Process for producing low-chromium complex alloy grinding ball

A multi-component alloy and production process technology, applied in the field of wear-resistant materials, can solve problems such as poor fatigue impact resistance and wear resistance, high breakage rate and out-of-round rate, and low product yield, so as to improve internal and external quality, Improves fatigue impact resistance and wear resistance, and improves product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following will be described in detail in conjunction with the embodiments.

[0017] 1. Control of chemical composition

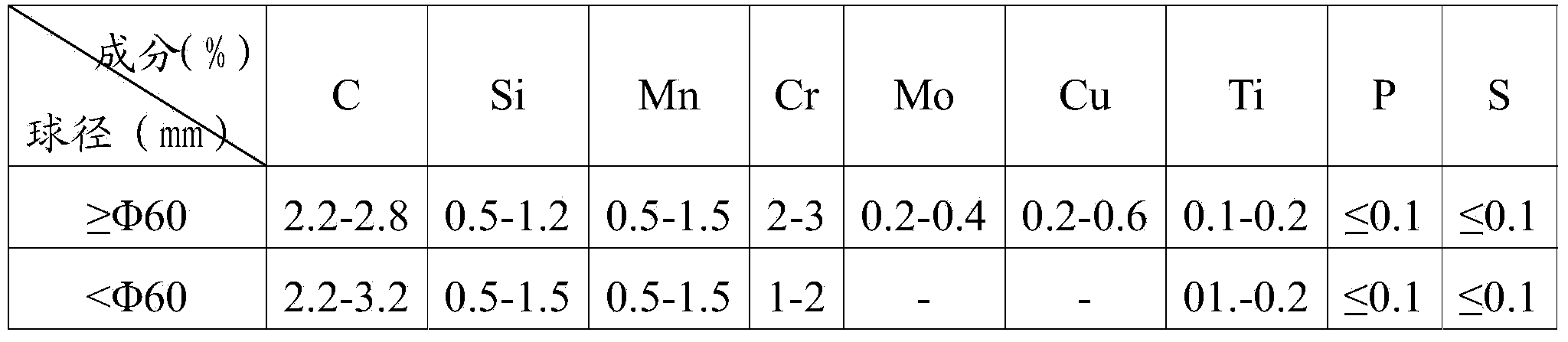

[0018] The chemical composition of the casting ball that technique of the present invention makes is as shown in table 1 below:

[0019] Table 1

[0020]

[0021] 2. Raw materials

[0022] Scrap steel: Clean scrap steel is required

[0023] Pig iron: use GB / T718-2005 foundry pig iron, the grade is Z14, and vanadium-titanium pig iron can also be used.

[0024] Carbon ferrochrome: use GB / T5683-2008 ferrochrome, the grade is FeCr600 or FeCr1000.

[0025] Ferromolybdenum: selected by GB / T3649-2008.

[0026] Rare earth ferrosilicon: use GB / T4173-2004 rare earth ferrosilicon alloy, the brand can be one of the following four types, FeSiRE21, FeSiRE24, FeSiRE27, FeSiRE230.

[0027] Ferrosilicon: reserve according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com