Carbon aerogel for electric adsorption electrode and preparation method for carbon aerogel

A carbon airgel and electro-adsorption technology, applied in the direction of chemical instruments and methods, colloid chemistry, colloid chemistry, etc., can solve the problem of restricting the industrialization development and promotion of carbon aerogels, hindering the industrialization development of carbon aerogels, It is not conducive to the promotion and application of carbon aerogels, and achieves the effects of facilitating industrial development and popularization and application, promoting industrial development, and large pore volume and pore diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

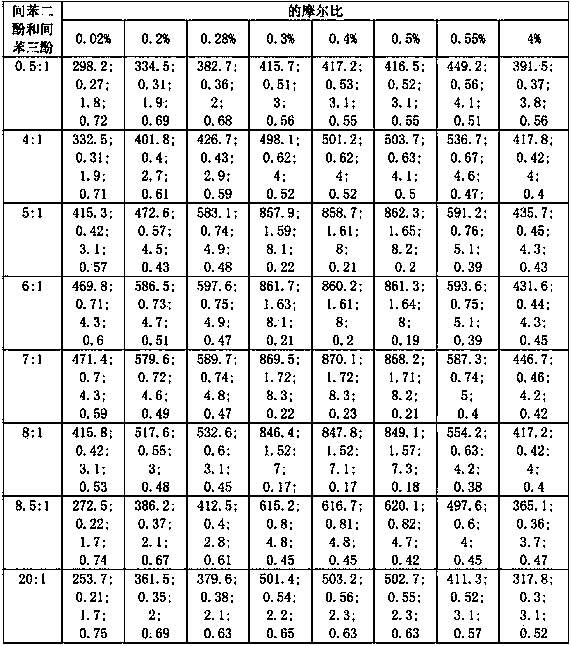

Embodiment 1

[0029] (1) Preparation of organic wet gel: mixing resorcinol and phloroglucinol with a molar ratio of 8:1, and then mixing the mixture of quinone and phloroglucinol with formaldehyde in a ratio of 1 according to the amount of substance :2 mixed, add deionized water and be mixed with the reaction liquid that mass fraction is 35%, then add the nickel acetate that the mol ratio with resorcinol and phloroglucinol mixture is 2000:1 and solute quality 0.3% , the reaction solution was mixed evenly by ultrasonic wave and then sealed, placed in a constant temperature water bath, and fully reacted at 50°C for 3 days to prepare nickel-loaded resorcinol-phloroglucinol-formaldehyde wet gel.

[0030] (2) Solvent replacement: The nickel-loaded resorcinol-phloroglucinol-formaldehyde wet gel prepared in step (1) was soaked in acetone solution for solvent replacement, and the acetone was replaced every 24 hours. Once, the water and other impurities in the wet gel are completely replaced.

[00...

Embodiment 2

[0035] (1) Preparation of organic wet gel: mixing resorcinol and phloroglucinol with a molar ratio of 5:1, and then

[0036] The mixture of hydroquinone and phloroglucinol is mixed with formaldehyde according to the ratio of the amount of substances of 1:2, and deionized water is added to prepare a reaction solution with a mass fraction of 45%, and then added with resorcinol and phloroglucinol Phenol is mixed with sodium carbonate with a molar ratio of 1000:1 and nickel acetate with a solute mass of 0.4%, and the reaction solution is mixed evenly by ultrasonic waves, sealed, placed in a constant temperature water bath, and fully reacted at 50°C for 3 days to obtain a loaded Resorcinol-phloroglucinol-formaldehyde wet gel of nickel.

[0037] (2) Solvent replacement: The nickel-loaded resorcinol-phloroglucinol-formaldehyde wet gel prepared in step (1) was soaked in acetone solution for solvent replacement, and the acetone was replaced every 24 hours. Once, the water and other im...

Embodiment 3

[0042] (1) Preparation of organic wet gel: mixing resorcinol and phloroglucinol with a molar ratio of 6:1, and then

[0043] The mixture of hydroquinone and phloroglucinol is mixed with formaldehyde according to the ratio of the amount of substances of 1:2, and deionized water is added to prepare a reaction solution with a mass fraction of 40%, and then added with resorcinol and phloroglucinol Phenol mixed with sodium carbonate with a molar ratio of 1500:1 and nickel acetate with a solute mass of 0.5%, mixed the reaction solution evenly with ultrasonic waves, sealed it, and placed it in a constant temperature water bath, and fully reacted at 50°C for 3 days to obtain a loaded Resorcinol-phloroglucinol-formaldehyde wet gel of nickel.

[0044] (2) Solvent replacement: soak the nickel-loaded resorcinol-phloroglucinol-formaldehyde wet gel prepared in step (1) in an acetone solution for solvent replacement, and replace the acetone every 24 hours, during which time 4 Once, the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore size distribution | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com