Method for designing structure of large-scale composite material reinforced wall plate

A technology of composite materials and design methods, applied in the directions of calculation, image data processing, special data processing applications, etc., can solve the problems of large secondary workload of the manufacturing side, large deviation of initial value from the true value, and inaccurate weight statistics, etc., to achieve Facilitate coordinated design, improve quality, and conceptual clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0022] The inventive method comprises the steps:

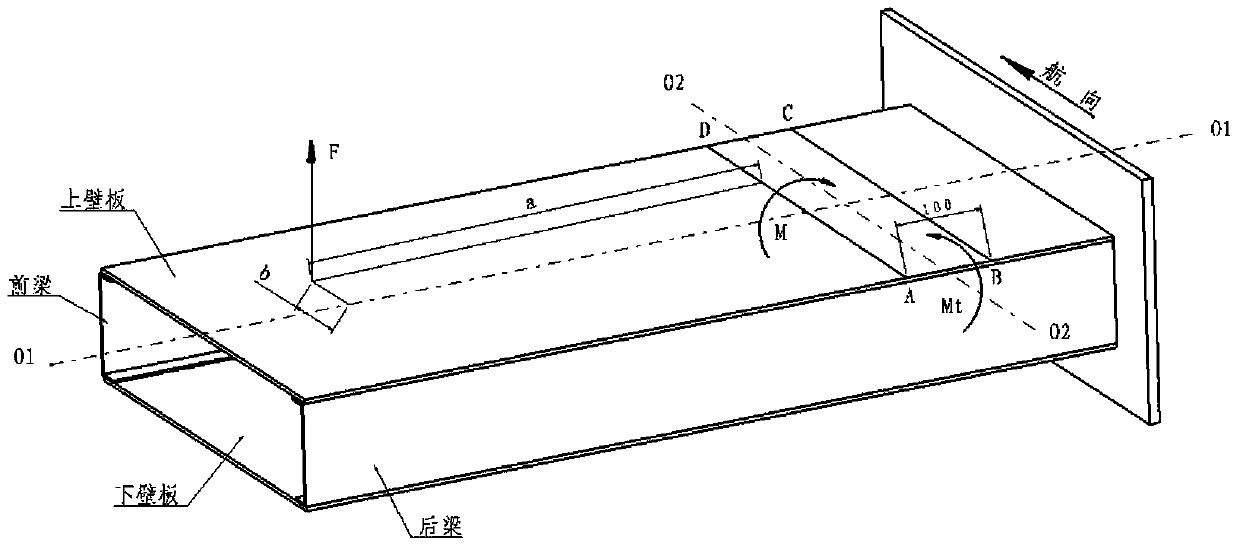

[0023] 1) The main box section of the empennage made of composite materials mainly includes the front beam, the rear beam, the upper wall panel, the lower wall panel and the ribs. The pressure F of the box section, the shape, the position of the front and rear beams and the selected composite materials are determined in the scheme design stage, and the single-block type Structural panels are subjected to large bending moments. For the convenience of calculation, the bearing of beam flanges on bending moments can be neglected at this time;

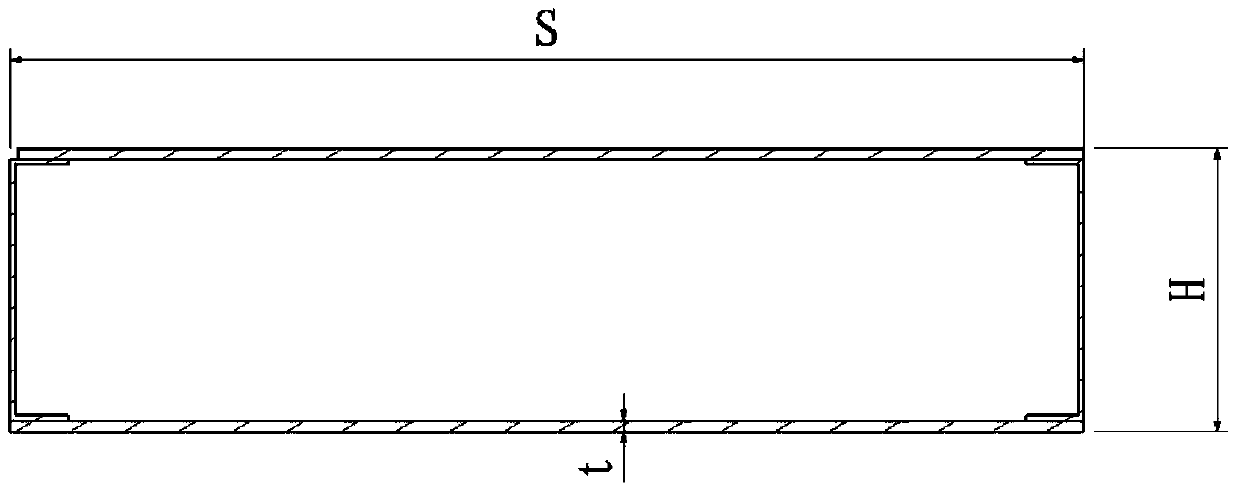

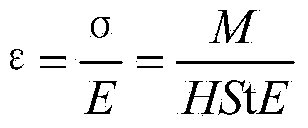

[0024] 2) Select the panel assessment area, the size of the area is selected according to the partition accuracy, and then the central axis of the area is taken to cut the panel, and the ply parameters to be determined in the obtained o1-o2 section represent the ply parameters of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com