Drive circuit for high-power LED light source

A technology of LED light source and driving circuit, which is applied in the direction of light source, electric light source, electric lamp circuit layout, etc., can solve the problems of poor reliability, high cost, and large electromagnetic interference, and achieve the effect of cost reduction, high reliability, and good EMI performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

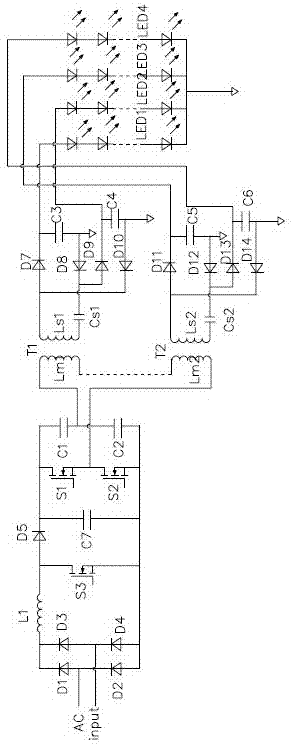

[0025] Combine below figure 2 The present invention will be further described with specific embodiments.

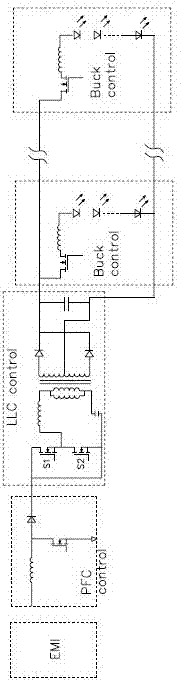

[0026] A drive circuit for high-power LED light sources, as attached figure 2 As shown, it includes a PFC circuit, and also includes a multi-string transformer LLC conversion circuit, and the multi-string transformer LLC conversion circuit is connected with the PFC circuit for constant current driving of the LED array.

[0027] The multi-string transformer LLC conversion circuit includes an isolated half-bridge composed of a first switch tube S1, a second switch tube S2, a first capacitor C1, and a second capacitor C2, and two identical isolation transformers T1 and T2. The primary sides of the first transformer T1 and the second transformer T2 are connected in series and connected to both ends of the diagonal line of the isolated half-bridge. After the secondary side of the first transformer T1 is connected in series with the eighth capacitor Cs1, the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com