Inflatable loading positioning device and loading positioning method of columns

A positioning device, an inflatable technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve problems such as easy to dump and difficult to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

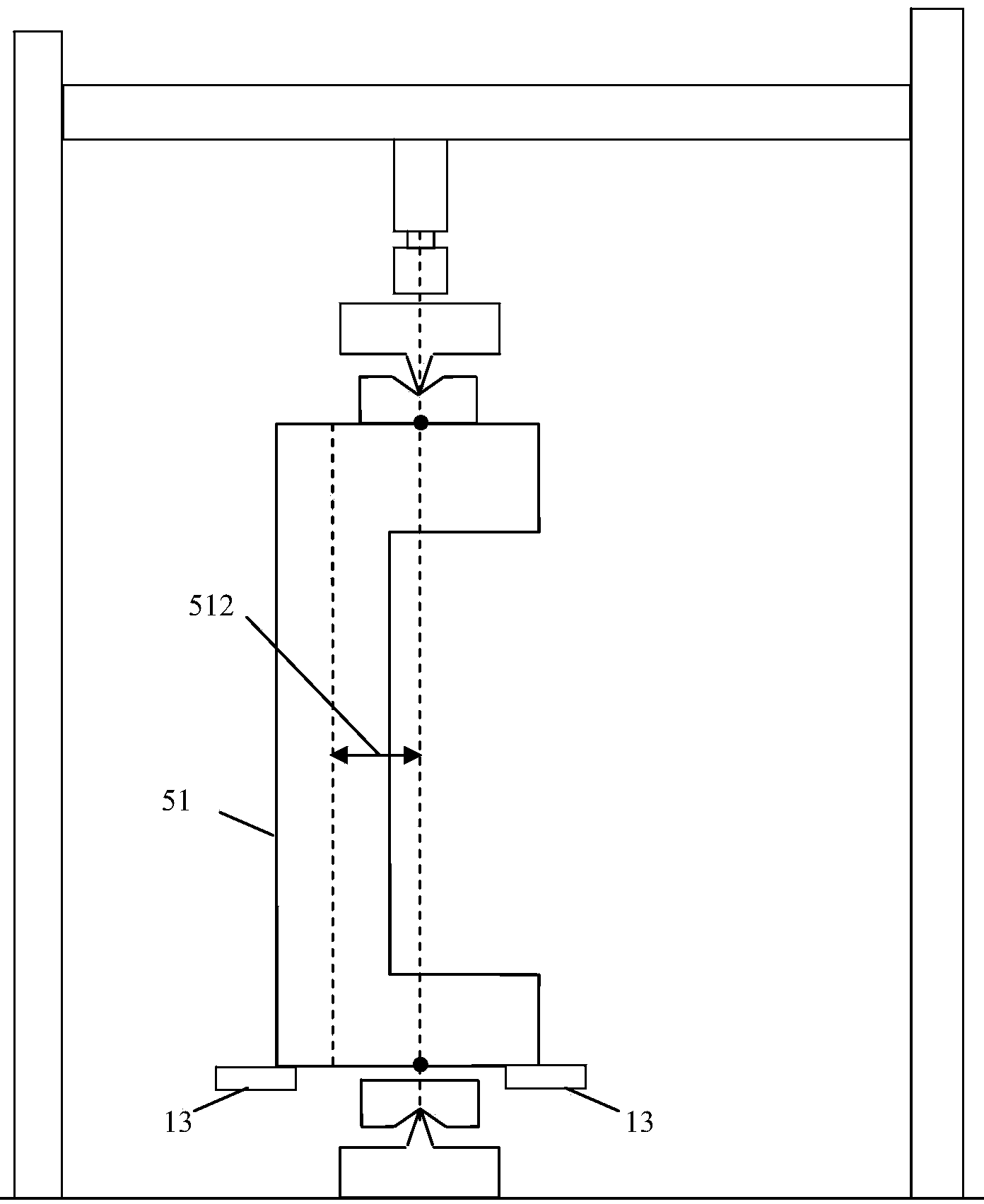

[0070] Embodiment 1: a loading test (see Figure 8 )

[0071] (1) A group of 4 reinforced concrete columns 51 with a cross-sectional size of 200×200mm, a height of 2200mm, and eccentricities 512 (the distance from the load acting position to the axis of the compressed column) are 0 mm, 20 mm, 40 mm, and 100 mm respectively. mm, C30 concrete, the main reinforcement of the column is 4 20, the stirrup is 6150, the protective layer is 15 mm, and the bearing capacity test is carried out on the column 51. The loading position of the column is the eccentricity 512, namely: 0 mm (at the axis), 20 mm, 40 mm, and 100 mm.

