Engine spray flow field near-field region optical diagnosis system

An optical diagnosis, engine technology, applied in fluid dynamics test, fluid velocity measurement, testing of machine/structural components, etc., to achieve the effect of improving the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

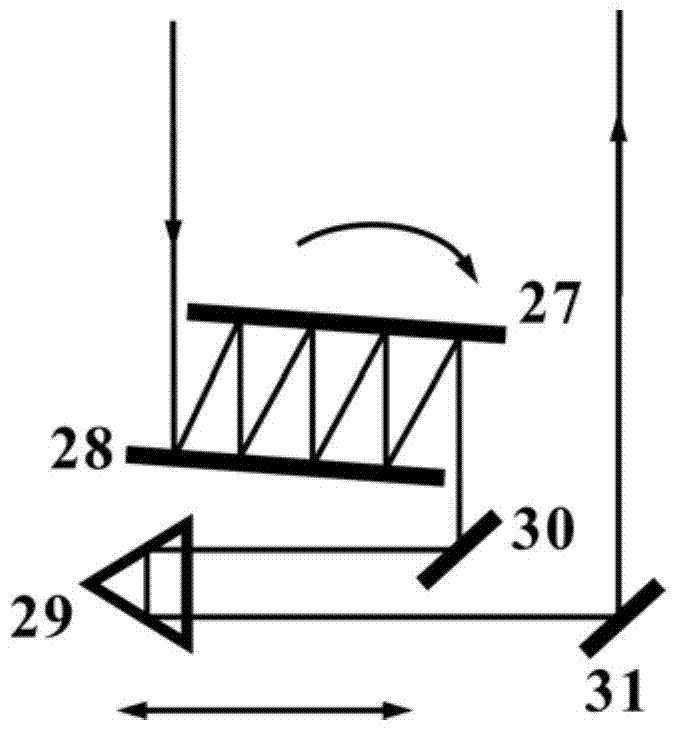

[0029] see Figure 1-2 , the ultra-high-speed flow field velocity and acceleration measurement system of the present invention includes a spectroscopic system, a multiplexing system, an optical Kerr gate strobe imaging system, and a comparative imaging system placed sequentially along the incident direction of the femtosecond pulsed laser; the spectroscopic system, multiplexing system of the present invention All optical components of the system, the optical Kerr gate gated imaging system and the comparative imaging system are mounted on an optical anti-vibration platform, and the planes of each component are perpendicular to the plane of the anti-vibration table.

[0030] The spectroscopic system is used to convert the femtosecond pulsed laser into a pulse train with nanosecond intervals consisting of frequency doubled light, horizontally polarized fundamental freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com