Water meter shell material and preparation method thereof

A casing material and water meter technology, applied in the field of water meter casing materials and its preparation, can solve the problems of excessive waste of materials, increased production costs, insufficient application, etc., and achieve the effects of convenient transportation, extended service life, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

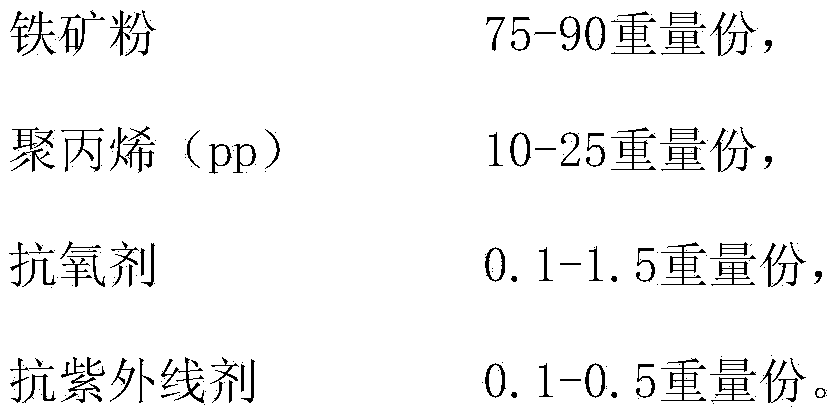

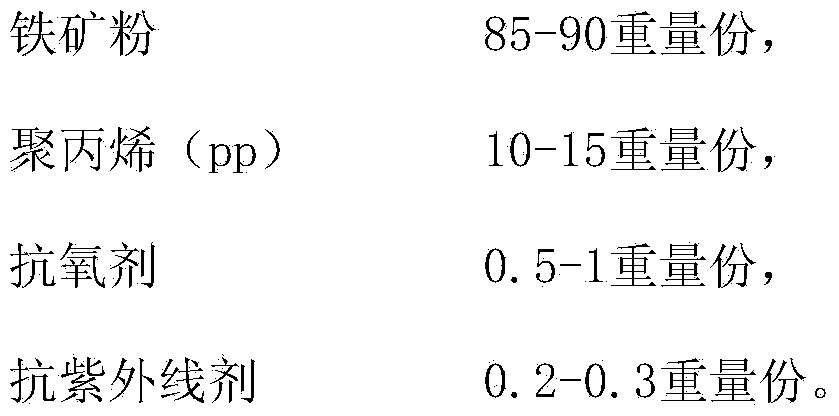

Method used

Image

Examples

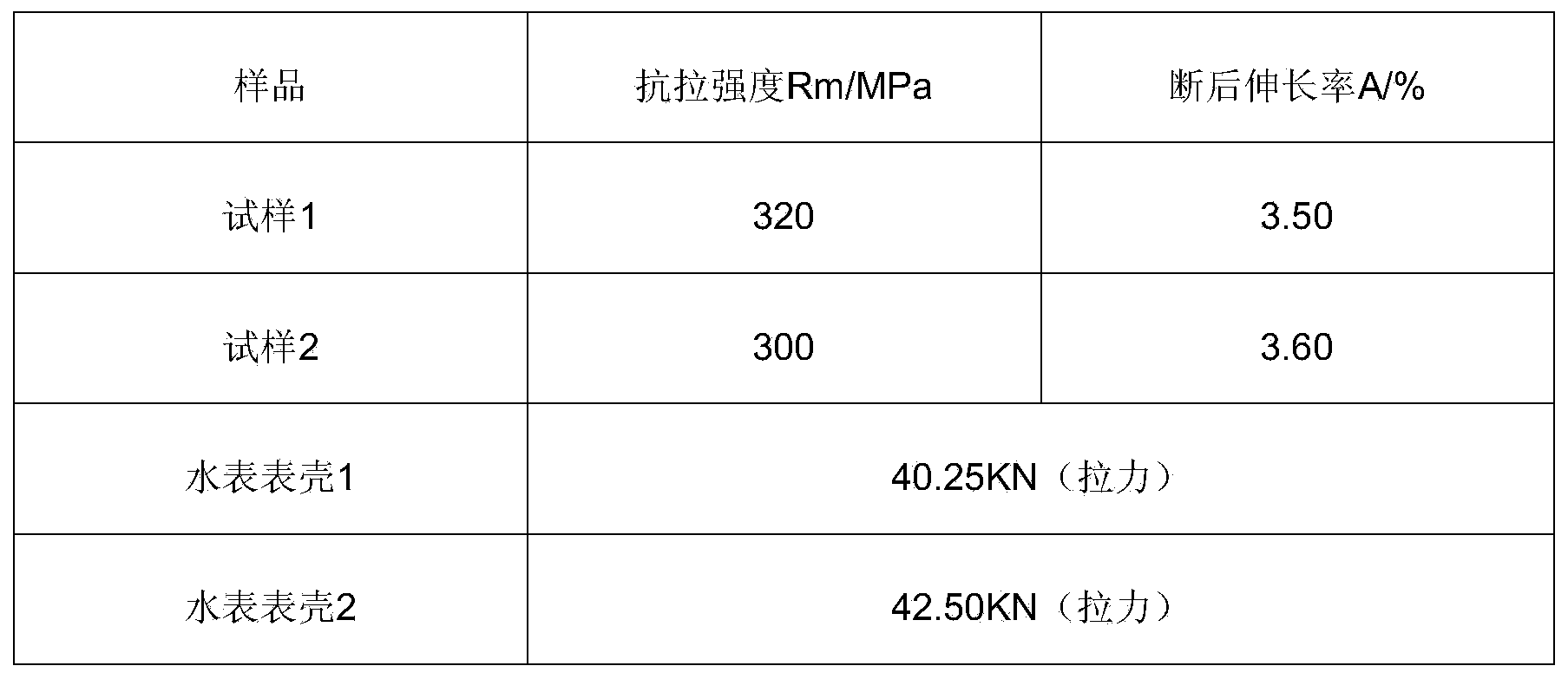

Embodiment 1

[0023] Water meter shell material, the material preparation raw materials include: 90 parts by weight of iron ore powder, 8.5 parts by weight of polypropylene (pp),

[0024] 1 part by weight of antioxidant, 0.5 part by weight of anti-ultraviolet agent. The antioxidant is a 1:1 mixture of antioxidant 1010 and antioxidant 168. The anti-ultraviolet agent is UV-531.

[0025] Preparation steps include:

[0026] (1) First, dry the polypropylene raw material at 50°C for 2 hours to remove moisture and other impurities that affect product quality;

[0027] (2) Add the polypropylene raw material dried in step (1) into the injection screw of the injection molding machine, then add antioxidant and anti-ultraviolet agent, and heat and melt at 200°C;

[0028] (3) adding iron ore powder to the raw material in the molten state in the injection molding screw in step (2) to obtain a mixture;

[0029] (4) Inject the mixed material in step (3) into the mold with a temperature of 60°C through ...

Embodiment 2

[0031] Water meter shell material, the material preparation raw materials include: 85 parts by weight of iron ore powder, 14 parts by weight of polypropylene (pp),

[0032] 0.5 parts by weight of antioxidant, and 0.5 parts by weight of anti-ultraviolet agent. Antioxidant is Antioxidant 1010. The anti-ultraviolet agent is UV-531.

[0033] Preparation steps include:

[0034] (1) First, dry the polypropylene raw material at 50°C for 2 hours to remove moisture and other impurities that affect product quality;

[0035] (2) Add the polypropylene raw material dried in step (1) into the injection screw of the injection molding machine, then add antioxidant and anti-ultraviolet agent, and heat and melt at 200°C;

[0036] (3) adding iron ore powder to the raw material in the molten state in the injection molding screw in step (2) to obtain a mixture;

[0037] (4) Inject the mixed material in step (3) into the mold with a temperature of 60°C through the screw extrusion of the injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com