A kind of carbon fiber high-strength corrugated base paper and its preparation method

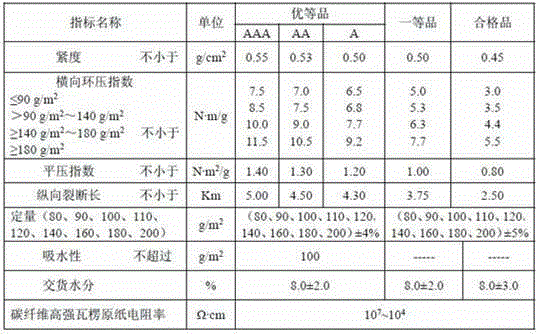

A technology for corrugated base paper and carbon fiber, applied in the field of papermaking, can solve the problems of low mechanical properties and anti-static performance, high cost of corrugated base paper, and achieve excellent anti-static effect, good tensile strength, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

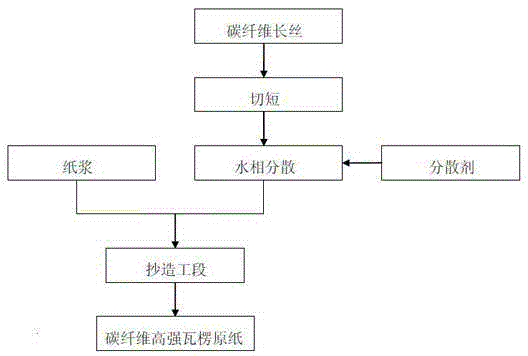

Method used

Image

Examples

Embodiment 1

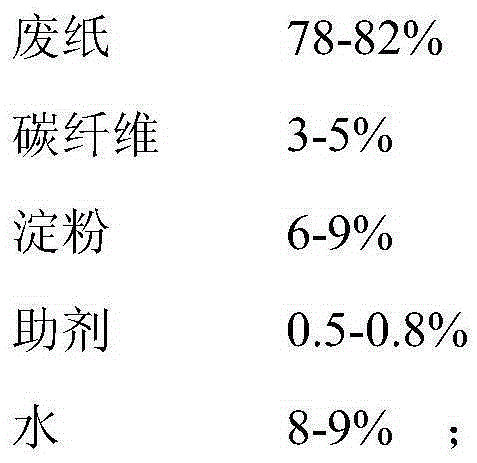

[0043] A carbon fiber high-strength corrugated base paper is made of the following raw materials in weight percentage:

[0044] Waste paper 80%, carbon fiber 4%, starch 7.4%, additives 0.6%, water 8%;

[0045] Wherein, auxiliary agent is rosin, alum, oxidized starch, soda ash, dispersant, non-ionic polymer flocculant, surface sizing agent, bactericide, defoamer, retention aid, and the weight ratio of above is (40 -120):(100-350):(100-350):(5-12):(1-4):(0.2-1):(0.2-1):(0.2-1):(0.2-1 ):(0.2-1):(0.2-1).

[0046] The waste paper is AOCC waste paper and LOCC waste paper, and the weight ratio of the two is 3:2. The dispersant is one or both of polyvinyl alcohol and polyacrylamide.

[0047] The preparation method of carbon fiber high-strength corrugated base paper comprises the following steps:

[0048] S1: Weigh raw materials

[0049] Take raw material according to above-mentioned parts by weight;

[0050] S2: carbon fiber treatment

[0051] Shorten or grind the carbon fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com