 22 adopts DELTA66 or MAYA44, and the LabView processing module 21 can edit, store and play test signals in the form of multimedia files, which is convenient and flexible. The interface is realized, the operation is convenient, and the information is clear.

[0022] Als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com