A circular seam welding device and a circular seam welding method for aircraft pipeline parts

A technology for circumferential seam welding and aircraft pipe, applied in the field of welding processing, can solve the problems of single use function, increased difficulty in tooling management, long production cycle, etc., and achieves the effects of complete functions, light weight and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] This embodiment is a circular seam welding device and a circular seam welding method for aircraft pipeline parts.

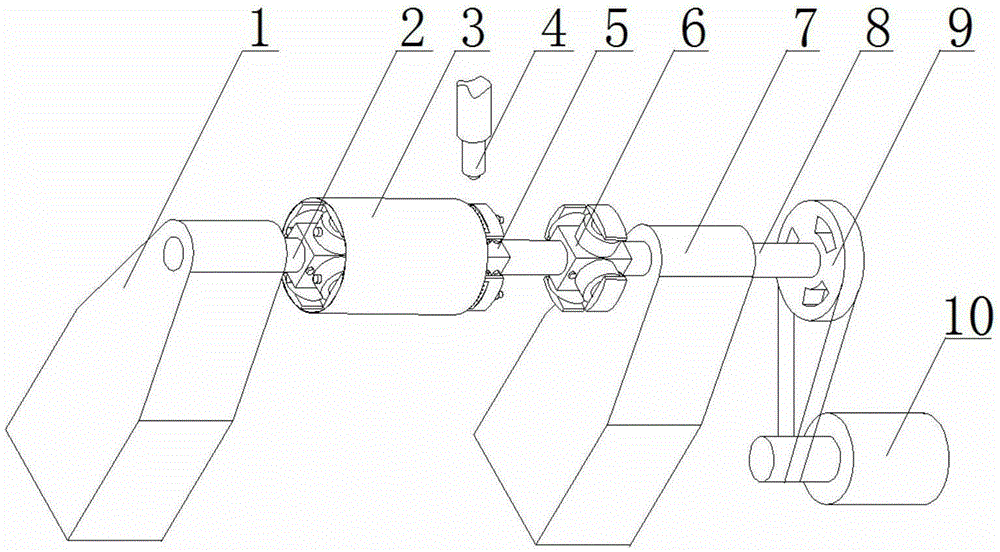

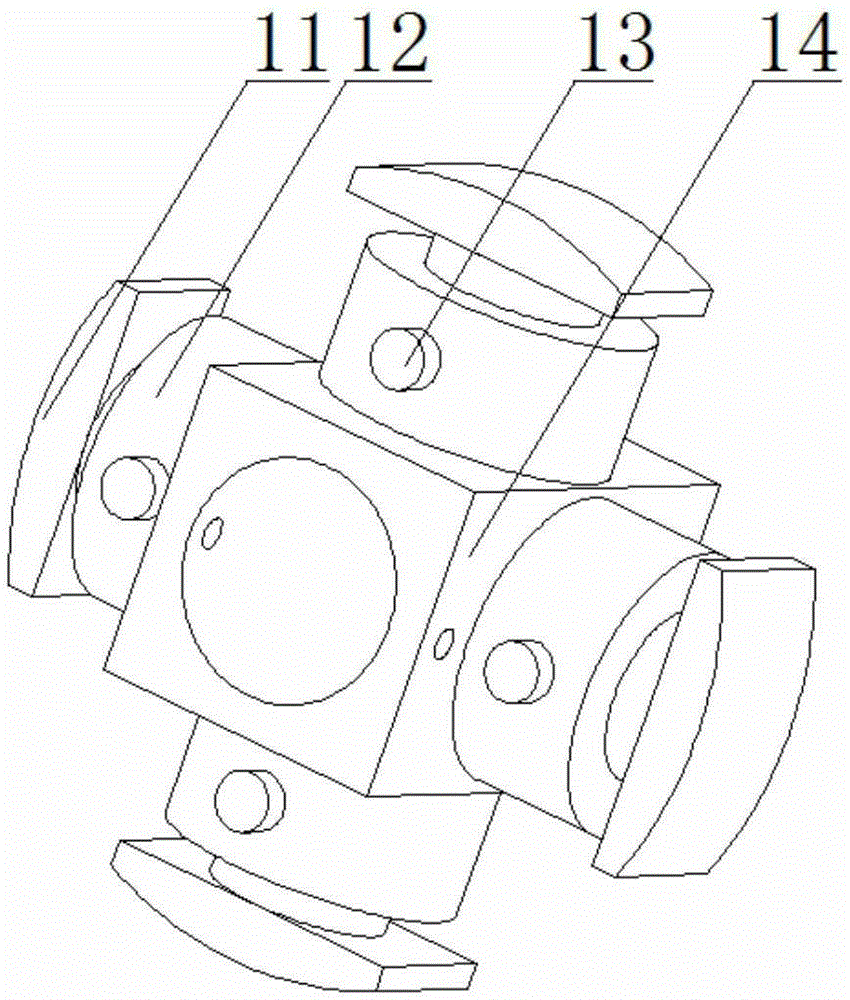

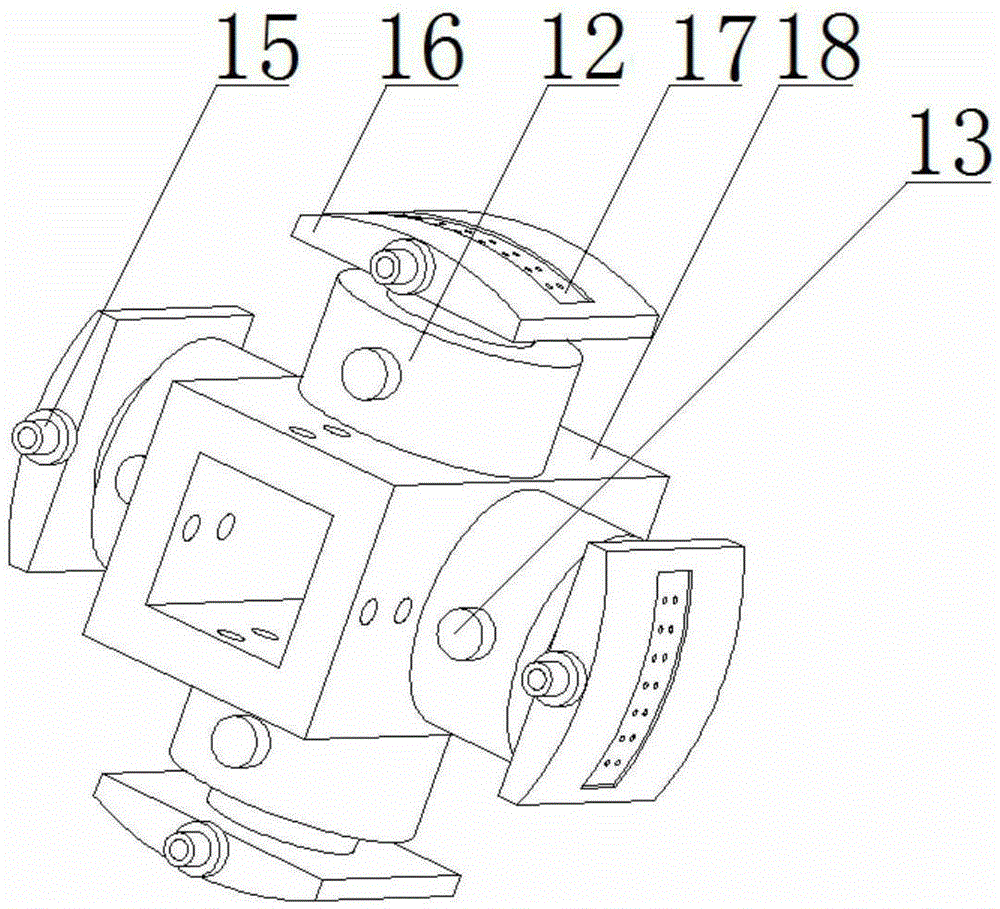

[0030] refer to Figure 1 to Figure 9, the circumferential seam welding device for pipeline parts in this embodiment includes a first base 7, a second base 1, a first main shaft 8, a second main shaft 2, a first inner support unit 5, a second inner support unit 6, and a pulley 9. Power unit 10, welding robot arm 4, synchronous hydraulic pump console 20, the first base 7 is fixedly installed between the power unit 10 and the second base 1, and the first main shaft 8 is installed on the first base 7 The end of the cylindrical section of the first main shaft 8 is equipped with a pulley 9, and is installed on the same side of the first base 7 as the power unit 10, and the first inner support unit 5 is installed at the end of the square section of the first main shaft 8, the first The inner support unit 5 is located in the weld seam area of the pipe piece 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com