Compound technology for metallization of front side of solar cell

A solar cell and composite process technology, which is applied in the composite process field of solar cell front metallization, can solve problems such as limitations, and achieve the effect of improving product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the production of polysilicon solar cells is taken as an example, and the steps of the composite process of metallizing the front side of the cell are as follows:

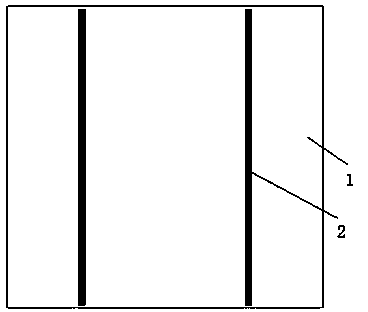

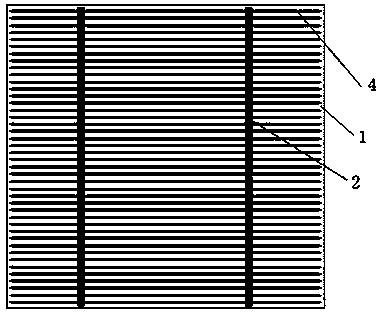

[0028] 1. Design a printing screen with only busbars, and prepare busbars 2 on the polysilicon solar cell 1 by screen printing technology. The width of the busbars is 1.5mm, a total of 2, evenly distributed on the surface of the cell;

[0029] 2. Use WEM technology to prepare thin grid lines 4 in the direction perpendicular to the main grid line 2: select 80 metal wires with a diameter range of 0.01mm-0.03mm as conductive wires, and arrange 80 conductive wires in parallel at equal intervals to conduct electricity. The spacing between the wires is 0.5mm-3mm; then the surface of the conductive wires is uniformly coated with a layer of conductive paste by a coating mechanism; the conductive wires coated with the conductive paste are adhered to On the battery sheet, the thin grid line 4 on th...

Embodiment 2

[0034] In this embodiment, the production of monocrystalline silicon solar cells is taken as an example, and the steps of the composite process of metallizing the front of the cell are as follows:

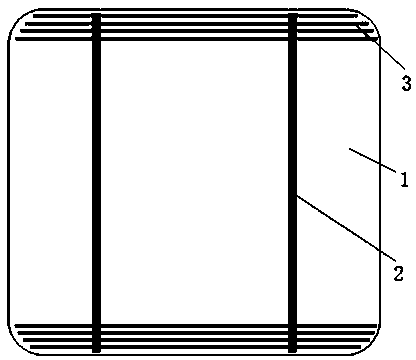

[0035] 1. Design a printing screen with busbars and thin gridlines at the rounded corners, and prepare busbars 2 with a width of 1.5mm on the monocrystalline silicon solar cell 1 by screen printing technology, a total of 2 pieces , and at the same time, use screen printing technology to prepare thin grid lines 3 in the arc-shaped chamfering area of the edge of the battery sheet, 4 on each side, and the closest thin grid line 3 is 1.5mm away from the edge of the battery sheet;

[0036] 2. Use WEM technology to prepare thin grid lines 4 in the direction perpendicular to the main grid line 2: select 60 metal wires with a diameter range of 0.01mm-0.03mm as conductive wires, and arrange 60 conductive wires in parallel at equal intervals to conduct electricity. The spacing between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com