Intelligent pulping and grouting system

A pulping and intelligent technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of insufficient filling and compaction of grouting, large manual workload, incomplete exhaust, etc., and achieve precise control of pressure and complete exhaust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

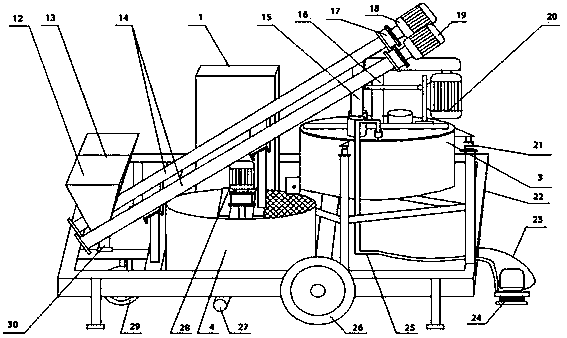

[0019] Such as figure 2 As shown, the present invention comprises: high-speed stirring pulping tank 3, low-speed stirring pulp storage tank 4, feeding system 2, automatic pulping machine 9, and is also provided with simultaneously:

[0020] (1) A weighing sensor 21 is provided, and the weighing sensor 21 is used for real-time monitoring of the weight of the high-speed stirring pulping tank 3, and transmits the monitoring data to the control center;

[0021] (2) A water inlet pipe 25, an auxiliary material feeding motor 18 and a main material feeding motor 19 are provided for sending water, auxiliary materials, and main materials into the high-speed stirring pulping tank 3;

[0022] (3) There is a control center 1, which is mainly used for: real-time monitoring of the weight of the high-speed mixing pulping tank, setting the weight of water, auxiliary materials, and main materials and comparing them with the monitored weight of the high-speed mixing pulping tank, and controlli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com