Printed circuit board with barrier dam protection layer

A printed circuit board and protective layer technology, applied in the direction of printed circuits connected with non-printed electrical components, can solve the problems of not being covered by green oil, drift, etc., and achieve high use value, stable performance, and no device drift. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

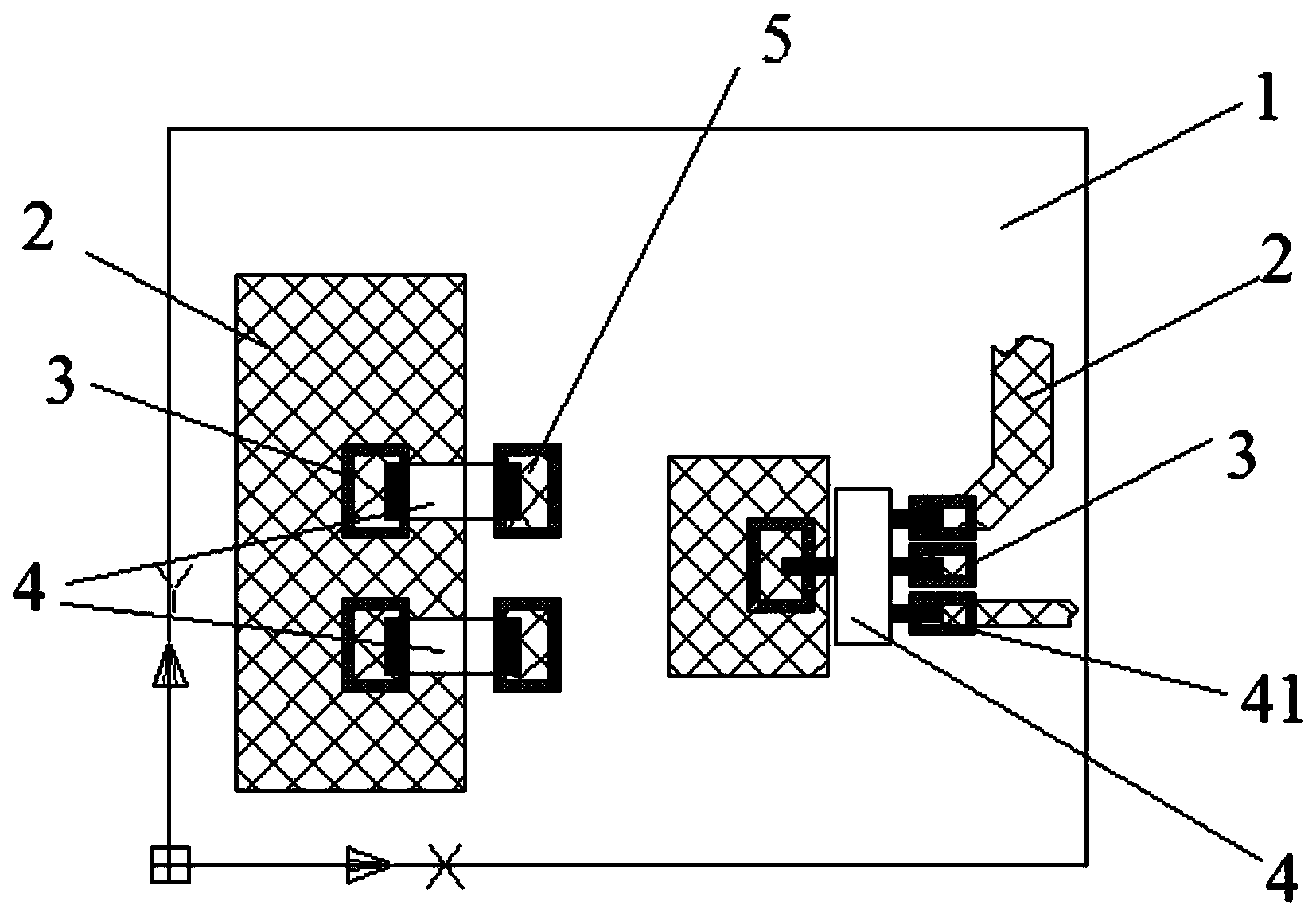

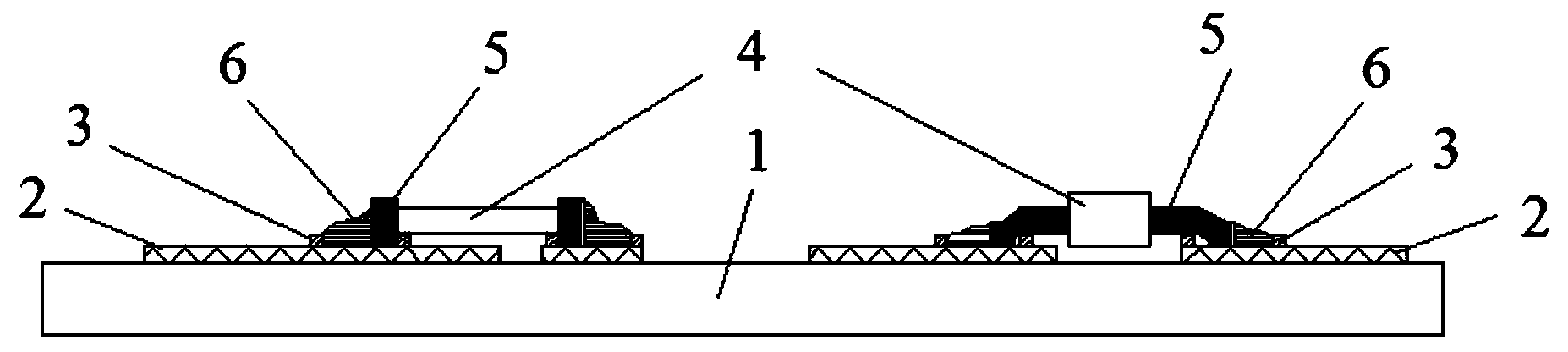

[0018] Such as figure 1 and 2 As shown, a printed circuit board with a dam protection layer includes a substrate 1, a circuit copper foil 2, a pad 5, a dam 3 and a device 4, and the circuit copper foil 2 is fixed on the substrate 1, and the The pad 5 and the dam 3 are respectively fixed on the line copper foil 2, the device 4 is welded on the pad 5 by soldering the device pin 41, the pad 5 is surrounded by the dam 3, and the Solder 6 packs inside.

[0019] The dam is a rectangular frame with the same area as the pad and a frame width of 0.2. Described dam is green oil dam or silk screen printing ink dam.

[0020] The process flow of the printed circuit board of the present invention is: single-sided copper clad board-cutting-photochemical method / screen printing image transfer-removal of anti-corrosion printing material-cleaning-drying-hole processing-shape processing-cleaning and drying - Curing - Rinsing and Drying - Pre-Fluxed - Drying - Finished Product.

[0021] The C...

Embodiment 2

[0023] The frame width is 0.5mm. Others are the same as embodiment 1.

Embodiment 3

[0025] The frame width is 1.0mm. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com