Deferasirox granules and preparation method thereof

A technology of deferasirox and granules, applied in the field of pharmaceutical preparations, can solve the problems of time-consuming and inconvenient use, limited widespread use, poor compliance and the like, and achieves the effects of convenient administration, easy dose division, and fast absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

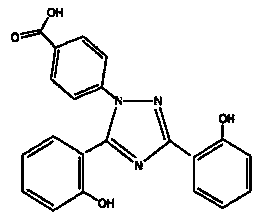

Image

Examples

Embodiment 1

[0028] Embodiment 1 (prescription quantity is 1000 bags)

[0029] Raw material dosage (g)

[0030] Deerasirox 125

[0031] Lactose 590

[0032] Microcrystalline Cellulose 590

[0033] 10% PVP K30 aqueous solution 75

[0034] Crospovidone 75

[0035] Sodium Lauryl Sulfate 3

[0036] Aspartame 42

[0037] Preparation process: Weigh the prescribed amount of deferasirox, lactose, microcrystalline cellulose, crospovidone, sodium lauryl sulfate and aspartame, pass through a 80-100 mesh sieve and mix thoroughly. Add an appropriate amount of 10% PVP K30 aqueous solution and stir well to make a soft material. Extrude the soft material through a 24-mesh sieve to make wet granules, and dry at 60°C for 2 hours. The dried granules are passed through a 18-mesh sieve for granulation, quality inspection, and packaging (1.5g / bag) after passing the test.

Embodiment 2

[0038] Embodiment 2 (prescription quantity is 1000 bags)

[0039] Raw material dosage (g)

[0040] Deerasirox 125

[0041] Lactose 787

[0042] Microcrystalline cellulose 393

[0043] 10% PVP K30 aqueous solution 75

[0044] Crospovidone 75

[0045] Sodium Lauryl Sulfate 3

[0046] Aspartame 42

[0047] Preparation process: Weigh the prescribed amount of deferasirox, lactose, microcrystalline cellulose, crospovidone, sodium lauryl sulfate and aspartame, pass through a 80-100 mesh sieve and mix thoroughly. Add an appropriate amount of 10% PVP K30 aqueous solution and stir well to make a soft material. Extrude the soft material through a 24-mesh sieve to make wet granules, and dry at 60°C for 2 hours. The dried granules are passed through a 18-mesh sieve for granulation, quality inspection, and packaging (1.5g / bag) after passing the test.

Embodiment 3

[0048] Embodiment 3 (prescription quantity is 1000 bags)

[0049] Raw material dosage (g)

[0050] Deerasirox 125

[0051] Lactose 885

[0052] Microcrystalline Cellulose 295

[0053] 10% PVP K30 aqueous solution 75

[0054] Crospovidone 75

[0055] Sodium Lauryl Sulfate 3

[0056] Aspartame 42

[0057]Preparation process: Weigh the prescribed amount of deferasirox, lactose, microcrystalline cellulose, crospovidone, sodium lauryl sulfate and aspartame, pass through a 80-100 mesh sieve and mix thoroughly. Add an appropriate amount of 10% PVP K30 aqueous solution and stir well to make a soft material. Extrude the soft material through a 24-mesh sieve to make wet granules, and dry at 60°C for 2 hours. The dried granules are passed through a 18-mesh sieve for granulation, quality inspection, and packaging (1.5g / bag) after passing the test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com