Five-link double-cam driving mechanism for tuck-in selvage bearded needle

A double-cam type and five-link technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of high processing cost, difficulty in ensuring precision, and large magnification, so as to reduce processing cost, improve motion accuracy, The effect of a small number of exercise pairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

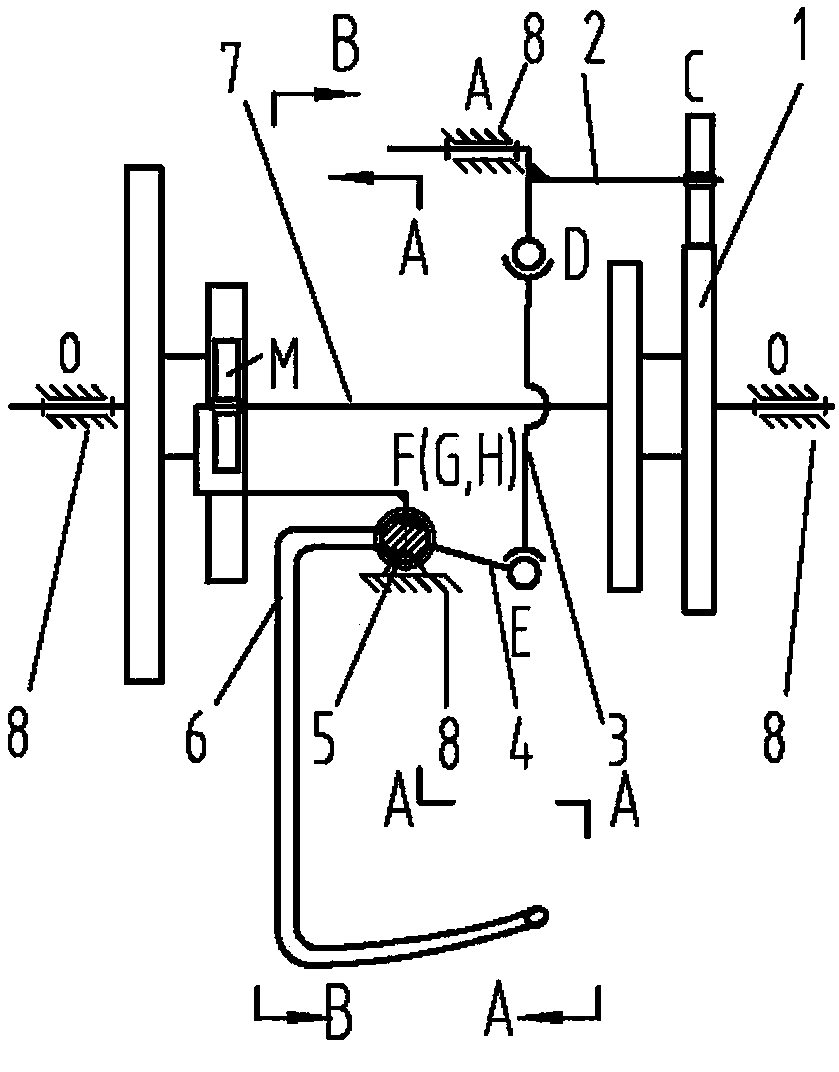

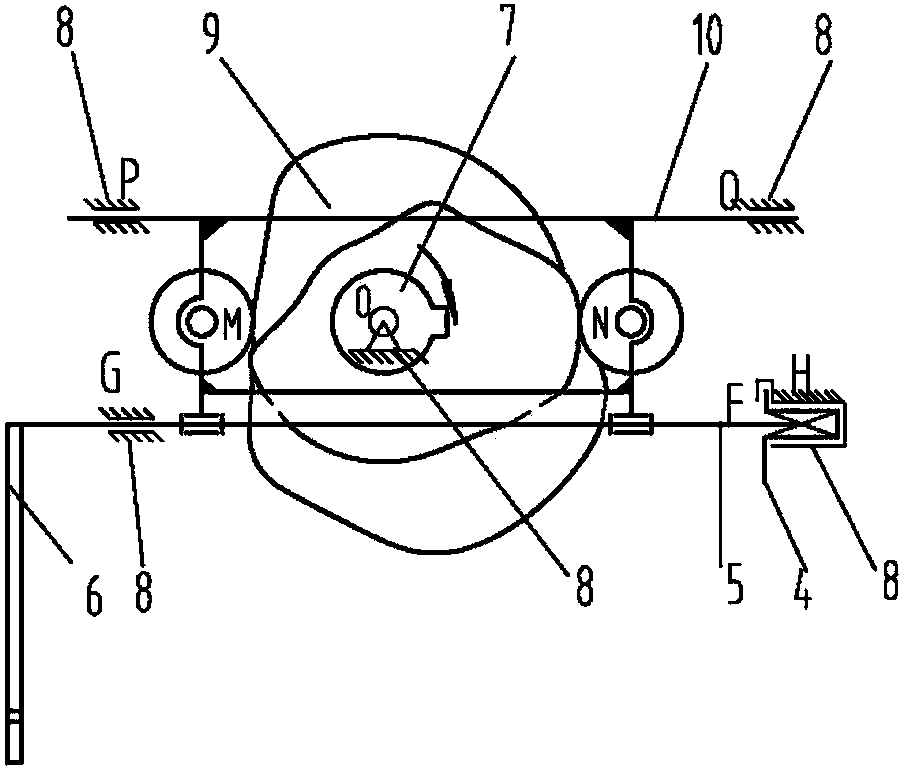

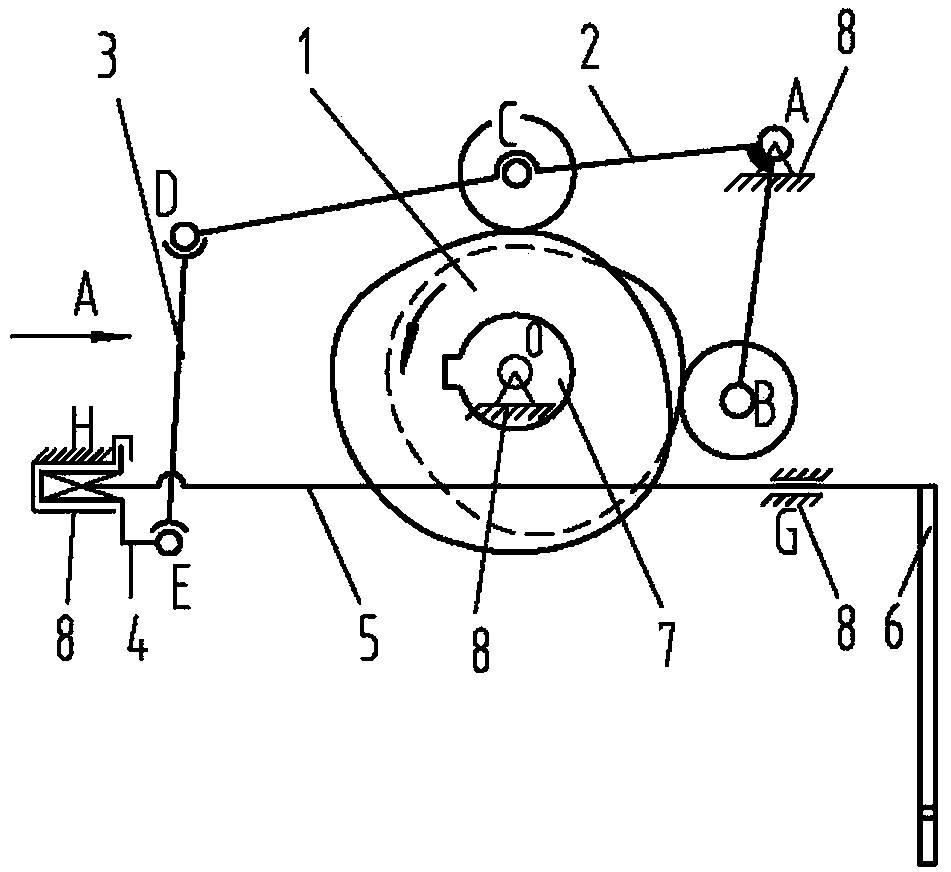

[0022] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 4 , 5 , 6, the present invention comprises a crochet rotating conjugate cam 101 fixedly connected on the camshaft 107 by a key; 1 , on which two rollers B which are respectively in contact with the hook rotation conjugate cam 101 are installed 1 and C 1 ;The crochet hook rotates the conjugate cam 101, the pendulum 102, and the roller B 1 、C 1 And the box body 108 constitutes a roller swing follower conjugate cam mechanism;

[0023] One end of the connecting rod 103 is hinged with the swing rod 102 through a spherical bearing to form a spherical pair D 1 , the other end is hinged with the crochet arm 104 through a spherical bearing to form a spherical pair E 1 , the crochet arm 104 is fixedly connected with the crochet telescopic shaft 105; the crochet telescopic shaft 105 and the box body 108 are connected by sliding bearings to form two left and right cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com