Multifunctional numerical control filament winder

A numerical control winding machine, multi-functional technology, applied in the direction of coil manufacturing, electrical components, and conveying filamentous materials, etc., can solve the problems of inaccurate control of the number of winding coils, uneven wiring, low degree of automation, etc., to achieve saving Labor, efficiency improvement, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

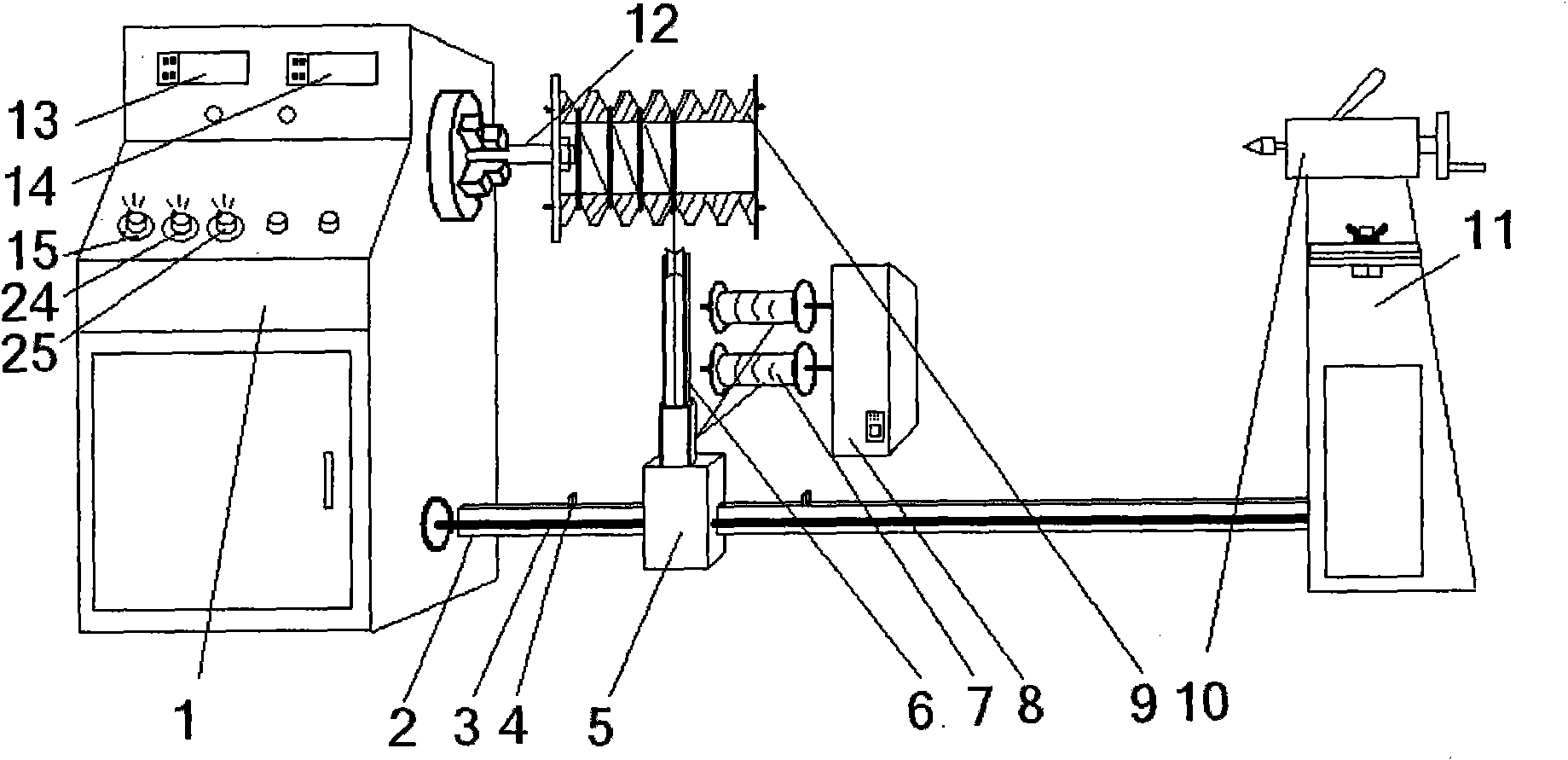

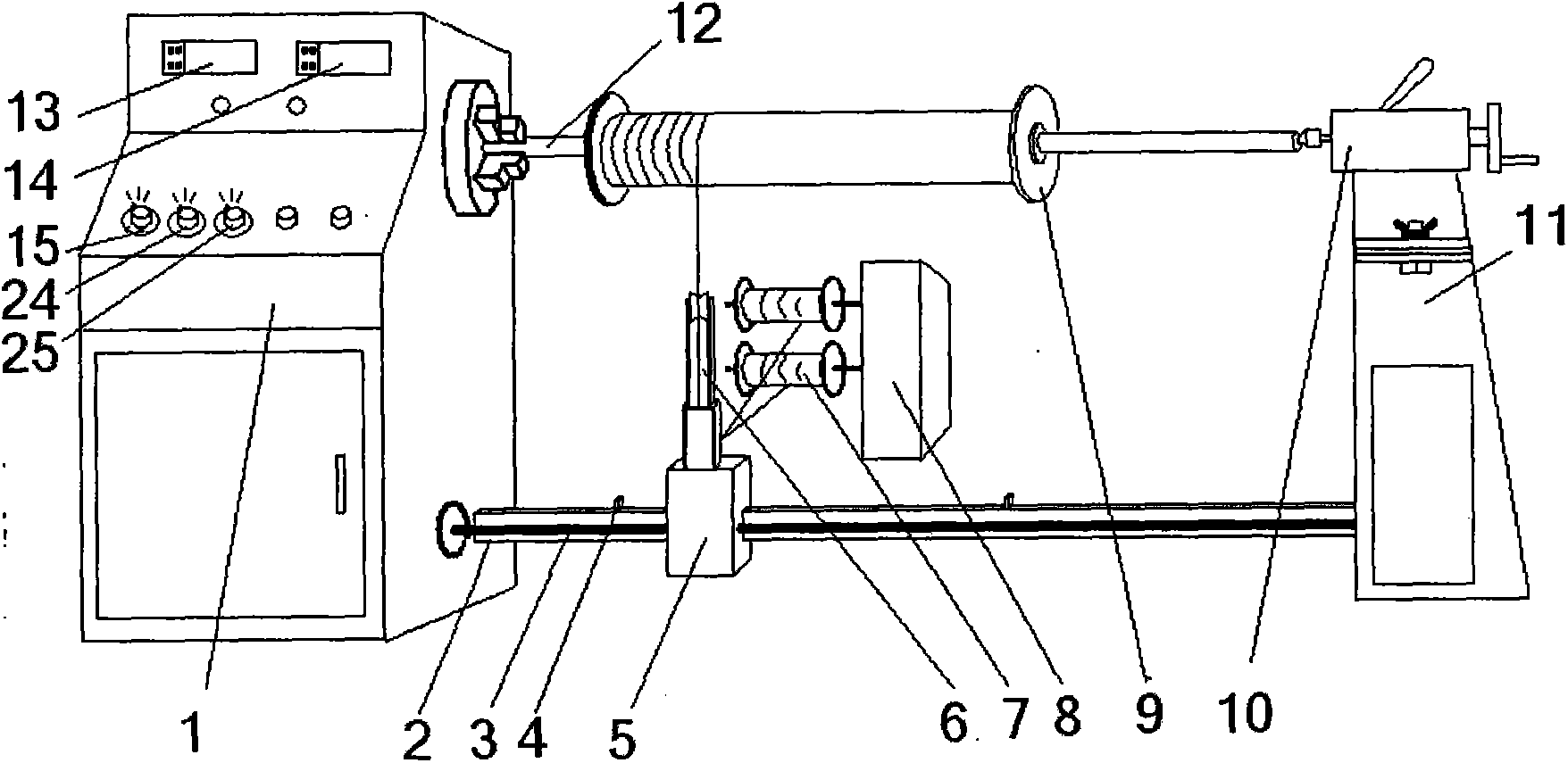