[0072] (2) Place the column 51 with an eccentricity of 100 mm to be subjected to the compression test on the positioning auxiliary frame;

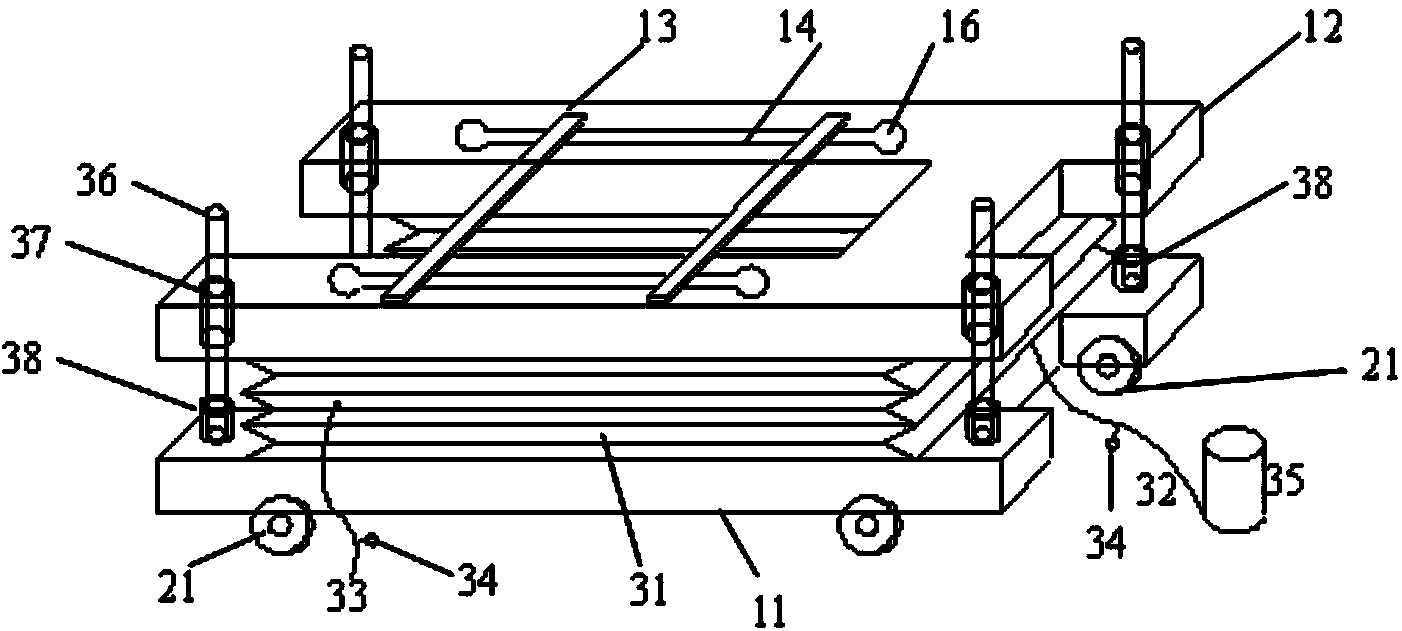

[0073] (3) Close the check valve on the air release pipe 33, inflate the inflator 35, and the air bag 31 rises to drive the "work" type upper floor 12 to move vertically upward along the vertical guide rod 36. When the suspen...

