Method and device for processing radioactive wastewater

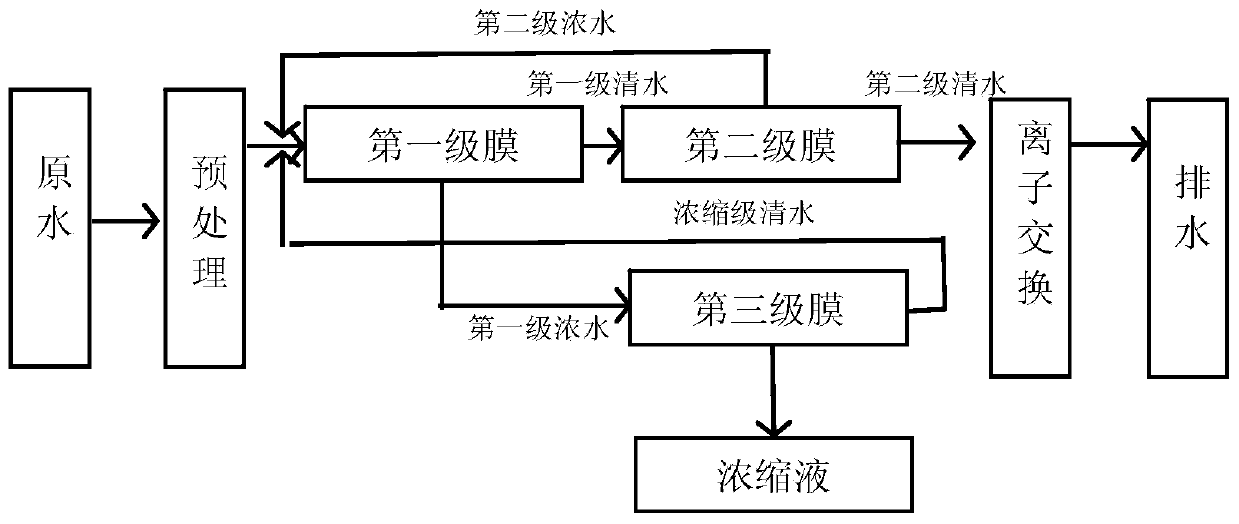

A technology for radioactive wastewater and treatment methods, which is applied in radioactive purification, radioactive pollutants, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

