A kind of solid waste composite inorganic finishing mortar and preparation method thereof

A decorative mortar and inorganic technology, which is applied in the field of building wall decoration materials, can solve the problems of occupying precious urban land, difficult to handle and utilize, and pollute the environment, so as to reduce the phenomenon of efflorescence, reduce the environmental load, and improve the compactness of the mortar. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

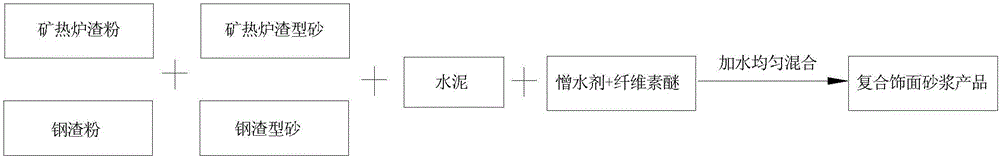

Method used

Image

Examples

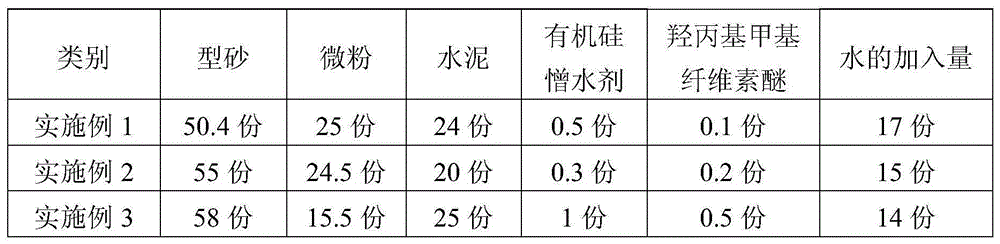

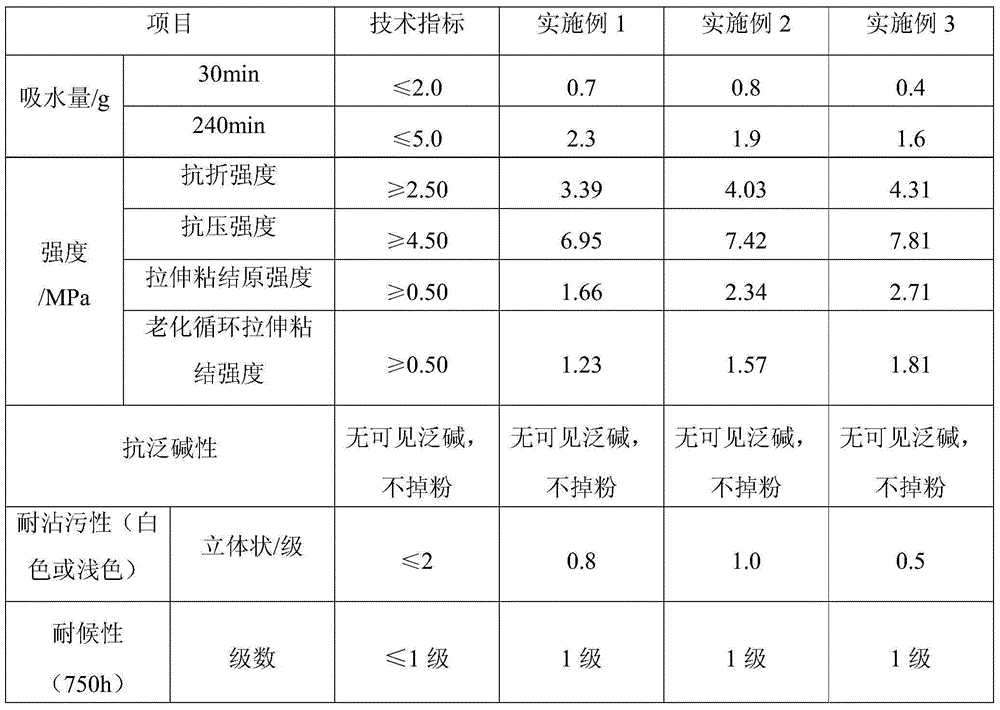

Embodiment 1

[0075] In parts by weight, take 50.4 parts of molding sand, 25 parts of micropowder, 24 parts of 42.5 grade high alumina cement, 0.5 part of 0202S silicone water repellent, and 0.1 part of MP-B40000 hydroxypropyl methyl cellulose ether. The specific data See Table 3. The specific specification parameters of submerged arc slag and steel slag in molding sand and micropowder are shown in the above-mentioned tables 1 and 2. Powder accounts for 50% and 50% by weight of micropowder respectively.

[0076] Put all raw material components except water in the mixer for dry material mixing, mix evenly, and then put the mixed material into a moisture-proof bag and seal it for later use.

[0077] During construction, the material is mixed with water by an electric mixer, and then applied to the wall surface by a spraying machine to form a building wall finish layer with a certain thickness, and the surface treatment is carried out. The addition of the water mixed with the material is 17%...

Embodiment 2

[0079] In parts by weight, take 55 parts of molding sand, 24.5 parts of micropowder, 20 parts of 42.5 grade high alumina cement, 0.3 parts of 0202S silicone water repellent, and 0.2 parts of MP-B40000 hydroxypropyl methyl cellulose ether. The specific data See Table 3. The specific specification parameters of submerged arc slag and steel slag in molding sand and micropowder are shown in the above-mentioned tables 1 and 2. Powder accounts for 50% and 50% by weight of micropowder respectively.

[0080] Put all raw material components except water in the mixer for dry material mixing, mix evenly, and then put the mixed material into a moisture-proof bag and seal it for later use.

[0081] During construction, the material is mixed with water by an electric mixer, and then applied to the wall surface by a spraying machine to form a building wall finish layer with a certain thickness, and the surface treatment is carried out. The addition of the water mixed with the material is 1...

Embodiment 3

[0083] In parts by weight, take 58 parts of molding sand, 15.5 parts of micropowder, 25 parts of 42.5 grade high alumina cement, 1 part of 0202S type silicone water repellent, and 0.5 parts of MP-B40000 type hydroxypropyl methylcellulose ether. The specific data See Table 3. The specific specification parameters of submerged arc slag and steel slag in molding sand and micropowder are shown in the above-mentioned tables 1 and 2. Powder accounts for 50% and 50% by weight of micropowder respectively.

[0084] Put all the original components except water into the mixer for dry material mixing, mix evenly, then put the mixed material into a moisture-proof bag and seal it for later use.

[0085] During construction, the material is mixed with water by an electric mixer, and then applied to the wall surface by a spraying machine to form a building wall finish layer with a certain thickness, and the surface treatment is carried out. The addition of the water mixed with the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com