Preparation method of single crystalline silicon solar cell with back polished structure

A solar cell, backside polishing technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems affecting the quality of PN junction, layer unevenness, adverse effects of battery short-circuit current and open-circuit voltage, etc., to improve the photoelectric conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be further described below in conjunction with the accompanying drawings. Of course, the present invention is not limited to this specific embodiment, and general replacements known to those skilled in the art are also covered within the protection scope of the present invention.

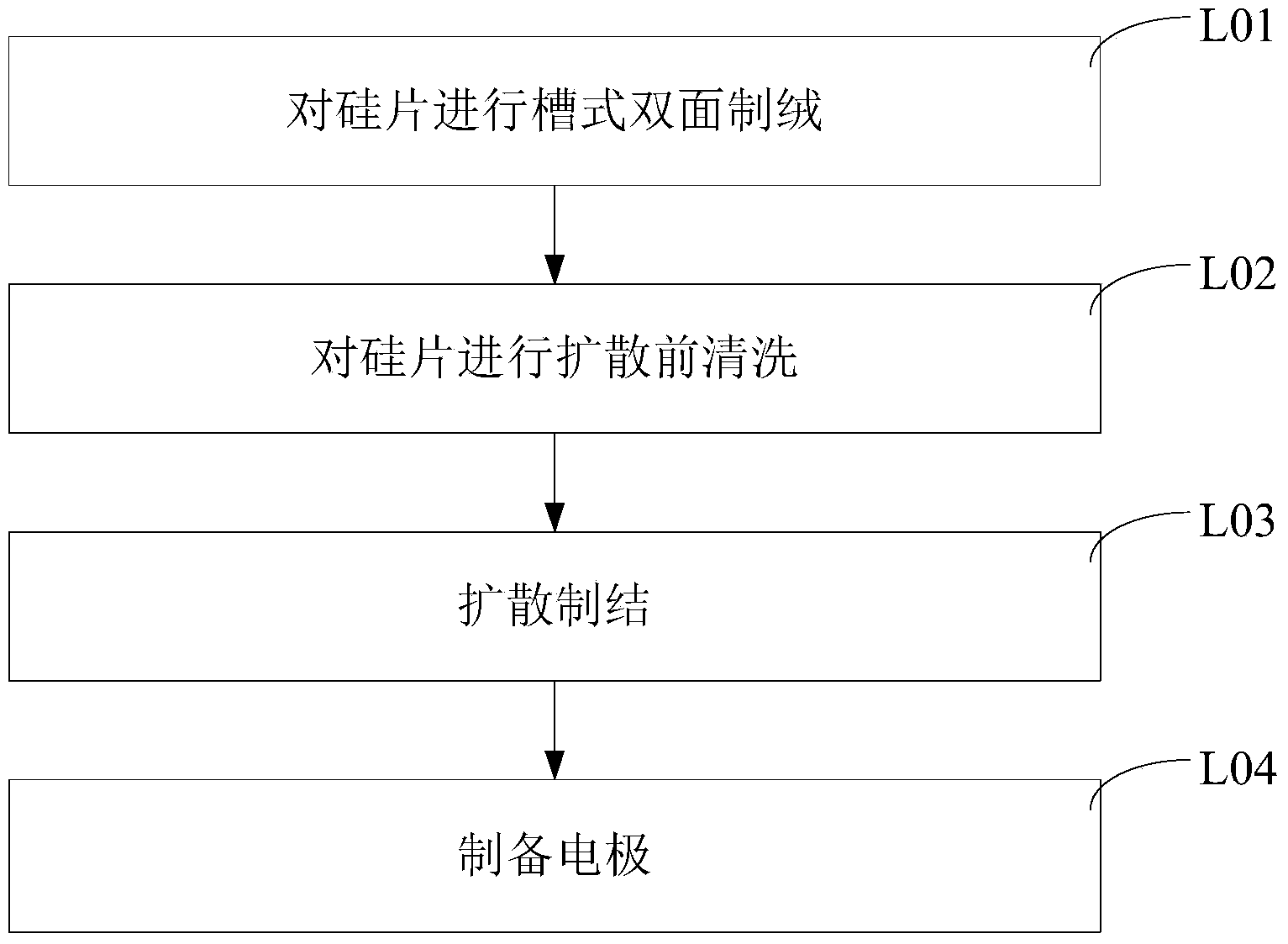

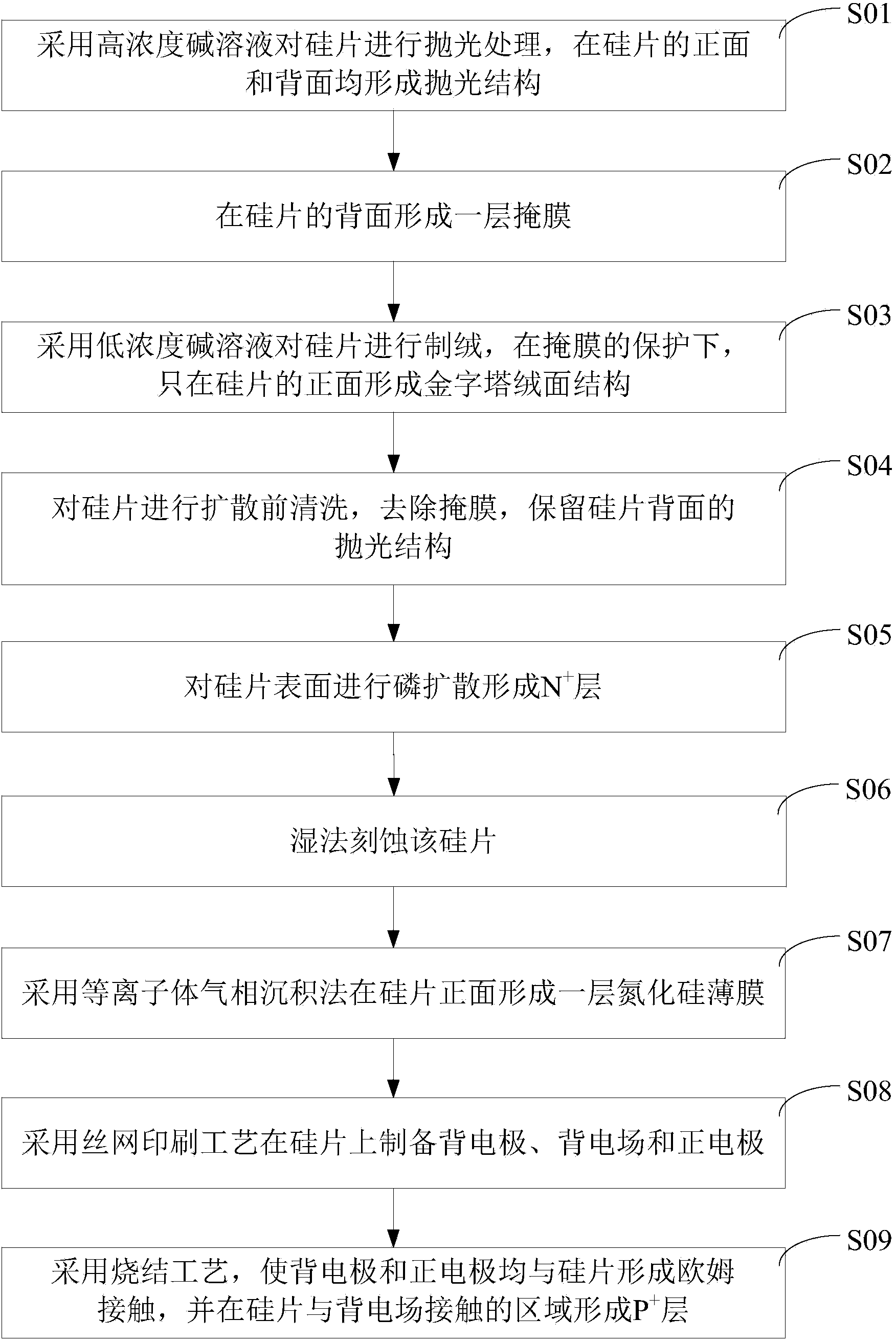

[0036] Below in conjunction with specific embodiment and appended Figure 2-4 The preparation method of the single-crystal silicon solar cell with the rear polished structure of the present invention will be further described in detail. in, figure 2 A schematic diagram of the cross-sectional structure of a solar cell prepared by a method for preparing a single crystal silicon solar cell with a rear polished structure according to a preferred embodiment of the present invention, image 3 It is a schematic flow chart of the preparation method of the back-polished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com