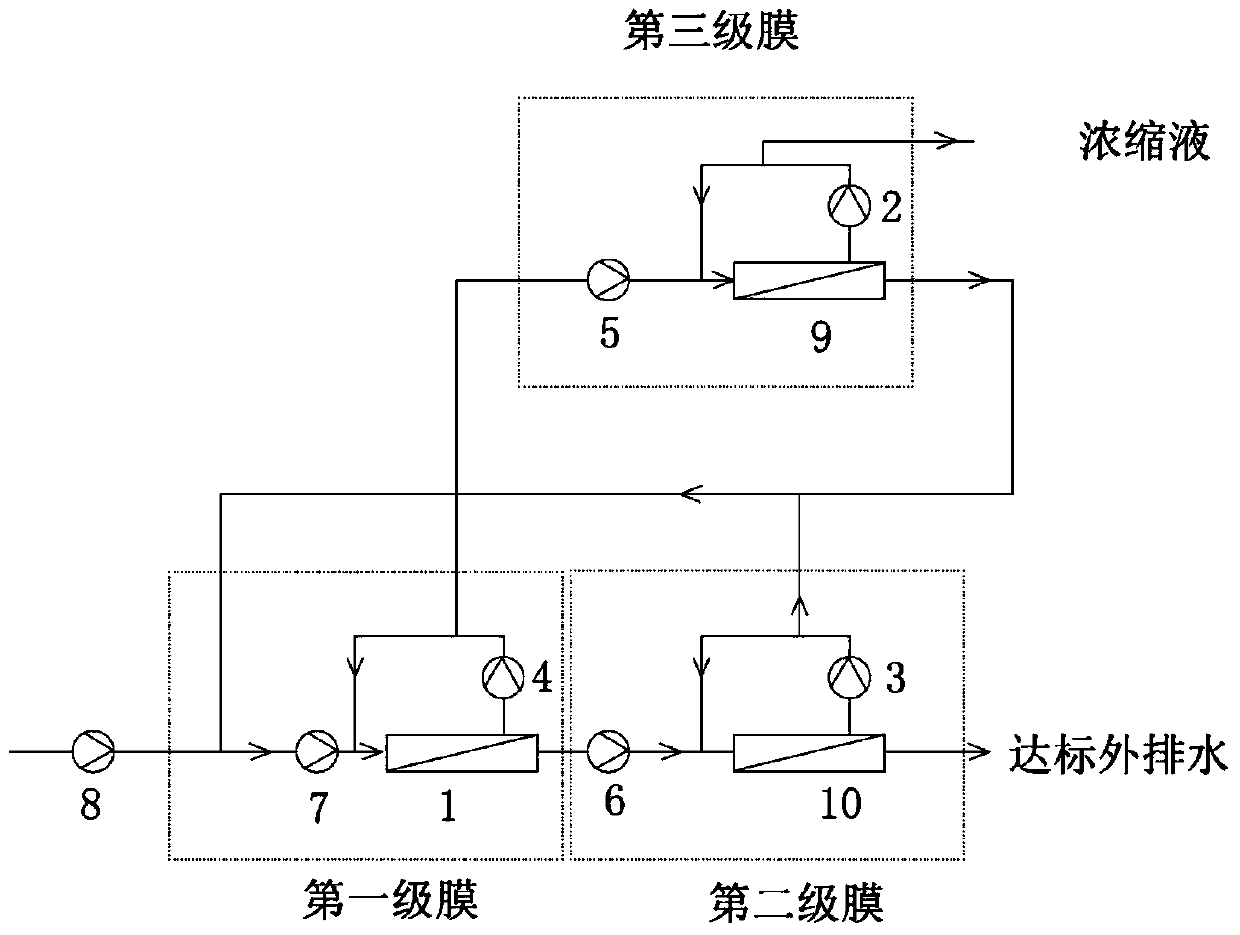

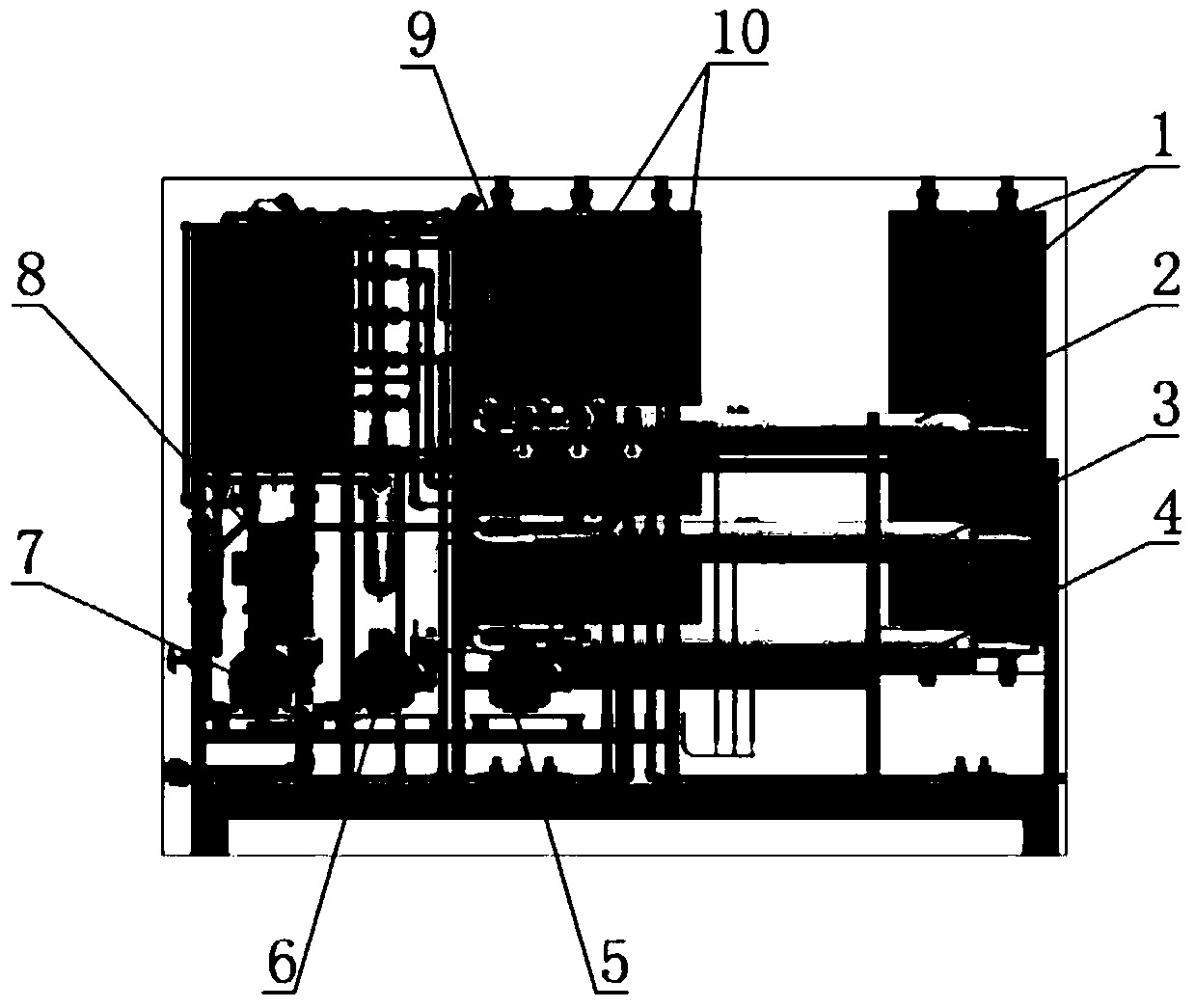

[0042] Start the raw water supply pump, and send 10 tons of wastewater with a salt content of 5g / L and a total beta activity of 50,000Bq / L (the maximum level that the concentration of radioactive wastewater from nuclear power plants and nuclear facilities may reach) Figure 2B The device shown performs processing.

[0043] Fully open the concentrated water outlet valve of the first-stage membrane module, start the first-stage high-pressure pump (frequency conversion control, frequency conversion frequency 50Hz), start the first-stage circulating pump with a delay of 3 minutes, and adjust the concentrated water outlet valve of the first-stage membrane module Make the outlet pressure of the first stage high pressure pump reach 5.5MPa. Fully open the concentrated water outlet valve of the second-stage membrane module, start the second-stage high-pressure pump, start the second-stage circulating pump (frequency conversion control, frequency conversion frequency 50Hz) with a delay of 3...

Embodiment 2

[0048] According to the equipment and operating conditions used in Example 1, 10 tons of wastewater with a salt content of 5 g / L and a total beta activity of 10000 Bq / L were treated.

[0049] After treatment, the total beta activity of the clean water discharged from the first-stage membrane module is 100Bq / L, the activity of the clean water discharged from the second-stage membrane module is 2Bq / L, and the decontamination factor of the two-stage membrane system is 5000. The volume of the concentrated liquid that needs to be cemented is 0.4 cubic meters (with a salt content of 125g / L), so the concentration of radioactive waste water in the entire process is 25 times.

[0050] If the clean water discharged from the second-stage membrane module is sent to the ion exchanger for further processing, the total volume of clean water that can be obtained is 9.6 tons, and the final total β activity of the clean water is 0.1Bq / L, so the entire process is depleted. The pollution factor is 100...

Embodiment 3

[0053] According to the device and operating conditions used in Example 1, 10 tons of wastewater with a salt content of 5 g / L and a total beta activity of 5000 Bq / L were treated.

[0054] After treatment, the total beta activity of the clean water discharged from the first-stage membrane module is 50Bq / L, the activity of the clean water discharged from the second-stage membrane module is 1Bq / L, and the decontamination factor of the two-stage membrane system is 5000. The volume of the concentrated liquid that needs to be cemented is 0.4 cubic meters (with a salt content of 125g / L), so the concentration of radioactive waste water in the entire process is 25 times.

[0055] If the clean water discharged from the second-stage membrane module is sent to the ion exchanger for further treatment, the total volume of clean water that can be obtained is 9.6 tons, and the total β activity of the final clean water is 0.05Bq / L, so the entire process is depleted. The pollution factor is 100000. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radioactivity | aaaaa | aaaaa |

| Radioactivity | aaaaa | aaaaa |

| Radioactivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com