An Electromagnetic Relay with Contact Bias Placement

A technology of electromagnetic relays and contacts, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of shortening the operating life of the motion mechanism, affecting the electrical performance of the relay, and affecting the stability of the motion, so as to improve the electrical performance index , to ensure stability, to avoid the effect of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

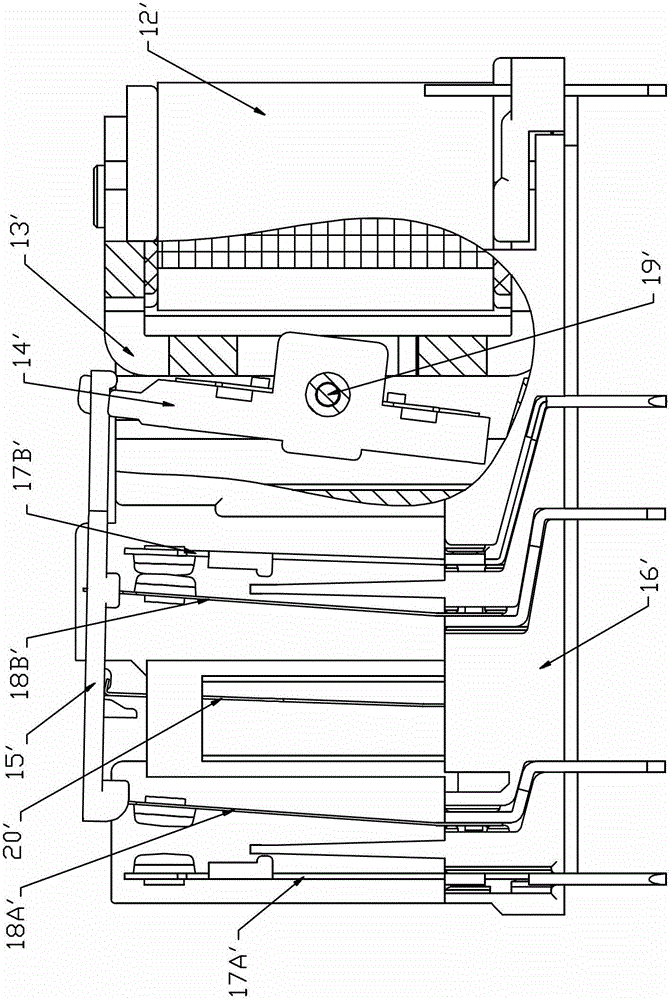

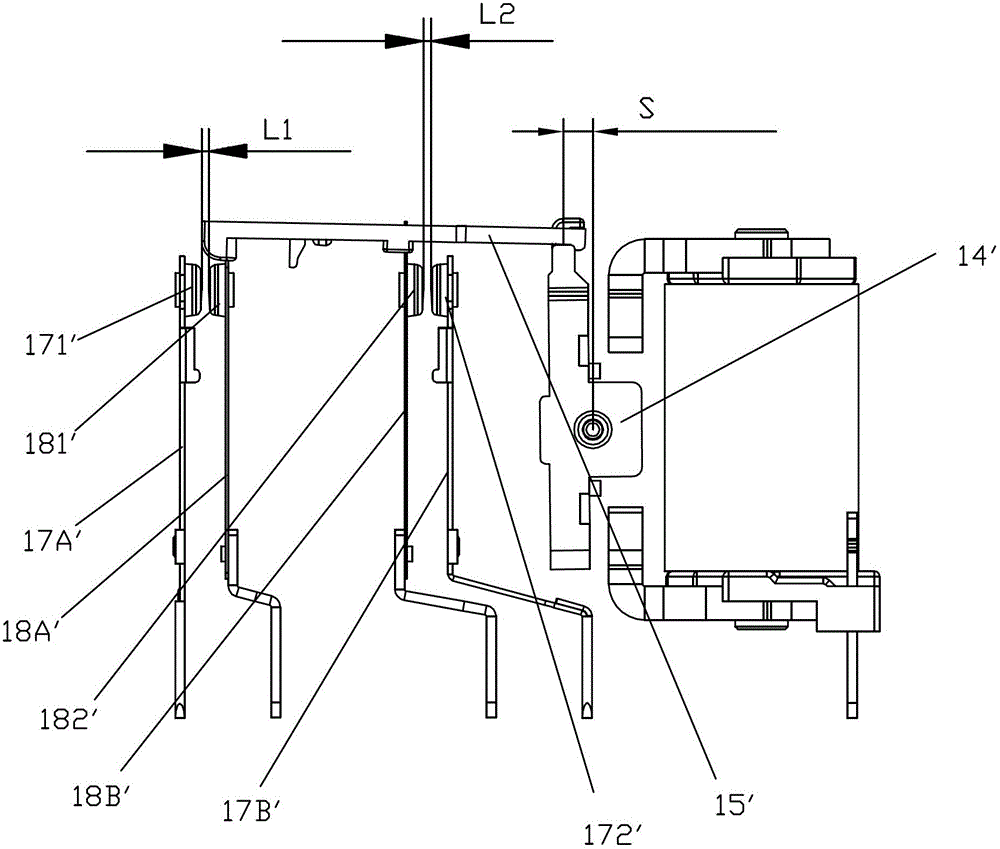

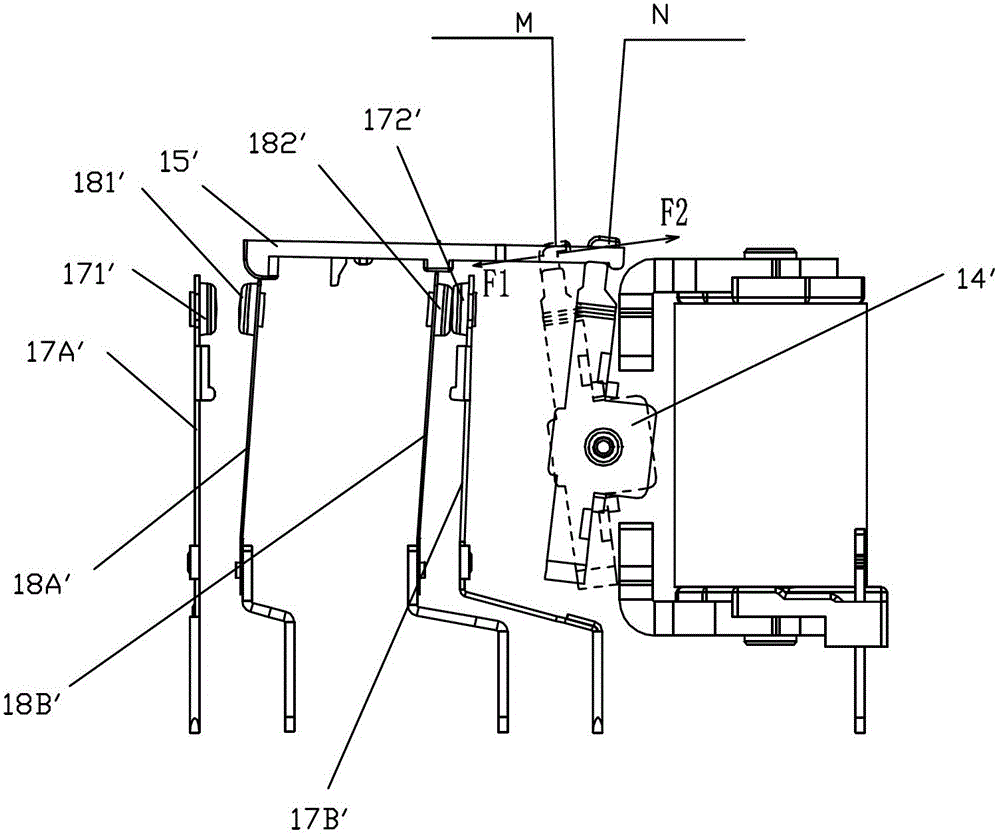

[0054] Examples, see Figure 3 to Figure 15 As shown, an electromagnetic relay with biased contacts of the present invention includes a magnetic circuit part 1, a base 21, a static spring assembly and a push card part 3; the magnetic circuit part 1 includes a coil 11, a yoke 12 and an armature part 13 , wherein the armature part is provided with a central rotating shaft 131 that can make it rotate, and the armature part 13 is rotatably positioned on the base 21 through the central rotating shaft 131 provided on the armature part, and of course it can also be positioned on other supportable bodies The static spring combination includes a normally open static spring combination 22 and a normally closed static spring combination 23, and the normally open static spring combination 22 is composed of a normally open static spring sheet 221 and a normally open static contact 222 fixed on the normally open static spring sheet The normally closed static spring combination 23 is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com