Thin-layer cement scale chemical cleaning agent mainly composed of hydroxyacetic acid

A technology of glycolic acid and its main components, applied in the field of chemical cleaning, can solve problems such as cleaning, damage to the surface of objects, and affect people's quality of life, and achieve the effect of overcoming erosion and damage, solving difficult processing, and achieving good cleaning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

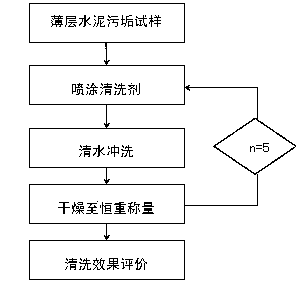

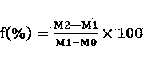

[0053] Example 1, a thin-layer cement dirt chemical cleaning agent with glycolic acid as the main component, water 100, glycolic acid 15, surfactant 1.0, corrosion inhibitor 1.0, penetrant 1.0, sodium tripolyphosphate scale inhibition Formulated with Agent 0.1 and Colorant 1.0. The 10 aforementioned cement dirt samples were treated with 5 cycles of spraying and washing, and the erosion rate and shedding rate were calculated. The test results are shown in Table 1.

Embodiment 2

[0054] Embodiment 2, a thin-layer cement dirt chemical cleaning agent with glycolic acid as the main component, press water 100, glycolic acid 40, surfactant 4.0, corrosion inhibitor 10.0, penetrant 4.0, sodium hexametaphosphate scale inhibition Formulated with Agent 1.0 and Colorant 5.0. The 10 aforementioned cement dirt samples were treated with 5 cycles of spraying and washing, and the erosion rate and shedding rate were calculated. The test results are shown in Table 1.

Embodiment 3

[0055] Example 3, a thin-layer cement dirt chemical cleaning agent with glycolic acid as the main component, water 100, glycolic acid 25, surfactant 3.0, corrosion inhibitor 4.0, penetrant 3.0, sodium tripolyphosphate scale inhibition Formulated with Agent 0.4 and Colorant 2.0. The 10 aforementioned cement dirt samples were treated with 5 cycles of spraying and washing, and the erosion rate and shedding rate were calculated. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com