Spiral duct machine support frame

A technology of spiral air duct and support frame, which is applied in the field of support frame devices, and can solve problems such as lack of vertical and horizontal movement adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

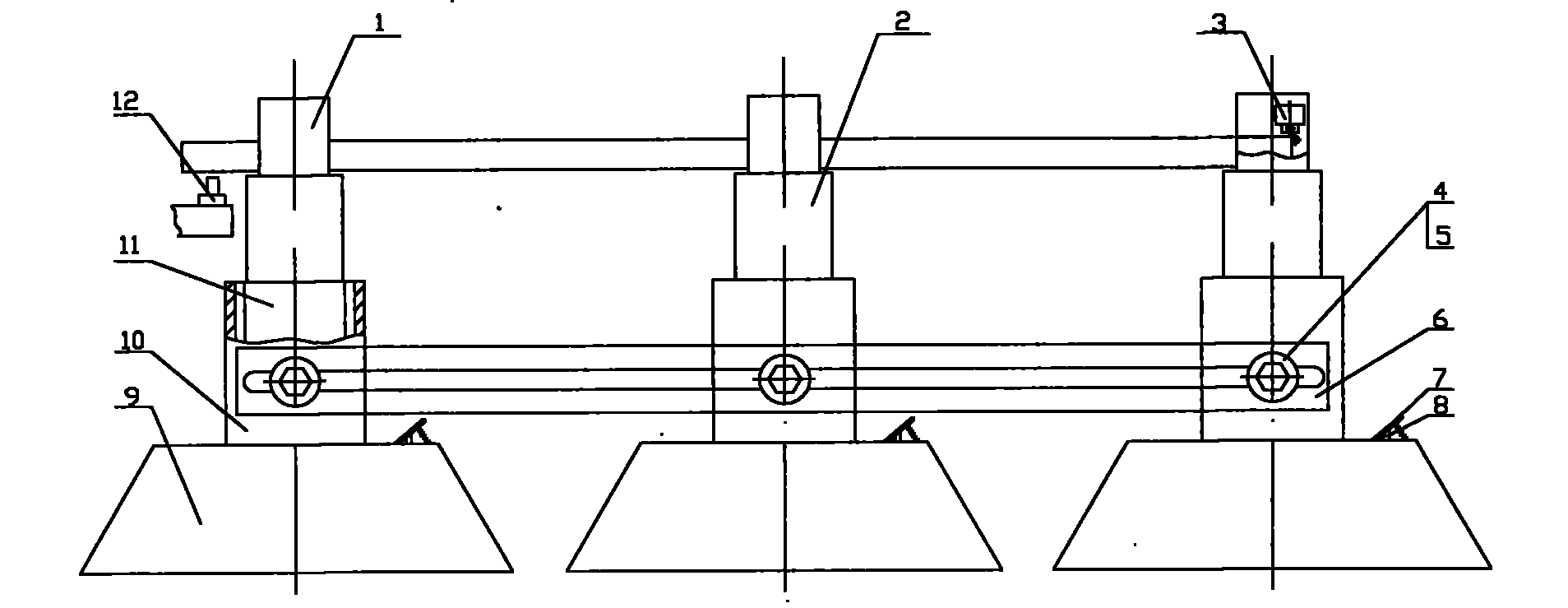

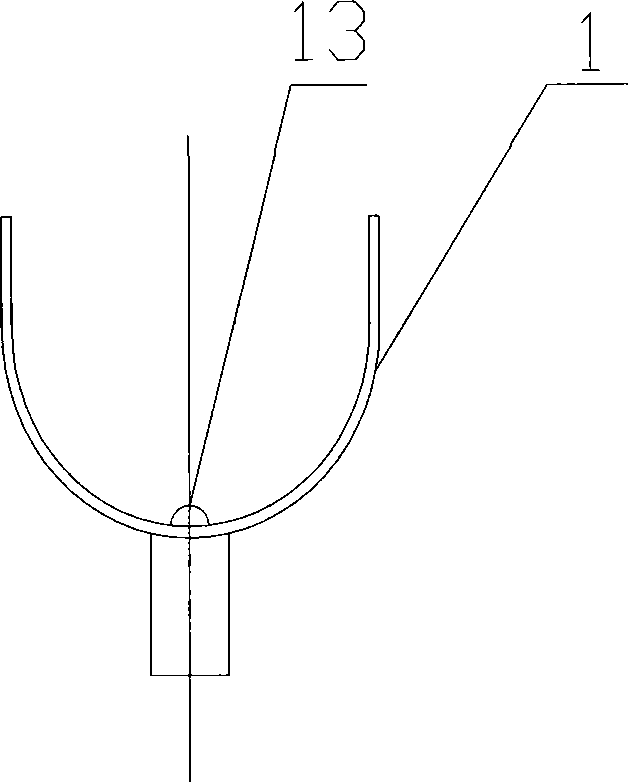

[0015] Attached below figure 1 , 2 And 3 and embodiment further illustrate the present invention.

