Injection molding machine for two-material molding and control method thereof

An injection molding machine and dual-material technology, which is applied in the field of injection molding machines for dual-material molding and its control, can solve the problems of difficult rotation of the central shaft, difficult mold replacement, and adhesion of bearing parts, so as to avoid collisions and prevent mold damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

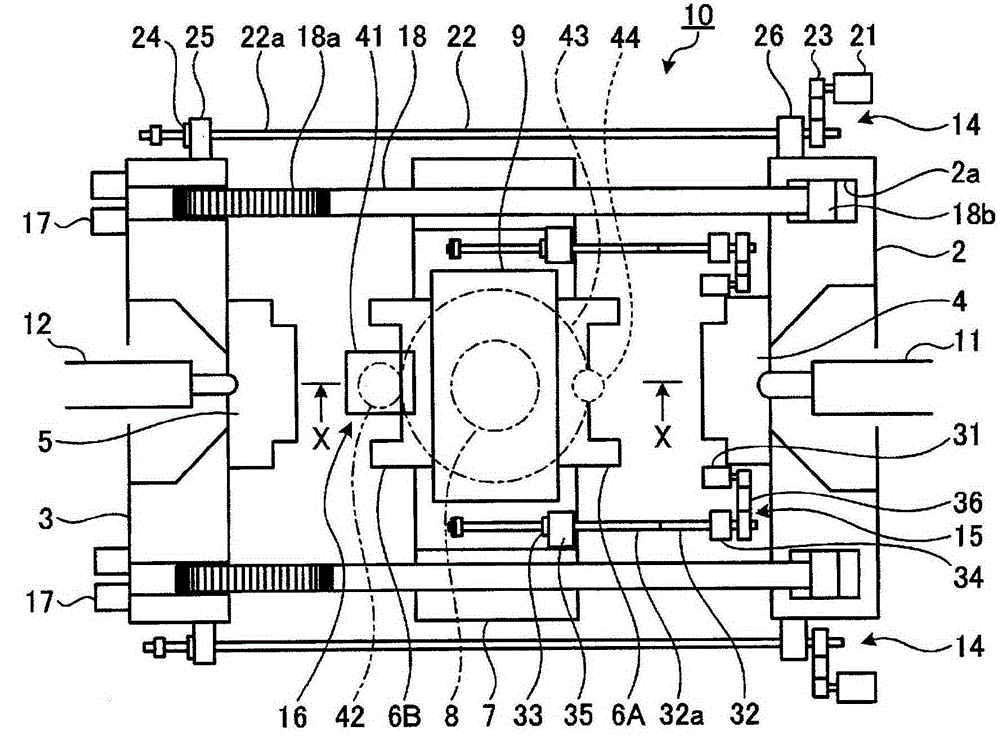

[0076] The injection molding machine for two-material molding of this embodiment has two cavities formed by a mold for a movable platen, a mold for a fixed platen, and a mold for both sides of a rotating platen disposed between the two platens. Different types of resins are injected separately, and the rotary platen is rotated 180 degrees to perform double injection, and the two materials are integrally molded. Among them, it is easy to drive the movement of the movable platen and the rotary platen, and the rotation of the rotary platen. Electric drive unit for control.

[0077] Next, a first embodiment will be described with reference to the drawings.

