Method for cleaning internal surface of copper coil

An inner surface, copper coil technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., to achieve the effects of convenient acquisition, low cost, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

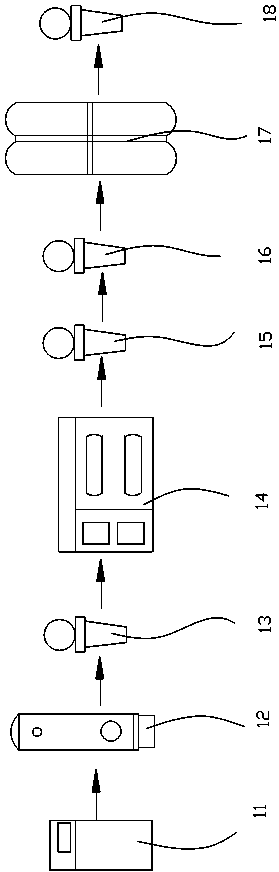

[0032] Coil such as figure 1 and figure 2 shown.

[0033] For coils with an outer diameter of 7.94mm, a wall thickness of 0.28mm, a coil weight of 150kg, a length of 2500m, and a cleanliness requirement of less than 10 mg / m2,

[0034] Step a, inject 100-200ml of cleaning agent 4 from the inlet end 1 of the coil, and then insert 3-5 sponge balls 3, the diameter of which is 0.3-0.5mm larger than the inner diameter of the coil;

[0035] Step b, inject 300-400ml of cleaning agent 4 into the same inlet port 1 of the coil, and then plug 3-5 sponge balls 3, the diameter of which is 0.3-0.5mm larger than the inner diameter of the coil;

[0036] Step c, blowing compressed purified air into the inlet port that has been processed in step b above, with a pressure of 3-6Mpa and a flow rate of 10-11M 3 / min, push the sponge ball to clean the inner surface of the copper pipe until all the sponge ball is blown out from the outlet end 2 of the coil;

[0037] Step d, the color of the last ...

Embodiment 2

[0042] First, clean the coil with an outer diameter of 6.35mm, a wall thickness of 0.7mm, a coil weight of 500kg, a length of 4375m, and a cleanliness requirement of less than 10mg / m2. The steps are as follows:

[0043] Step a, first inject 100-200ml of cleaning agent 4 into the inlet end 1 of the coil, and then insert 3-5 sponge balls 3, the diameter of which is 0.3-0.5mm larger than the inner diameter of the coil;

[0044] Step b, inject 800-1000ml of cleaning agent 4 into the same inlet port 1 of the coil, and then add 3-5 sponge balls 3, the diameter of which is 0.3-0.5mm larger than the inner diameter of the coil;

[0045] Step c, blowing compressed purified air into the inlet port that has been processed in step b above, the air pressure is 3-6Mpa, and the flow rate is 10-11M 3 / min, push the sponge ball to clean the inner surface of the copper pipe until all the sponge ball is blown out from the outlet end 2 of the coil;

[0046] Step d, the color of the last sponge ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com