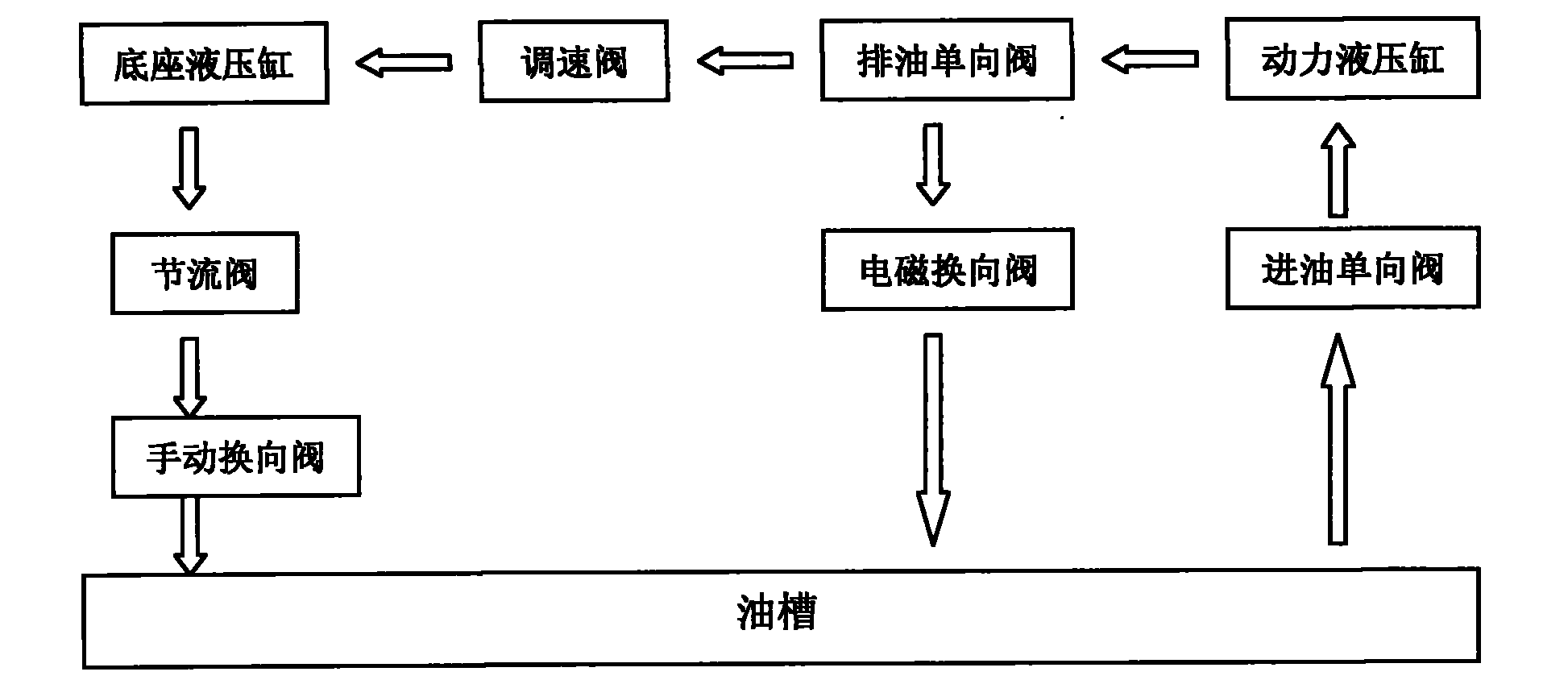

[0016] A support frame device for a spiral duct machine, which is mainly composed of a U-shaped frame 1, a lifting pipe 2, a base 9, a track steel 6, a pedal 7, a travel switch 3 and a cutting machine 12, and is characterized in that: the U-shaped frame 1 When rising, stepping on the pedal 7 on the upper surface edge of the base 9 drives the power part 8 of the hydraulic system in the base 9 to move up and down. At this time, the hydraulic oil enters the power hydraulic cylinder through the oil tank and the oil inlet check valve, and then passes through the oil discharge sheet The direction valve and speed regulating valve flow into the hydraulic cylinder of the base, and the hydraulic oil acts on the lower end of the lifting pipe 2. The lower end of the lifting pipe 2 and the sealing pipe 11 welded in the middle of the base 9 realize the piston movement, so that the lifting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com