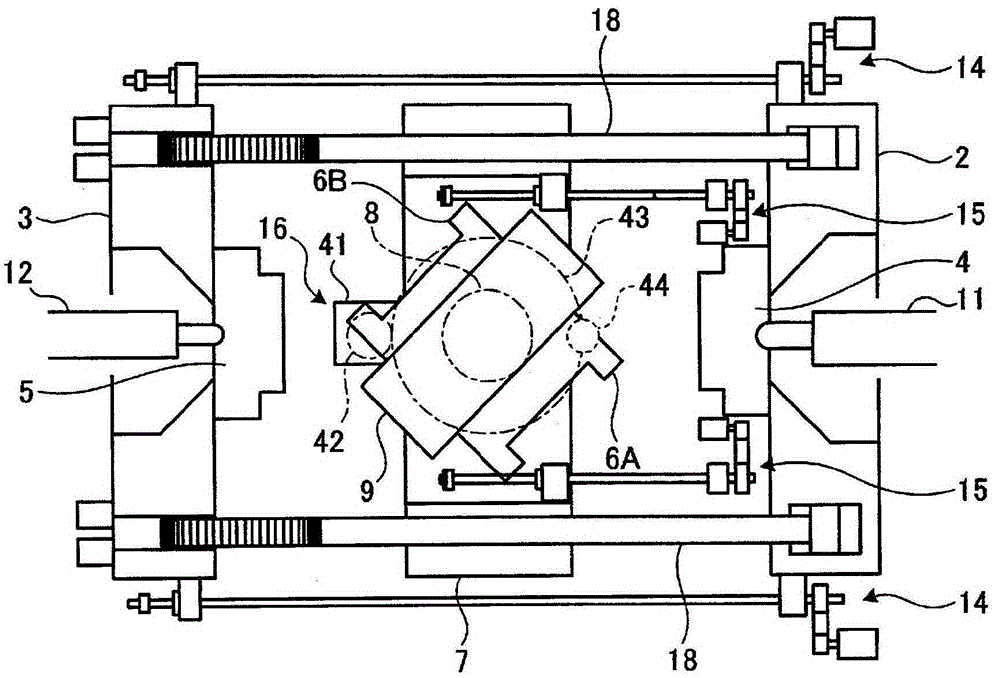

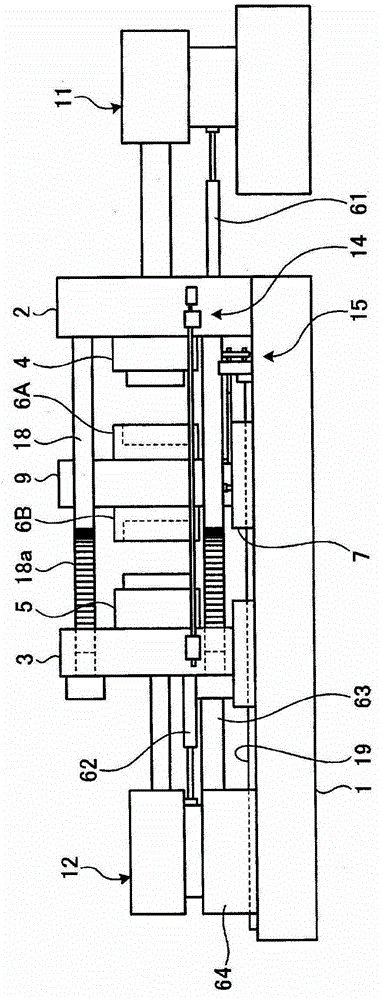

[0078] figure 1 It is a schematic plan view of the injection molding machine for two-material molding of the present invention. figure 2 yes means figure 1 A diagram of the rotation action of the rotary platen of the injection molding machine for bi-material molding. image 3 yes figure 1 Side view of an injection moldin...

no. 2 approach

[0132] Next, a second embodiment of the present invention will be described. This second embodiment differs from the first embodiment in that, as Figure 7 As shown in the schematic plan view of the injection molding machine 30 for bi-material molding, the servo motor A (21) and the ball wire are provided on the reversing table 7 to drive the movable die plate opening and closing unit 46 of the movable die plate 3. The support base 26 of the lever shaft 47 is the same as that of the first embodiment except for that, and therefore description of other structures will be omitted.

[0133] The advantage of the second embodiment is that the ball screw shaft 47 can be shortened, so the critical speed of the ball screw shaft 4 is increased, and the opening and closing speed of the movable platen 3 can be increased. In addition, since the ball screw is directly used to connect the rotating mounting plate 9 and the movable mounting plate 3, it is not necessary to detect and control t...

no. 3 approach

[0135] Next, a third embodiment of the present invention will be described. This second embodiment differs from the first embodiment in that, as Figure 8 As shown in the schematic side view of the rotary table, the rotary unit 50 is composed of a servo motor C (41) mounted on the reversing table 7, a pinion 53 mounted on the servo motor C (41), and a pinion 53 The meshing rotary mounting plate 9 is composed of a large gear 52 integrally provided and an endless toothed belt 54 wound around the pinion gear 53 and the large gear 52, and is a rotational drive that rotates the rotary mounting plate 9 in the forward and reverse directions for half a turn. The unit is the same as that of the first embodiment except for that, so descriptions of other structures are omitted.

[0136] According to this embodiment, its advantage is that it is not necessary to directly contact the large gear 52 and the small gear 53, and the distance between the rotation axis of the large gear 52 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com