Pulp feeding machine for viscose filaments

A silk pulp and feeding machine technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of no safety protection structure, large safety hazards, and particularly high requirements for ash powder, and achieve the effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples.

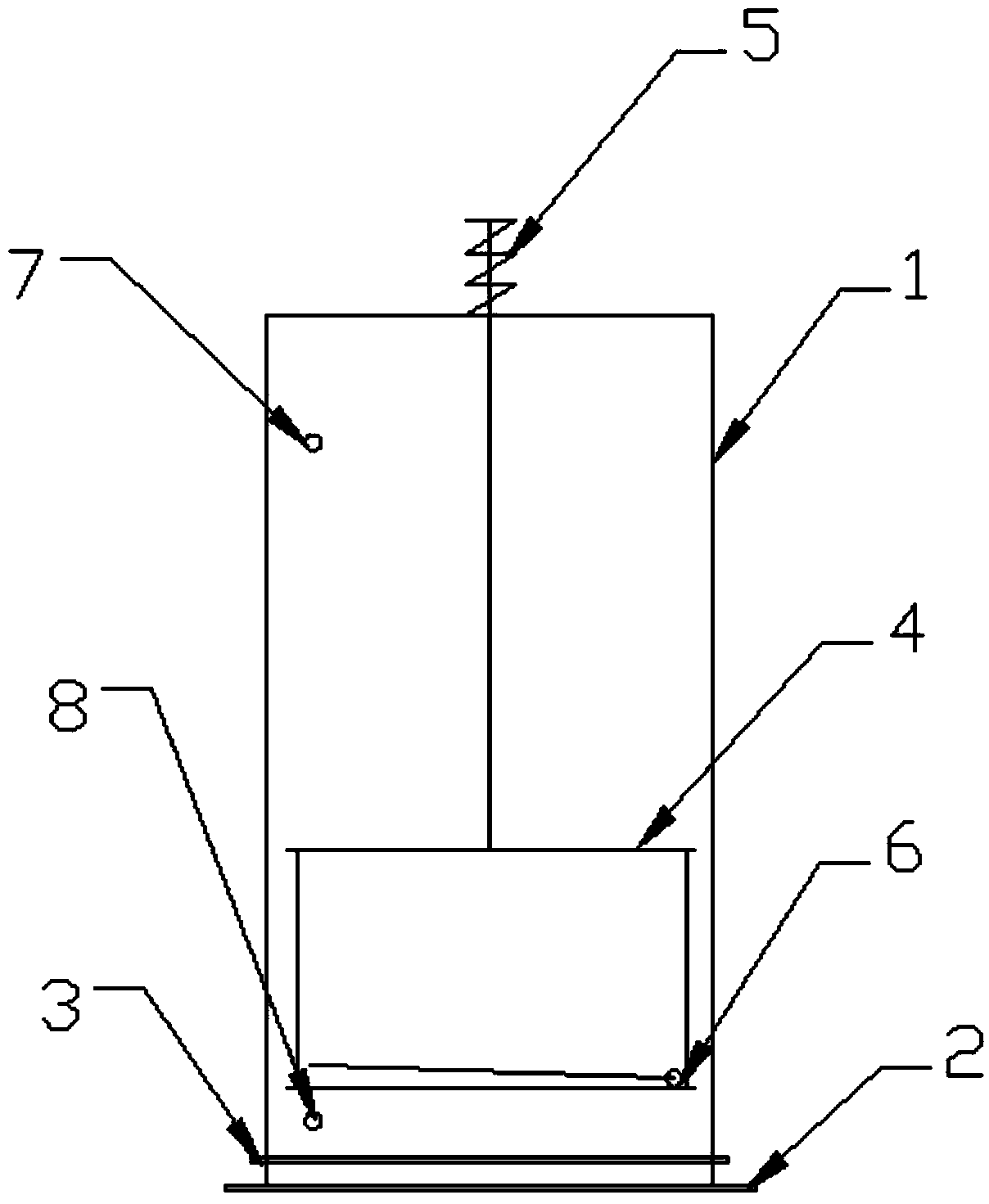

[0019] Such as figure 1 Shown, a kind of viscose filament pulp feeding machine of the present invention, it comprises casing 1, bottom plate 2, safety baffle 3, hanging basket 4, lifting device 5 and automatic rotation device 6, and described lifting device 5 installs In the casing 1, the hanging basket 4 is installed at the lower end of the lifting device 5, the automatic rotation device 6 is installed at the lower end of the hanging basket 4, the bottom plate 2 is installed at the lower end of the casing 1, and the safety baffle 3 is installed Set on the case 1 and higher than the bottom plate 2. It also includes the upper limiter 7 of the lifting device and the lower limiter 8 of the lifting device, the upper limiter 7 of the lifting device and the lower limiter 8 of the lifting device are on the same vertical line, and the upper limiter 7 of the lifting device is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com