Electric protective casing and preparation method thereof

A technology for sheathing tubes and electric power, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of acid-base microbial corrosion, poor tensile and flexural strength, easy deformation and fracture, and achieve low cost and good durability Salt heat and cold resistance, good tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of electrical sheath pipe, it is prepared from the following raw materials by weight:

[0020] Barium titanate powder 1, aluminum nitride powder 1, chromium carbide powder 1, borax 1, talcum powder 1, calcium carbonate powder 1, silica gel 1, decabromodiphenylethane 3, stearic acid 6, starch ether 8, carapace Prime 12, polycarbonate 18, hydroxyethyl cellulose 25, polyvinyl alcohol 32, polyvinyl chloride 40.

[0021] The particle diameter of above-mentioned barium titanate powder, aluminum nitride powder, chromium carbide powder, borax, talcum powder and calcium carbonate powder is controlled at 400 orders;

[0022] The pore volume of silica gel is 0.6-0.8ml / g, the average pore diameter is 5.0-7.0nm, and the specific surface is 500-650m 2 / g.

[0023] The preparation method of the above-mentioned electric power sheathing tube includes the following steps:

[0024] (1) Take the above-mentioned raw materials according to parts by weight for subsequent use;

[00...

Embodiment 2

[0029] A kind of electrical sheath pipe, it is prepared from the following raw materials by weight:

[0030] Barium titanate powder 2, aluminum nitride powder 2, chromium carbide powder 2, borax 2, talcum powder 2, calcium carbonate powder 2, silica gel 2, decabromodiphenylethane 5, stearic acid 8, starch ether 10, carapace Primer 15, polycarbonate 20, hydroxyethyl cellulose 30, polyvinyl alcohol 36, polyvinyl chloride 45.

[0031] Among them, the particle size of barium titanate powder, aluminum nitride powder, chromium carbide powder, borax, talcum powder and calcium carbonate powder is controlled at 500 mesh.

[0032] The preparation method of the above-mentioned electric power sheathing tube includes the following steps:

[0033] (1) Take the above-mentioned raw materials according to parts by weight for subsequent use;

[0034] (2) Put barium titanate powder, aluminum nitride powder, chromium carbide powder, borax, talcum powder and calcium carbonate powder into the mix...

Embodiment 3

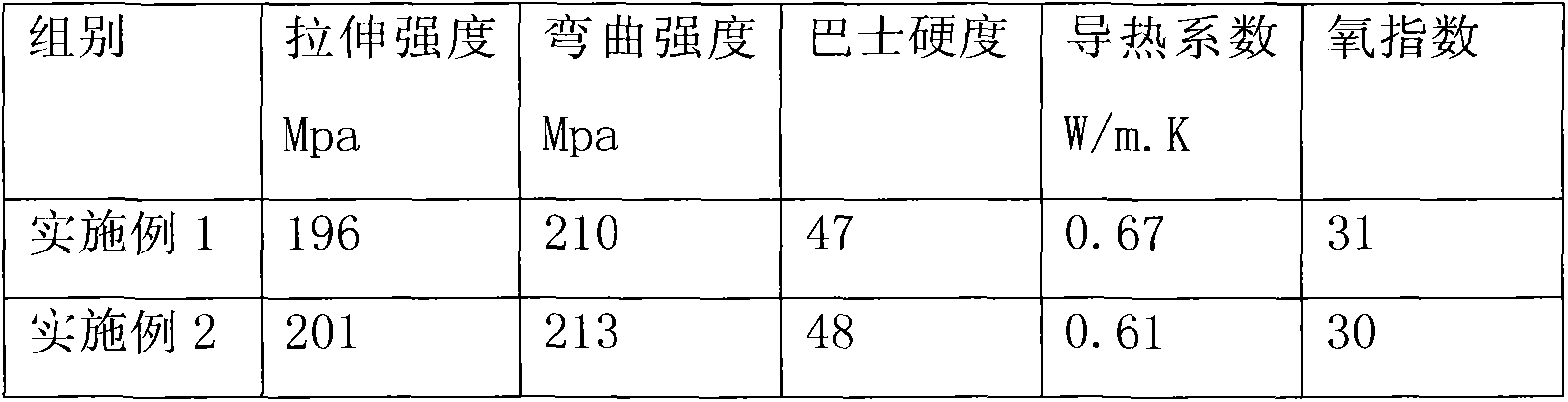

[0038] Measurement of various performance parameters of the electrical sheath pipe prepared by the present invention: the outer diameter is 100 mm, the wall thickness is 5 mm, and the length is 10 m as an example. Tensile strength, bending strength, bus hardness, thermal conductivity and oxygen index refer to GB / T1458, GB / T1449, GB / T3854, GB / T5990, GB / T8924 respectively. The specific results are shown in Table 1.

[0039] Table 1

[0040]

[0041] Salt resistance test: soak the electrical sheath pipe in 10% sodium chloride solution for 30 days, the tensile strength decreased by only 1%, the bending strength decreased by 3%, and the bus hardness decreased by 2%.

[0042] Heat resistance test: put the test sample into boiling water and boil for 1 hour, no deformation and foaming occurs, and more than 90% of tensile strength, bending strength and bus hardness remain, which has good heat resistance.

[0043] Cold resistance test: Put the test sample at -50°C for 60 days, no c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com