Waste copper sulfate electrolyte purification system and method

A technology for waste electrolyte and purification system, which is applied to the purification system of copper sulfate waste electrolyte and the purification field of copper sulfate waste electrolyte, which can solve the problem of decreased heat exchange efficiency of heat exchangers, scaling of plate heat exchangers, water-containing and acid-containing solutions It can ensure the safety of equipment, reduce water and acid content, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

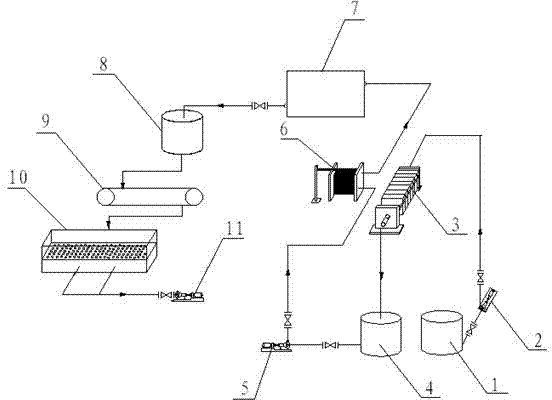

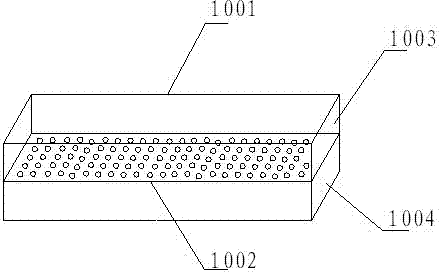

[0015] Such as figure 1 As shown, a copper sulfate waste electrolyte purification system includes a waste electrolyte storage tank 1, a waste electrolyte pump 2, a plate filter 3, a filter waste liquid storage tank 4, a filter waste liquid pump 5, and a plate filter connected in sequence. Heater 6, vacuum evaporator group 7, copper sulfate water-cooled crystallization tank 8, belt filter 9 and suction filter tank 10; There is an orifice plate 1002, which divides the tank body into a material chamber 1003 and a suction filter chamber 1004 arranged in an upper and lower position. The filter cloth (not shown in the figure) is laid on the orifice plate 1002, and the suction filter chamber 1004 is connected to a vacuum pump. 11. Vacuum pump 11 is preferably a water ring vacuum pump.

[0016] A method for purifying copper sulfate waste electrolyte by using the above system, the specific steps are: pump the waste electrolyte stored in the waste electrolyte storage tank 1 into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com