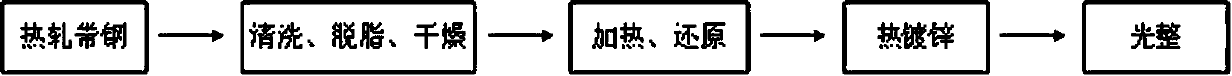

Hot rolled strip steel pickling-free hot galvanizing method based on scale reduction

A technology of hot-rolled strip steel and iron scale, applied in the field of metallurgy, can solve the problems of high surface roughness, low coiling temperature, and fast cooling speed of strip steel, and achieve the elimination of pickling process, elimination of exposed plating, and good adhesion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The composition of the hot-rolled steel strip used contains C 0.023%, Si 0.008%, Mn 0.15%, P 0.014%, S 0.015%, N 0.005%, Al 0.04%, Cu 0.006%, Cr 0.02%, Ni 0.003% by weight %, Ca 0.002%, Ti 0.001%, and the balance is Fe; the thickness of the hot-rolled strip steel is 1mm; Fe 3 o 4 / Fe and proeutectoid Fe 3 o 4 composition;

[0040] In the heating furnace, heat the hot-rolled strip steel at a rate of 15°C / s to 900°C for reduction annealing. During the reduction annealing, the atmosphere of the heating furnace is the coke oven gas atmosphere, and the combustion air excess coefficient is 0.93; after reduction annealing, the hot-rolled strip steel The volume fraction of FeO in the oxide scale structure is 90%, and the rest is Fe 3 o 4 Then the hot-rolled steel strip enters the reduction furnace, and is kept and reduced for 120s in a hydrogen atmosphere with a volume concentration of 10%; 20% of the iron oxide scale in the scale structure of the hot-rolled steel strip i...

Embodiment 2

[0045] The composition of the hot-rolled steel strip used contains C 0.005%, Si 0.009%, Mn 0.10%, P 0.011%, S 0.018%, N 0.002%, Al 0.14%, Cu 0.001%, Cr 0.005%, and the balance is Fe; the thickness of the hot-rolled strip steel is 2.5mm; the thickness of the scale on the surface of the hot-rolled strip steel is 8 μm, and the scale structure on the surface of the hot-rolled strip steel is composed of proeutectoid Fe 3 o 4 and eutectoid Fe 3 o 4 / Fe composition;

[0046] In the heating furnace, heat the hot-rolled strip steel at a rate of 20°C / s to 800°C for reduction annealing. During the reduction annealing, the atmosphere of the heating furnace is coke oven gas atmosphere, and the combustion air excess coefficient is 0.92; after reduction annealing, the hot-rolled strip steel The volume fraction of FeO in the oxide scale structure is 84%, and the rest is Fe 3 o 4 Then the hot-rolled steel strip enters the reduction furnace, and is kept and reduced for 200s in a hydrogen a...

Embodiment 3

[0051] The composition of the hot-rolled strip steel used contains C 0.05%, Si 0.005%, Mn 0.20%, P 0.010%, S 0.02%, N 0.001%, Al 0.06%, and the balance is Fe; The thickness is 2.4mm; the thickness of the oxide scale on the surface of the hot-rolled strip steel is 7μm, and the scale structure on the surface of the hot-rolled strip steel is composed of proeutectoid Fe 3 o 4 and eutectoid Fe 3 o 4 / Fe composition; and containing residual FeO with a volume fraction of 8%;

[0052] In the heating furnace, heat the hot-rolled strip steel at a rate of 20°C / s to 600°C for reduction annealing. During the reduction annealing, the atmosphere of the heating furnace is coke oven gas atmosphere, and the combustion air excess coefficient is 0.91; after reduction annealing, the hot-rolled strip steel The volume fraction of FeO in the oxide scale structure is 70%, and the rest is Fe 3 o 4 Then the hot-rolled steel strip enters the reduction furnace, and is kept and reduced for 180s in a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com