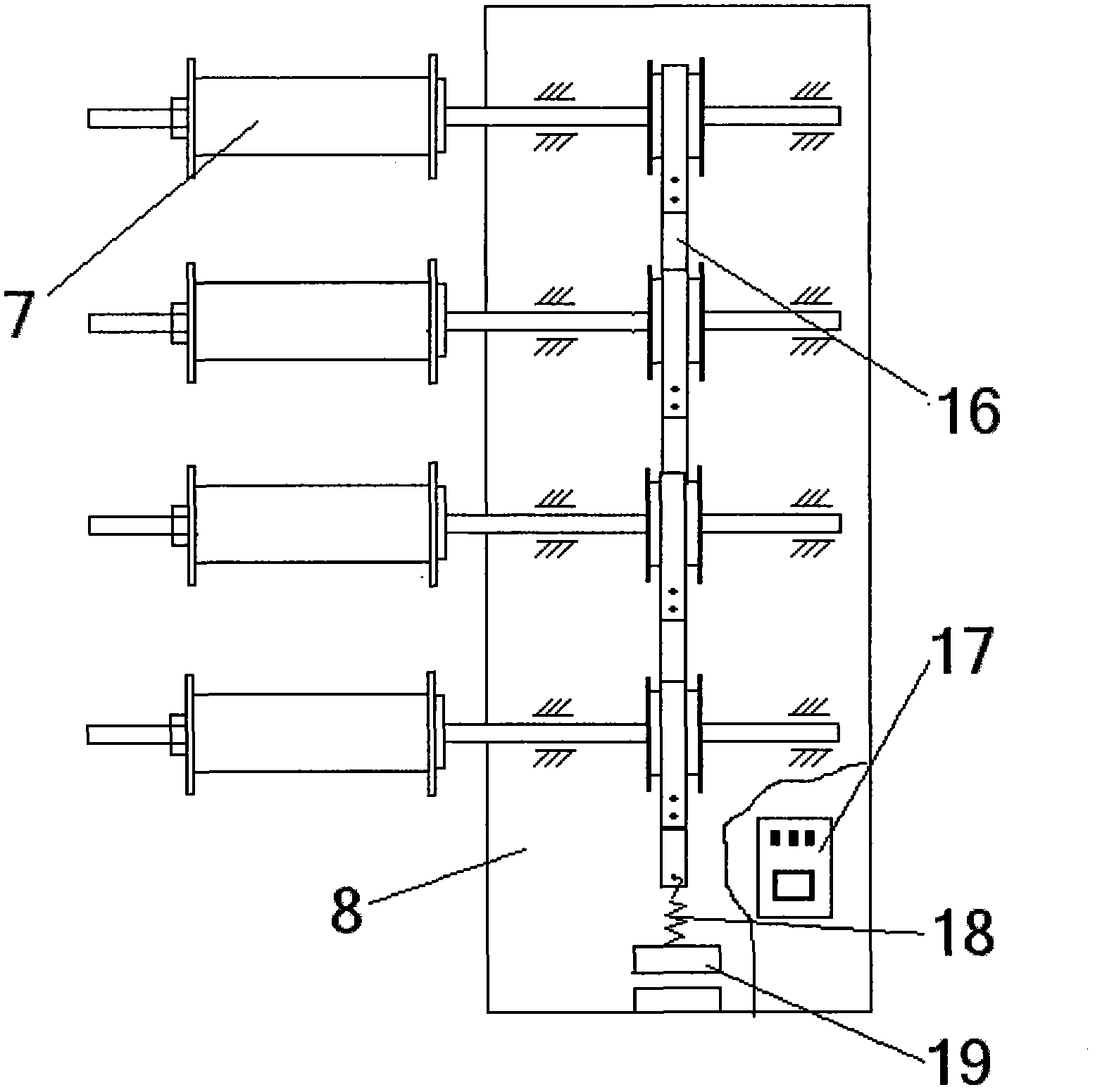

[0015] Further description will be made below in conjunction with the accompanying drawings. As shown in the attached figure, the multifunctional CNC winding machine includes a machine head, a tailstock, a winding rod, a pay-off mechanism and a wire arrangement mechanism. An electronic counting controller A13 and an electronic counting controller B14 are arranged on the head 1. The winding mold 9 is fixed on the winding rod 12, which can be a mold for winding a motor coil, or a mold for winding a transformer coil. The winding rod is driven by a winding motor 21, and the rotating speed of the winding motor is regulated by a winding frequency converter 20 through a knob 24. When winding the transformer coil, the top of the top seat 10 on the tail stock 11 withstands the tail end of the winding rod for its positioning. The top seat is hinged on the tail stock and fixed by bolts. Unfixed, the tailstock can be rotated horizontally to make room for loading and unloading the windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com