Squeegee tool

A tool and squeegee technology, which is applied in the field of photovoltaic silicon ingot bonding, can solve the problems of affecting the effect of exhaust gas and bonding effect, and achieve the effect of avoiding initial curing, removing air bubbles and improving the effect of diversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below by specific examples.

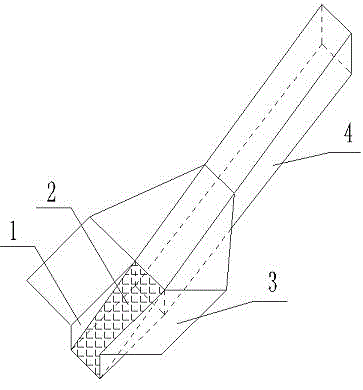

[0008] As shown in the figure, the squeegee tool of the present invention includes a U-shaped groove 1, a wing plate 3 and a deflector 2. The wing plate is connected to the two side plates of the U-shaped groove and is inclined to the outside of the U-shaped groove. The deflector and the bottom plate of the U-shaped groove form an acute angle.

[0009] The height of the U-shaped groove of the squeegee tool is higher than the height of the glass diversion groove, the width of the U-shaped groove is smaller than the width of the glass diversion groove, the deflector of the squeegee tool, and the distance between the deflector and the U-shaped groove The acute angle between the bottom plates is 15°~30°, which can effectively introduce the resin glue. The squeegee tool includes a handle 4, which is connected to the U-shaped groove and forms an integral body with the two wing plates, which is conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com