Two-dimensional vertical cavity surface emitting laser array

A vertical-cavity surface-emitting laser technology, applied in the field of laser arrays, can solve problems such as limiting high-density integration applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

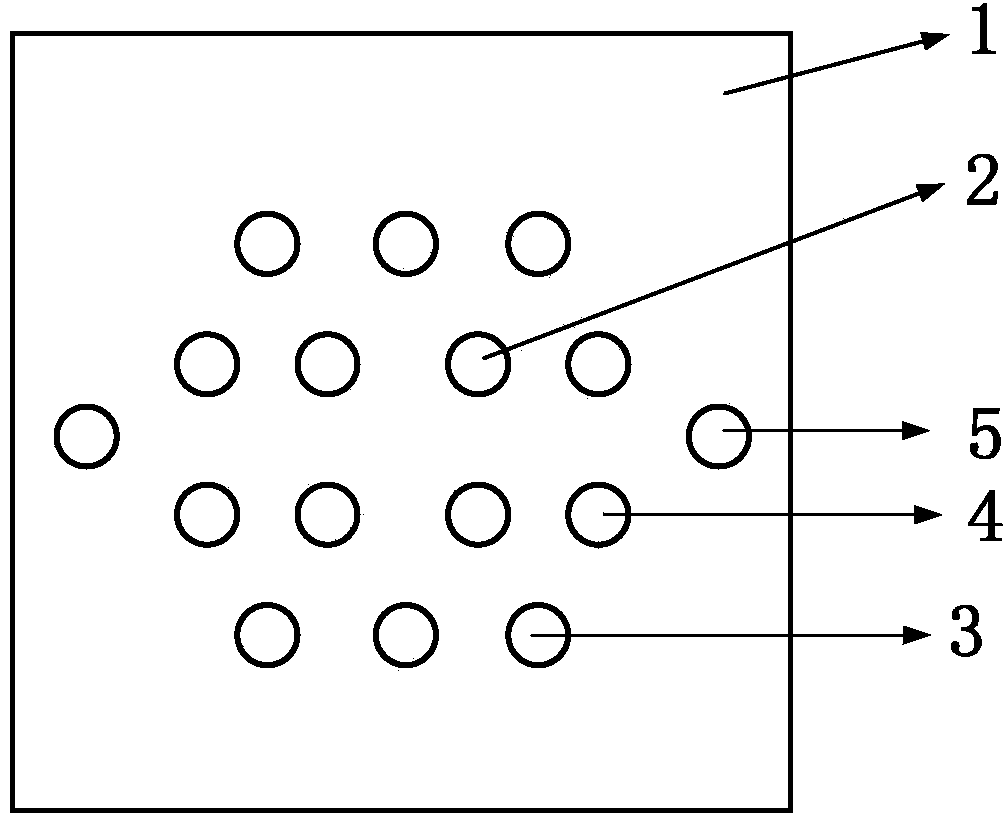

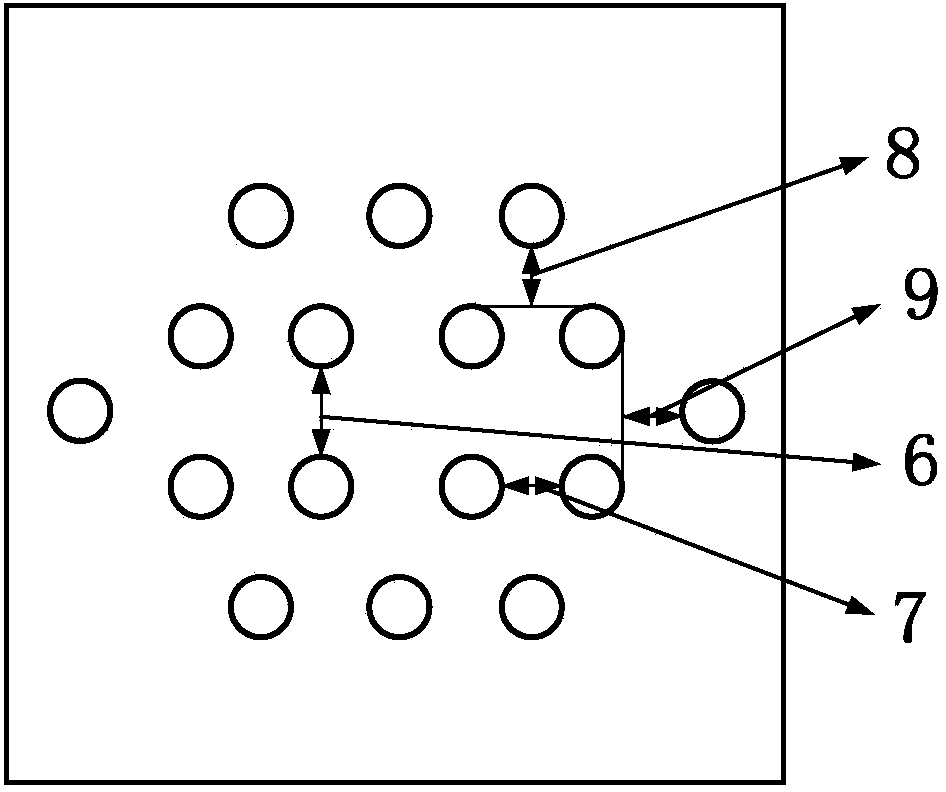

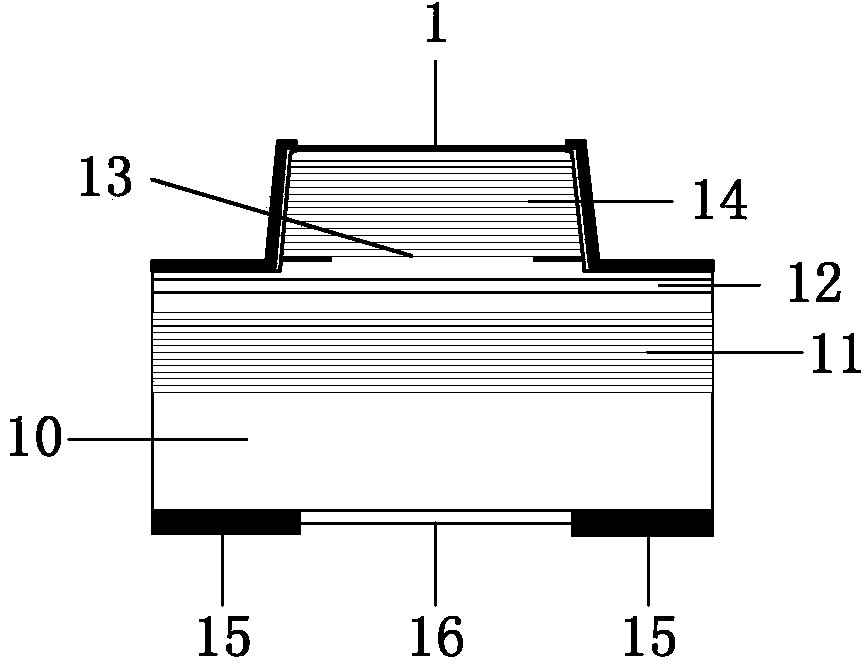

[0018] Such as Figure 1-3 As shown, this two-dimensional vertical cavity surface-emitting laser array includes a surface electrode 1 and n unit laser devices, n is an integer greater than 3, and the unit laser devices are distributed on the surface electrodes, and the unit laser devices include (n -2) 2 2 central unit laser devices, (n-1)*2 horizontal peripheral unit laser devices 3, (n-2)*2 vertical peripheral unit laser devices 4, 2 edge unit laser devices 5, each unit laser The diameter of the active area of the component is d and the light exit aperture is r, the distance 6 between two adjacent central area unit laser devices is D, D>d, the vertical peripheral unit laser device and the adjacent central area unit laser device are in the On the same horizontal line and the distance 7 between the two is d, the horizontal peripheral unit laser device is located on the mid-perpendicular line of two adjacent central area unit laser devices and the distance 8 from the mid-sag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com