Genetic engineering acetic acid bacteria of overexpressing coenzyme PQQ (pyrroloquinoline quinone) synthetic proteins and application of bacteria

A genetic engineering, overexpression technology, applied in the direction of bacteria, vinegar preparation, microbial-based methods, etc., can solve undiscovered problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

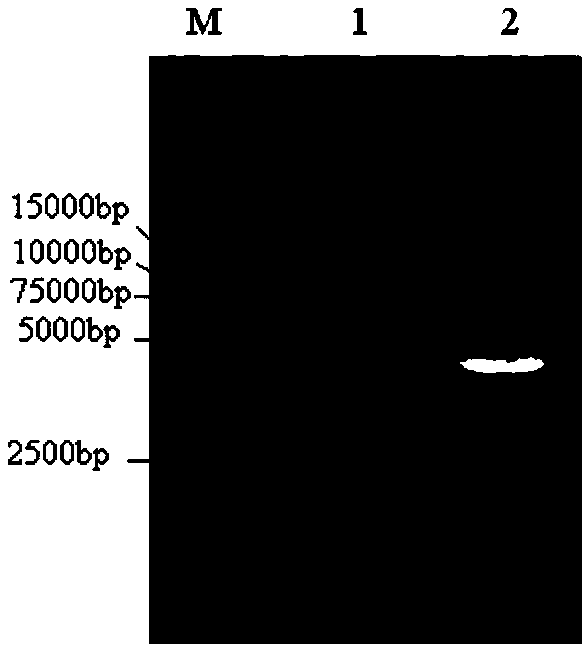

[0061] Embodiment 1 prepares the genetically engineered Acetobacter pasteurianus that contains recombinant plasmid pBBR-Padh-pqq

[0062] (1) Construction of recombinant plasmid pBBR-Padh

[0063] The genome of Acetobacter pasteurianus CGMCC3089 (purchased from the General Microbiology Center of China Microbiological Culture Collection Management Committee, address: No. 3, No. 1, Beichen West Road, Chaoyang District, Beijing, Institute of Microbiology, Chinese Academy of Sciences, postcode 100101. Authorized patent number: ZL200810053141) is Template, using primers Padh-1 and Padh-2 for PCR, amplified to obtain the Padh sequence of the alcohol dehydrogenase promoter, the PCR reaction system is as follows:

[0064]

[0065] The PCR reaction conditions were: pre-denaturation at 95°C for 5 minutes, 30 seconds at 94°C, 20 seconds at 56°C, 30 seconds at 72°C, and 10 minutes at 72°C after 26 cycles.

[0066] Alcohol dehydrogenase promoter Padh sequence and plasmid pBBR1MCS-4 (Ko...

Embodiment 2

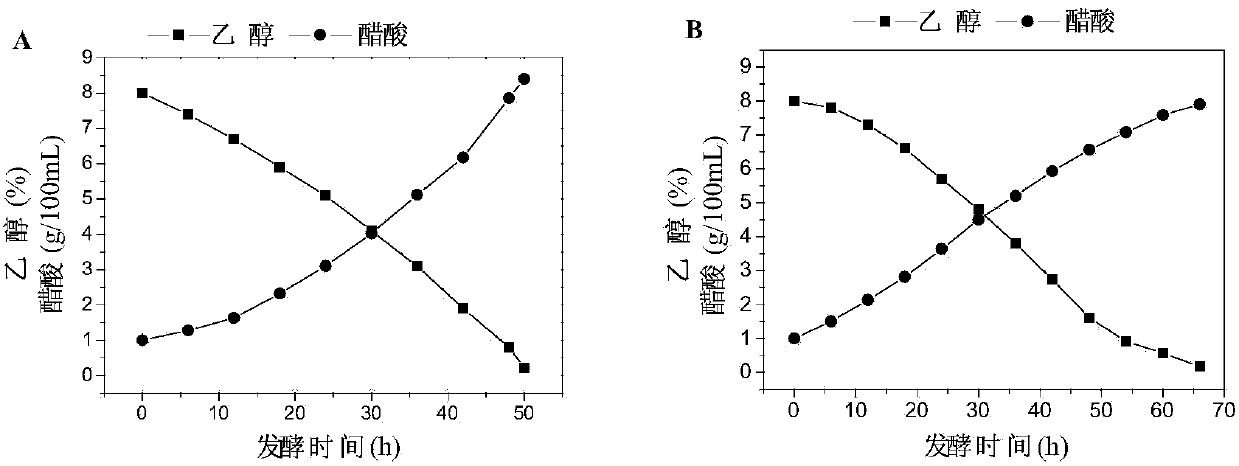

[0078] Embodiment 2 utilizes the Acetobacter pasteurianus CGMCC3089 genetic engineering bacterium containing recombinant plasmid pBBR-Padh-pqq to produce acetic acid by fermentation

