Method and system for evaluating creep damage of high temperature component

A technology for high-temperature components and evaluation methods, which is applied in the testing of machine/structural components, testing the ductility of materials, testing metals, etc. It can solve problems such as difficult tests, changes, damage development curves, etc., to optimize replacement and reduce economical costs. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

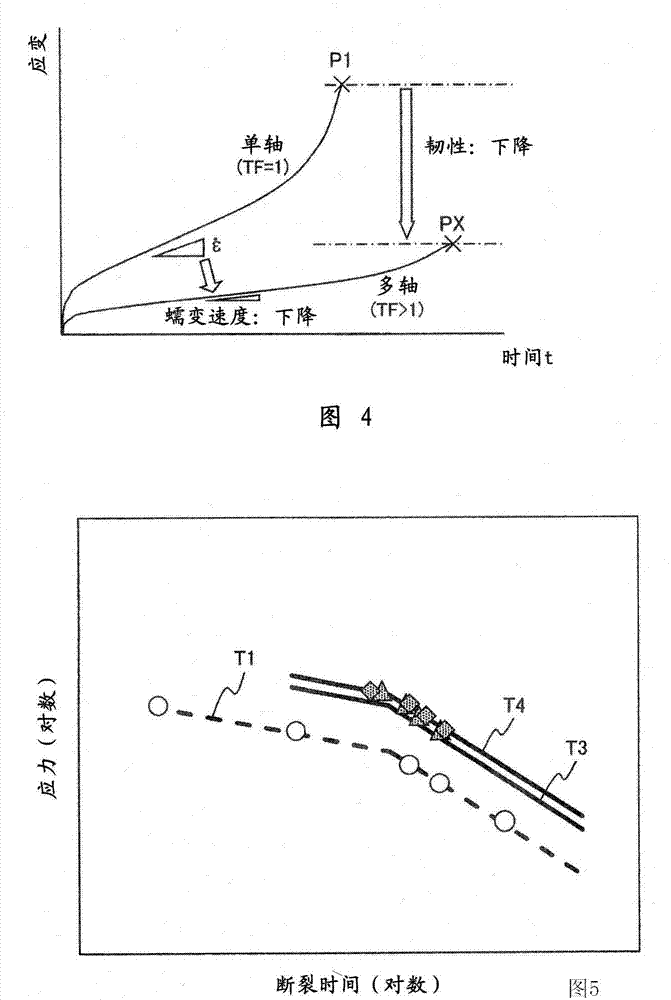

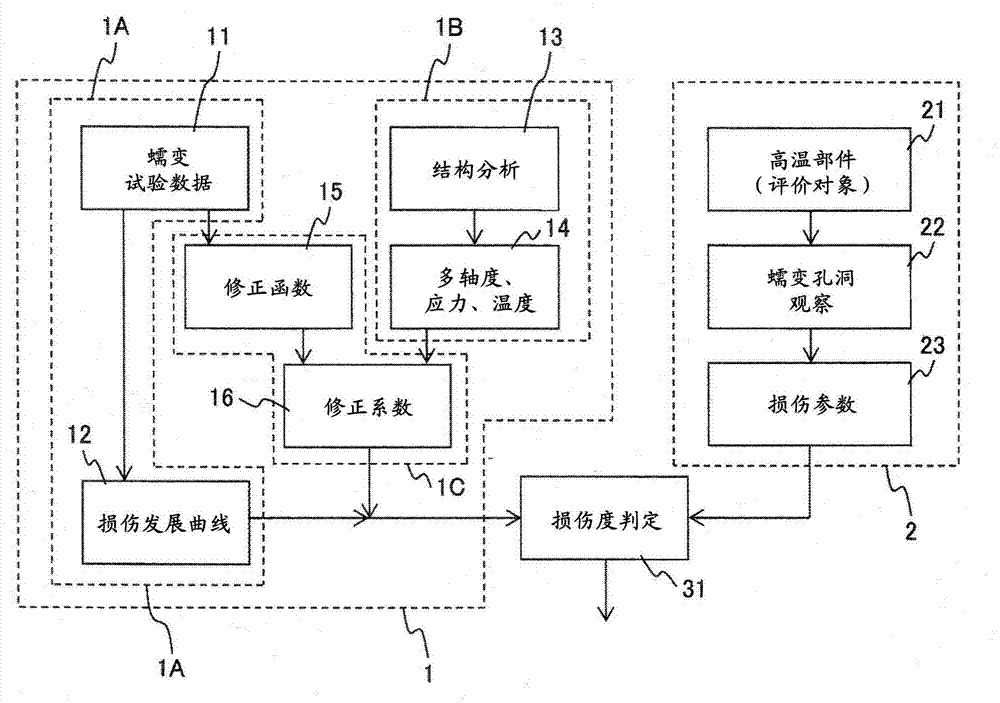

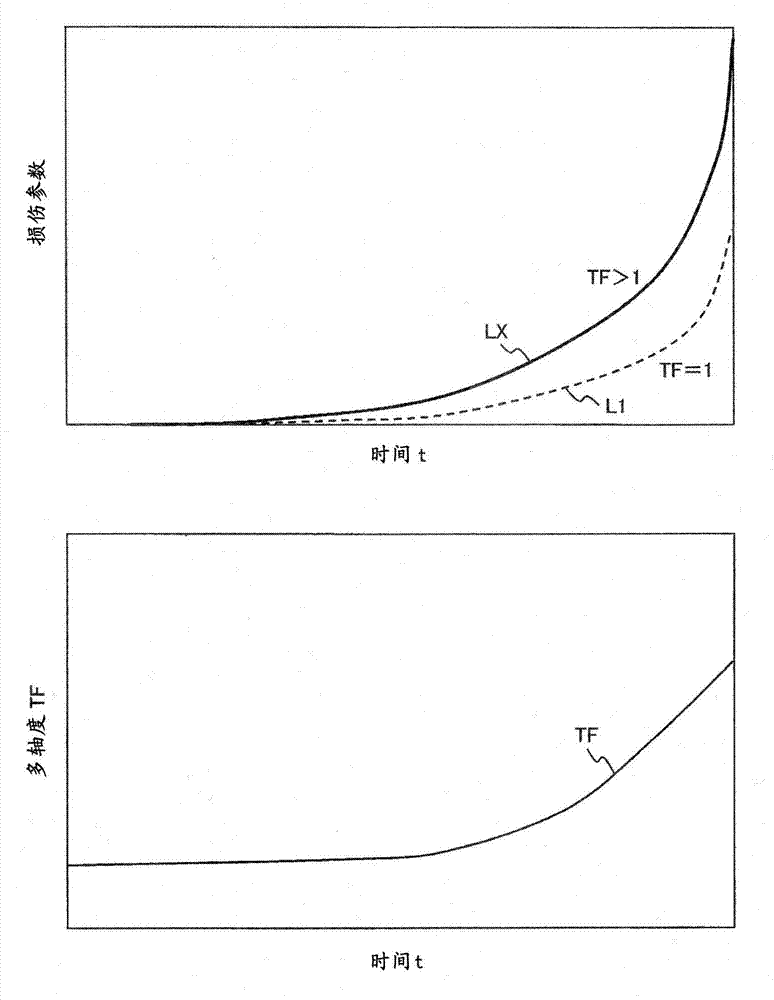

[0053] The present invention obtains damage parameters representing the degree of damage of high-temperature components applied to actual machines such as thermal power generation plants and has actual operating records, and evaluates and judges them. The judgment reference value at this time is determined by the multiaxiality damage growth curve obtained by correcting the damage growth curve under the uniaxial condition according to the multiaxiality.

[0054] Therefore, in the following description, the relationship between the multiaxiality and the damage development curve is first clarified, and then the specific correction method is explained. First, the multiaxiality will be described.

[0055] First, the multiaxiality TF is given by (1).

[0056] [mathematical formula 1]

[0057] TF = σ 1 + σ 1 + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com