Embodiment 2

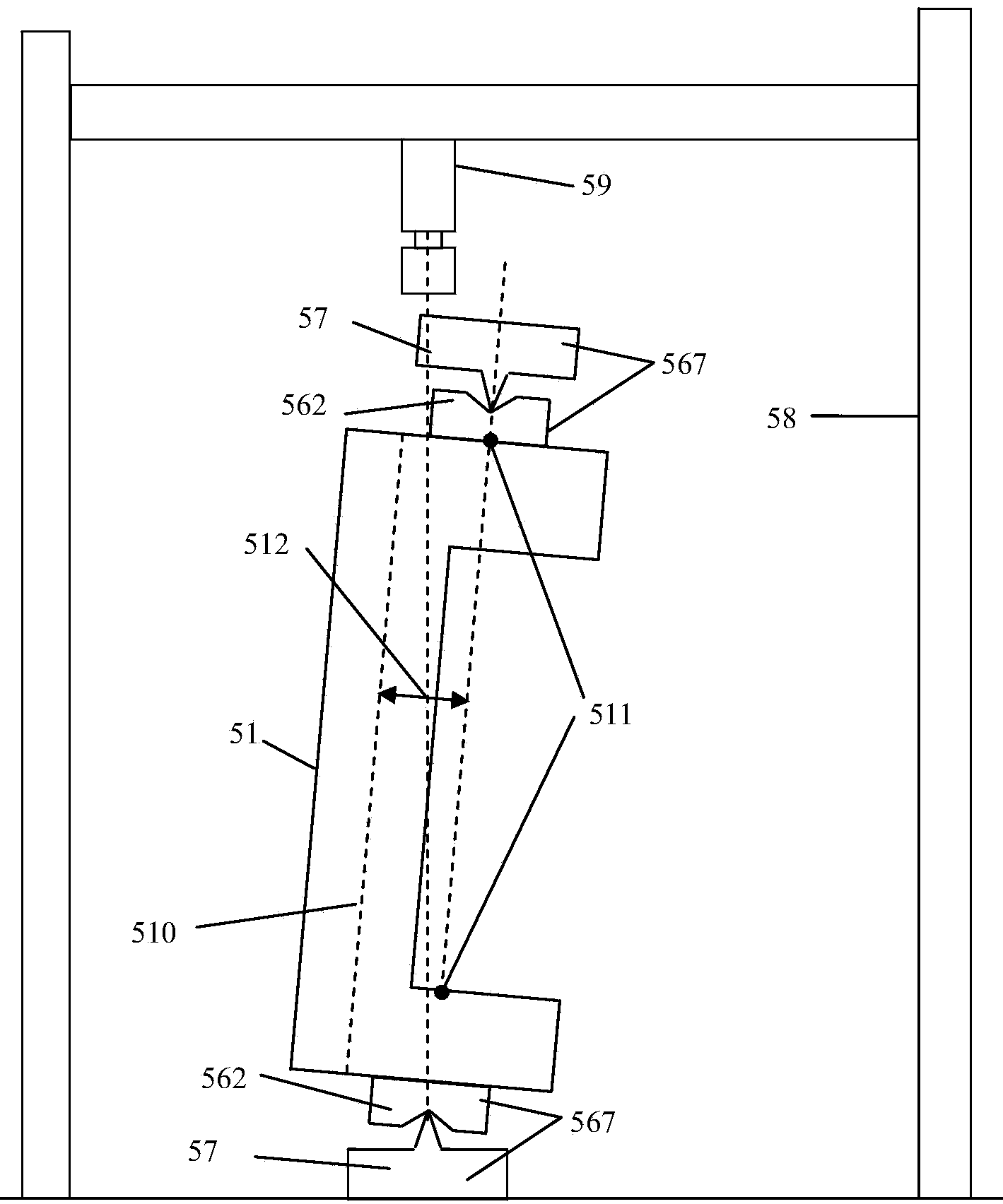

[0082] Embodiment 2: secondary loading test (see Figure 9 )

[0083] (1) Carry out residual bearing capacity test on column 51 under the coupled action of load and environment: the cross-sectional size of reinforced concrete column 51 is 120×120mm, the height is 750mm, and the main reinforcement of column 51 is 4 10, the stirrup is 650-100, the protective layer is 15 mm, the length of the protruding column of the flange is 120 mm, the eccentricity 512 is 100 mm, the diameter of the reserved hole 52 is 32 mm, the calculated ultimate bearing capacity of the column 51 is 64kN, and the diameter of the tension bar 53 is 25mm stainless finish rolling thread, the backing plate 54 has a diameter of 100mm and a thickness of 120mm, and the material is steel, and the diameter of the anchor bolt 55 is 55mm. The service load of kN, and the column 51 is placed in the artificial environment simulation box for 365 days to simulate the actual working state of the structure;

[0084] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com