A kind of method of energy-saving refining acetate

The technology of an acetate and a rectifying tower is applied in the field of energy-saving and refined acetate, which can solve the problems of increasing the load of the reboiler at the bottom of the tower, reducing the separation efficiency of the rectifying tower, and increasing the energy consumption of the refining system, and achieves improvement. Separation efficiency, improving purity and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

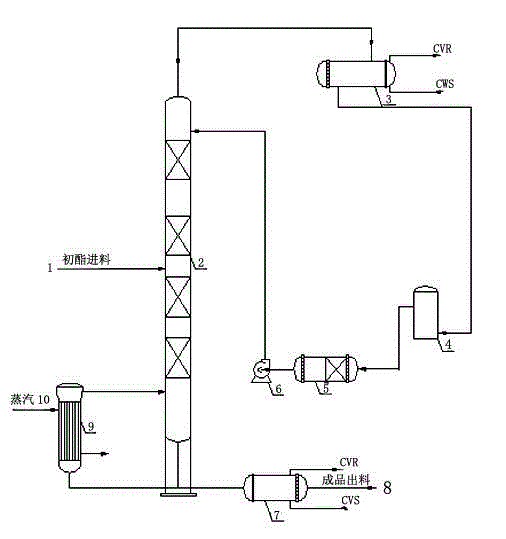

Embodiment 1

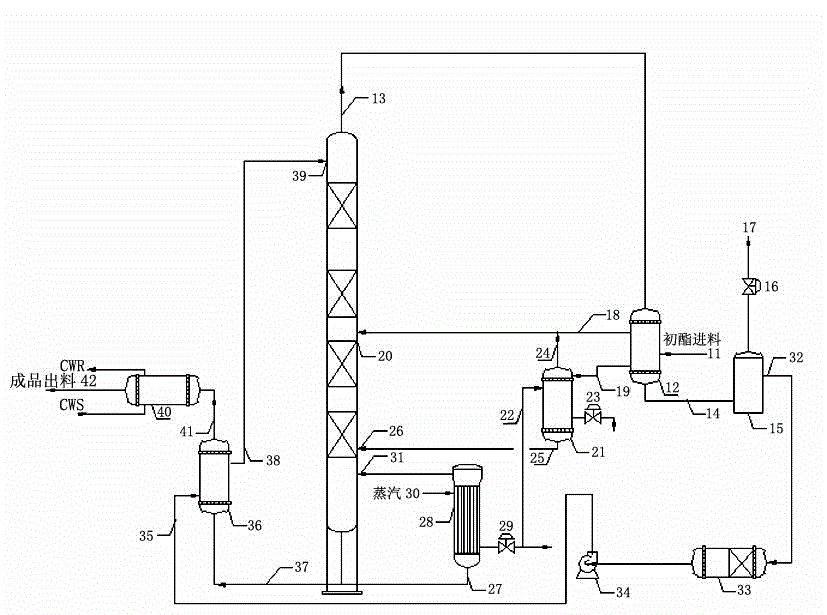

[0031] a) A pressure regulating valve 16 is set at the head oil tank top 15, so that the rectifying tower 20, the heat exchange pipeline, the head oil tank 15, and the return line are in a lower positive pressure state, so that the pressure at the top of the rectifying tower remains at In the range of 180-210kPa, the pressure at the bottom of the tower is kept in the range of 270-320kPa;

[0032] b) Let the gas phase stream 13 at the top of the tower and the ethyl acetate primary ester feed 11 from the ethyl ester water washing tower carry out heat exchange in the first heat exchanger 12, and the primary ester 18 that is partially vaporized enters the rectifying column 20 In the middle part, the partially condensed tower top material is then converted into head oil 14 and enters head oil tank 15, where some low-boiling components continue to form in the head oil tank 15 at a relatively high temperature of 106-110°C in the gas phase. form exists;

[0033] c) every 8 hours, ope...

Embodiment 2

[0041] a) A pressure regulating valve 16 is set at the head oil tank top 15, so that the rectifying tower 20, the heat exchange pipeline, the head oil tank 15, and the return line are in a lower positive pressure state, so that the pressure at the top of the rectifying tower remains at In the range of 200-230kPa, the pressure at the bottom of the tower is kept in the range of 300-340kPa;

[0042] b) Let the gaseous phase stream 13 at the top of the tower and the propyl acetate primary ester feed 11 from the esterification tower carry out heat exchange in the first heat exchanger 12, and the partially vaporized primary ester 18 enters the middle part of the rectifying tower 20 , the partially condensed tower overhead material is converted into head oil 14 and enters head oil tank 15, where some low-boiling components continue to form in the gas phase at a relatively high temperature of 113-117°C in head oil tank 15. exist;

[0043] c) every 8 hours, open the pressure regulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com