A kind of novel cationic polymer leather fatliquoring agent and preparation method thereof

A technology of cationic polymer and leather fatliquoring agent, which is applied in leather impregnation, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., which can solve the problem of low dyeing rate , poor absorbency and other problems, to achieve the effect of increasing the absorption rate, reducing the content, and improving the hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

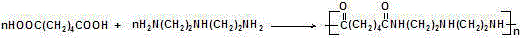

Method used

Image

Examples

Embodiment 1

[0032] (1) 103.7g of diethylenetriamine and 0.7g of p-toluenesulfonic acid are loaded into a reactor with a water separator, 146.14g of adipic acid are added, stirred evenly, and N 2 , the temperature was raised to 160°C, and the reaction was held for 120 minutes. A bright yellow viscous liquid polydiethylenetriamine adipate (intermediate I) was obtained.

[0033] (2) Cool down the temperature of the product obtained in step 1 to 80°C, add 65g of 1-bromohexadecane into the reactor, and react at 80°C for 120min to obtain intermediate II.

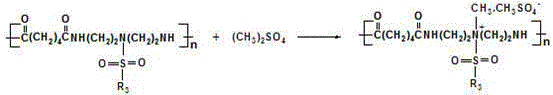

[0034] (3) Cool the intermediate II obtained in step 2 to 30°C, take 100 g of acetone, and add it to the reaction kettle at one time under strong stirring. After stirring for 30 minutes, add 30 g of dimethyl sulfate and react at 50° C. for 180 minutes. After the reaction was completed, the solvent was removed under reduced pressure, the vacuum degree was 10 mmHg, and the temperature was lowered to below 40°C. Add deionized water to adjust ...

Embodiment 2

[0036] (1) 146.24g triethylenetetramine, 2.0g p-toluenesulfonic acid are packed into the reactor with water separator, 146.14g adipic acid, stir evenly, pass into N 2 , the temperature was raised to 150°C, and the reaction was held for 180 minutes. A bright yellow viscous liquid polyamide resin (intermediate I) was obtained.

[0037] (2) Cool down the temperature of the product obtained in step 1 to 70°C, add 380g of 1-bromohexadecane into the reaction kettle, and react at 70°C for 150min to obtain intermediate II.

[0038] (3) Cool the intermediate II obtained in step 2 to 30° C., take 130 g of butanone, and add it to the reactor at one time under strong stirring. After stirring for 60 minutes, 190 g of dimethyl sulfate was added and reacted at 70° C. for 300 minutes. After the reaction was completed, the solvent was removed under reduced pressure, the vacuum degree was 15 mmHg, and the temperature was lowered to below 40°C. Add deionized water to adjust the solid content of...

Embodiment 3

[0040] (1) 103.7g of diethylenetriamine and 1.0g of p-toluenesulfonic acid are loaded into a reactor with a water separator, 146.14g of adipic acid are added, stirred evenly, and N 2 , heated up to 150°C. Insulation reaction 150min. A bright yellow viscous liquid polyamide resin (intermediate I) was obtained.

[0041] (2) Lower the temperature of intermediate I obtained in step 1 to 80°C, take 155g of pentadecylsulfonyl chloride into the reaction kettle, and react at 80°C for 150min to obtain intermediate II.

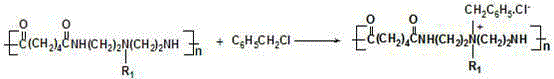

[0042] (3) Lower the temperature of intermediate II obtained in step 2 to 30°C, and add 150 g of isopropanol into the reactor at one time under vigorous stirring. After stirring for 45 minutes, 185 g of benzyl chloride was added and reacted at 70° C. for 200 minutes. After the reaction was completed, the solvent was removed under reduced pressure, the vacuum degree was 20mmHg, and the temperature was lowered to below 40°C. Add deionized water to adjust the solid con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com