Multi-layer composite stainless steel tube

A stainless steel pipe and multi-layer composite technology, which is applied in the field of steel pipes, can solve the problems of long service life of stainless steel, low hardness of stainless steel, and easy wear and tear, and achieve good anti-corrosion and anti-wear effects, strong sealing, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

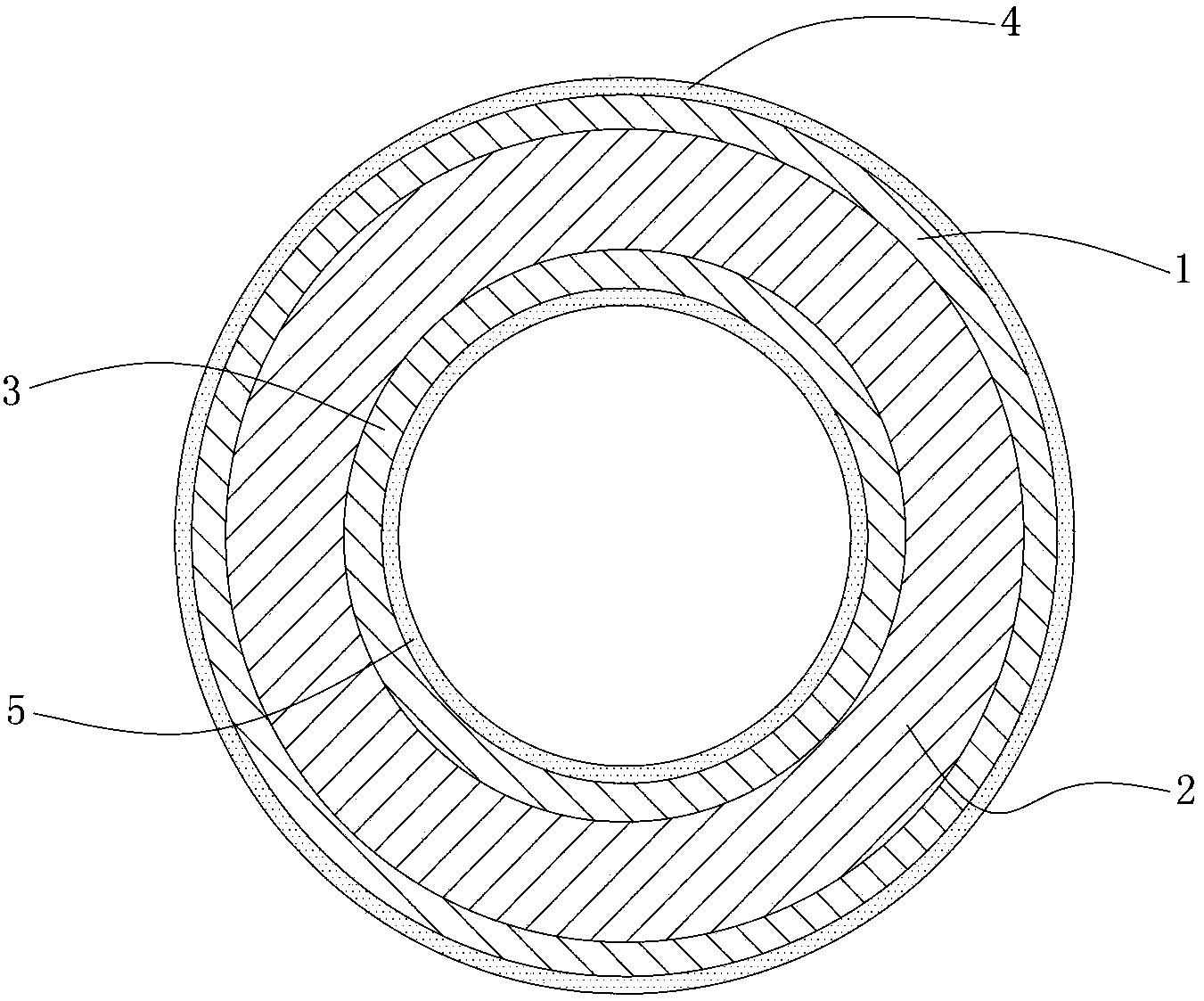

[0009] See figure 1 , the present invention has an outer tube body 1 and an inner tube body 3 made of stainless steel, and an intermediate layer 2 of plastic material fixed between the outer tube body 1 and the inner tube body 3; the outer tube body 1 A zirconium nitride layer 4 is coated on the outer wall of the inner pipe body 3; an anti-rust coating 5 is attached to the inner wall of the inner tube body 3; the thickness of the zirconium nitride layer 4 is 0.3-0.5mm; the anti-rust coating Layer 5 has a thickness of 0.1-2 mm.

[0010] The specific embodiments described above have further described the purpose, technical solutions and beneficial effects of the present invention in detail. It should be understood that the above descriptions are only specific embodiments of the present invention and are not intended to limit the present invention. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com