Device with airflow drying, airflow screening and ultraviolet sterilization functions

A technology of ultraviolet sterilization and airflow drying, which is applied to lighting and heating equipment, separating solids from solids with airflow, and drying solid materials. It can solve the problems of easy-to-deposit materials, complex equipment structure, and low output. Good circulation, simple equipment structure and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0024] The first embodiment: a device with the functions of airflow drying, airflow screening and ultraviolet sterilization.

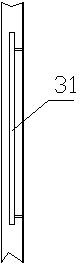

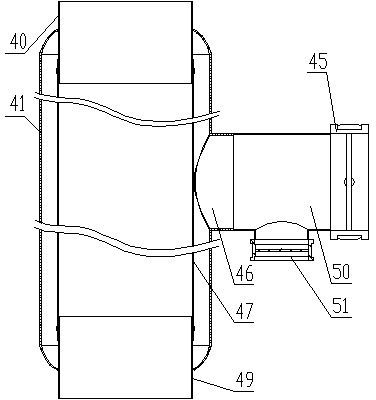

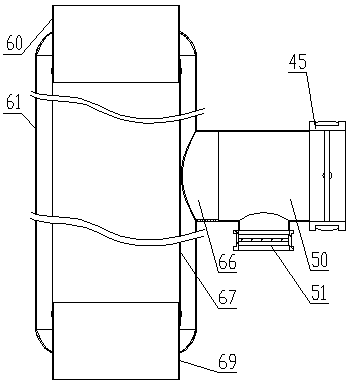

[0025] see Figure 1 to Figure 4 , the equipment with the functions of airflow drying, airflow screening and ultraviolet sterilization includes fan 1, circulation pipeline I2, dust collector 4, screen drum 10, regulating valve 5, air inlet tee 6, circulation pipeline II7, the above components According to fan 1 outlet, circulation pipeline I2, dust collector 4 inlet pipe 40, dust collector 4 ash discharge pipe 49, screen drum 10 inlet pipe 60, screen drum 10 outlet pipe 69, regulating valve 5, air intake tee 6, circulation The pipeline II7 and the inlet of the fan 1 are connected in sequence to form a circulation channel. An ultraviolet sterilizing lamp 31 is installed in the circulation pipeline I2. There is a discharge port on the circulation pipeline I2. A discharge valve 3 is installed on the discharge port. Another port of the tee 6 is an air inl...

no. 2 example

[0028] The second embodiment: another device with the functions of airflow drying, airflow screening and ultraviolet sterilization.

[0029] see Figure 5 to Figure 8 , the equipment with the functions of airflow drying, airflow screening and ultraviolet sterilization includes fan 1, circulation pipeline I2, dust collector 4, pipeline A22, dust collector 23, pipeline B24, sieve cylinder 11, sieve cylinder 10, regulating valve 5 , Intake Tee 6, Circulation Pipe II 7, Fan 25, Fan 26. The connection is different from that of Example 1 in that: one is that the pipeline A22, the dust collector 23, the pipeline B24, and the screen cylinder 11 connected in sequence are added between the dust discharge pipe of the dust collector 4 and the inlet pipe 60 of the screen cylinder 10; A fan 25 and a fan 26 connected in sequence are added between the circulation pipeline II7 and the fan inlet, and the rest are the same as those of the first embodiment.

[0030] The dust collector 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com