[0079] (1) Preparation of seed solution

[0080] Acetobacter pasteurianus CGMCC3089 genetically engineered bacteria and Acetobacter pasteurianus CGMCC3089 original bacteria containing the recombinant plasmid pBBR-Padh-pqq were taken from the slant and inoculated into the seed medium, and cultured on a shaker at 30°C and 160 rpm for 24 hours. According to the 10% (v / v) inoculum size, transfer to fresh seed medium for scale-up culture.

[0081] The composition of the seed medium: glucose 20g / L, yeast extract 15g / L, ethanol 3.5% (v / v), and the rest is water.

[0082] (2) Acetic fermentation

[0083] According to the inoculum amount of 10%, inoculate the seed liquid into the fermenter containing the fermentation medium, and carry out acetic acid fermentation under the condition of 30°C.

[0084] C...

Embodiment 3

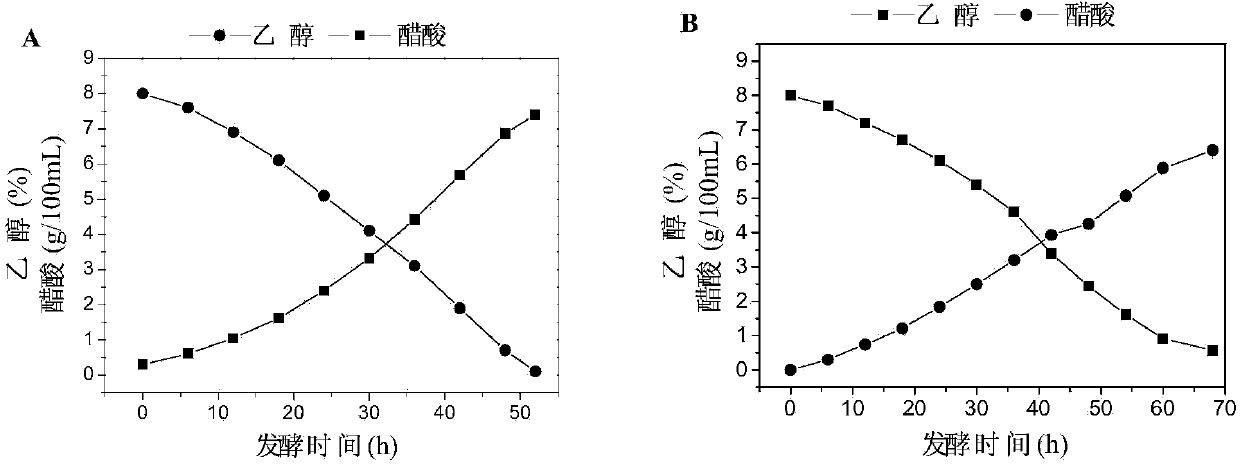

[0088] Example 3 Production of Apple Cider Vinegar by Fermentation of Acetobacter pasteurianus CGMCC3089 Genetic Engineering Bacteria Containing Recombinant Plasmid pBBR-Padh-pqq

[0089] (1) Preparation of seed solution

[0090] Take the Acetobacter pasteurianus CGMCC3089 genetically engineered bacteria containing the recombinant plasmid pBBR-Padh-pqq from the slant in the seed medium, and culture it on a shaker at 30°C and 160 rpm for 25 hours. According to the 10% (v / v) inoculum size, transfer to fresh seed medium for scale-up culture.

[0091] The composition of seed medium: glucose 20g / L, yeast extract 15g / L, ethanol 3.5% (v / v), and the rest is water.

[0092] (2) Apple cider vinegar fermentation

[0093] According to the inoculum amount of 10% (v / v), it was inoculated into the fermenter containing cider, and the apple cider vinegar was fermented at 30°C. The ethanol content in cider is 8% (v / v).

[0094] The Acetobacter pasteurianus CGMCC3089 genetically engineered b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com