Silica gel for electronic components and preparation method thereof

A technology of electronic components and silicone gel, applied in the direction of adhesives, etc., can solve the problem of failure to solve the problem of silicone gel adhesion, toughness and strength, the inability to guarantee the toughness and strength of silicone gel, and the inability to guarantee the adhesion of electronic components Sex and other issues, to achieve the effect of increasing toughness, good adhesion, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

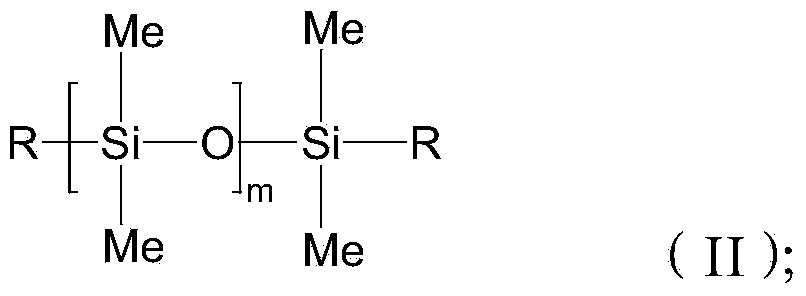

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the B component is:

[0034] According to [(Si-H) / (CH 2 =CH-Si)] mixed at a molar ratio of 0.2 to 0.6, then crosslinked under the action of a platinum catalyst, and distilled under reduced pressure at 180 to 200°C for 2 to 4 hours to obtain an intermediate;

[0035] Mixing the intermediate with side hydrogen-containing silicone oil and inhibitor to obtain component B;

[0036] The mass of the catalyst is 2-4‰ of the total mass of the A component and the B component;

[0037] The mass of the inhibitor is 2-3‰ of the total mass of components A and B;

[0038] The number of moles of Si-H bonds in terminal hydrogen-containing silicone oil and side hydrogen-containing silicone oil is related to [CH in terminal vinyl silicone oil and side vinyl silicone oil. 2 =CH-Si] bond molar ratio is less than 1.

[0039] In the present invention, the silica gel includes component A and component B, and the mass ratio of component A to component B is 1:1. Wh...

Embodiment 1

[0075] Preparation of component A: Accurately weigh 100 g of side vinyl silicone oil with a viscosity of 1000 mPa·s and 0.5 g of Pt-vinyl siloxane chelate with a concentration of 5000 ppm, mix them and stir evenly.

[0076]Preparation of component B: Accurately weigh 60g of vinyl-terminated silicone oil with a viscosity of 1500mPa s and 15g of 0.08% hydrogen-terminated silicone oil and mix them. (CH 2 =CH-Si)] in a molar ratio of 0.2:1; then lightly cross-linked under the action of a platinum catalyst, distilled under reduced pressure at 200°C for 2 hours, and finally added 25g of side hydrogen-containing silicone oil with a hydrogen content of 1.3%, methyl Butynol 0.5g. The number of moles of Si-H bonds in terminal hydrogen-containing silicone oil and side hydrogen-containing silicone oil and the CH in terminal vinyl silicone oil and side vinyl silicone oil 2 The molar ratio of =CH-Si bond is 0.4:1.

[0077] When in use, mix the prepared component A and component B uniform...

Embodiment 2

[0079] Preparation of component A: Accurately weigh 100 g of side vinyl silicone oil with a viscosity of 1000 mPa·s and 0.5 g of Pt-vinyl siloxane chelate with a concentration of 5000 ppm, mix them and stir evenly.

[0080] Preparation of component B: Accurately weigh 60g of vinyl-terminated silicone oil with a viscosity of 500mPa·s and 15g of 0.08% hydrogen-terminated silicone oil and mix them. CH 2 =CH-Si)] in a molar ratio of 0.6:1; then lightly crosslinked under the action of a platinum catalyst, distilled under reduced pressure at 200°C for 2 hours, and finally added 25g of side hydrogen-containing silicone oil with a hydrogen content of 0.9% and methyl Butynol 0.5g, mix and stir evenly.

[0081] The number of moles of Si-H bonds in terminal hydrogen-containing silicone oil and side hydrogen-containing silicone oil and the CH in terminal vinyl silicone oil and side vinyl silicone oil 2 The molar ratio of =CH-Si bond is 0.8:1.

[0082] When in use, mix the prepared comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com