Casting machine used for casting special materials

A special material, casting machine technology, applied in foundry, foundry equipment, pig iron foundry and other directions, can solve problems such as reducing yield and affecting service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

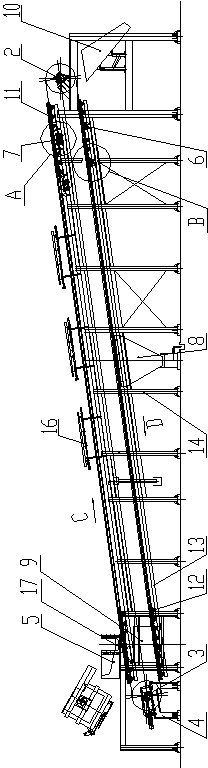

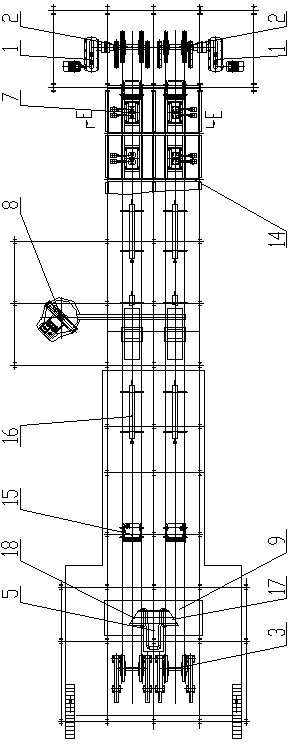

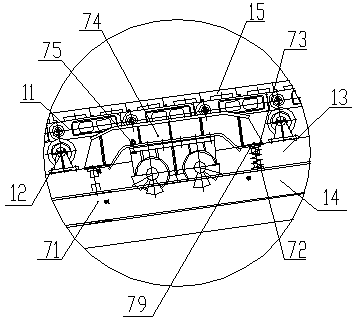

Image

Examples

Embodiment 1

[0049] The material of the casting mold is to add 1.00% chromium (Cr) and 0.30% molybdenum (Mo) of the total mass to ZG270-500 cast steel to form a low-alloy steel of ZG35CrMo material, which improves the high temperature performance of the casting mold and improves its creep resistance ability to change. The mass percentages of raw materials in ZG270-500 cast steel are as follows: C 0.30~0.37%, Si 0.20~0.90%, Mn 0.50~1.00%, P≤0.030%, S≤0.030%, and the rest is iron. The structure of the casting mold is simulated and analyzed by the temperature field. The wall thickness is 45mm. The top dimension of the mold cavity is designed to be a×b, and the bottom is spherical. The actual embodiment is to design the size of the molding cavity according to the size of the alloy material forming block "top width x bottom diameter x height = 80 x SR26 x 55mm, the sky is square and the earth is round", the bottom diameter SR is a hemispherical structure of 25mm, and the longitudinal outer wall...

Embodiment 2

[0051] The material of the casting mold is to add 1.75% nickel (Ni), 1.00% chromium (Cr) and 0.30% molybdenum (Mo) to ZG230-450 to form ZG25NiCrMo low-alloy steel to improve casting fluidity. Improve the strength of steel and improve its toughness; improve the high temperature performance of the casting mold and improve its creep resistance. The mass percentages of raw materials in ZG230-450 cast steel are as follows: C 0.22~0.30%, Si 0.20~0.90%, Mn 0.50~1.00%, P≤0.030%, S≤0.030%, and the rest is iron.

[0052] The structure of the casting mold is simulated and analyzed by the temperature field. The wall thickness is 55mm. The top dimension of the mold cavity is designed to be a×b, and the bottom is spherical. The actual embodiment is designed for the size of the forming block of non-metallic material "top width x bottom diameter x height = 80 x SR28 x 55mm, the sky is square and the earth is round". The size of the molding cavity is designed. The radius of the arc R is 55. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com