Lithium battery and preparation method thereof

A lithium battery and lithium salt technology, applied in the manufacture of electrolyte batteries, batteries, secondary batteries, etc., can solve the problems of loss of electrochemical activity, battery volume expansion, volume increase, etc., and achieve rapid migration, high rapid migration, Improved stability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

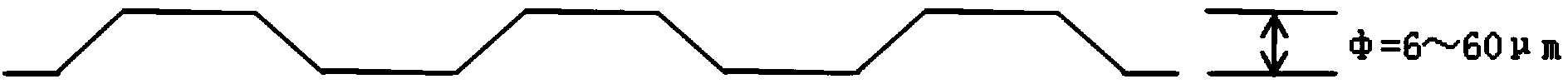

Image

Examples

Embodiment 1

[0048] An embodiment of the lithium battery of the present invention, the lithium battery described in this embodiment is prepared by the following method:

[0049] (1) Production of positive electrode sheet: lithium cobalt oxide (LiCoO 2 ) is the positive electrode active material, mixed with the binder PVDF and the conductive agent Super-P in NMP at a mass ratio of 95:2:3 and stirred evenly to make a positive electrode slurry, with a mass ratio of 33.0mg / cm 2 The density of the positive electrode slurry is double-coated on an aluminum foil with a thickness of 16 μm and a length of 168 mm. The lengths of the double-sided coating of the positive electrode slurry on the aluminum foil are 130 mm and 152 mm, respectively. 42mm, thickness of 0.107mm pole piece, and weld the positive pole lug to obtain the positive pole piece with the positive pole diaphragm attached to the surface;

[0050] (2) Fabrication of the negative electrode current collector substrate: Take 9 μm copper fo...

Embodiment 2

[0056] An embodiment of the lithium battery of the present invention, the lithium battery described in this embodiment is prepared by the following method:

[0057] (1) Production of the positive electrode sheet: nickel-cobalt lithium manganate (LiNi) with a gram capacity of 146mAh / g 0.4 co 0.2 mn 0.4 o 2 ) is the positive electrode active material, mixed with the binder PVDF and the conductive agent Super-P in NMP at a mass ratio of 94.5:2:3.5 to make a positive electrode slurry, with a mass ratio of 30.0mg / cm 2 The density of the positive electrode slurry is double-coated on an aluminum foil with a thickness of 16 μm and a length of 168 mm. The lengths of the double-sided coating of the positive electrode slurry on the aluminum foil are 130 mm and 152 mm, respectively. 42mm, thickness of 0.107mm pole piece, and weld the positive pole lug to obtain the positive pole piece with the positive pole diaphragm attached to the surface;

[0058] (2) Production of negative electro...

Embodiment 3

[0064] An embodiment of the lithium battery of the present invention, the lithium battery described in this embodiment is prepared by the following method:

[0065] (1) Production of positive electrode sheet: lithium manganate (LiMnO) with a gram capacity of 100mAh / g 2 ) is the positive electrode active material, mixed with the binder PVDF and the conductive agent Super-P in NMP at a mass ratio of 94.5:2:3.5 to make a positive electrode slurry, with a mass ratio of 27.0mg / cm 2 The density of the positive electrode slurry is double-coated on an aluminum foil with a thickness of 16 μm and a length of 168 mm. The lengths of the double-sided coating of the positive electrode slurry on the aluminum foil are 130 mm and 152 mm, respectively. 42mm, thickness of 0.102mm pole piece, and weld the positive pole lug to obtain the positive pole piece with the positive pole diaphragm attached to the surface;

[0066](2) Production of the negative electrode current collector base: Cut 16 μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com