Mica tape production method without using organic solvent

An organic solvent, mica tape technology, applied in mica, inorganic insulators, insulators, etc., can solve the problems of difficult control of coating position and uniformity, potential safety hazards due to high voltage charges, and high production cost of mica tapes, and achieve uniformity of gluing. Ease of control, reduced energy consumption, less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

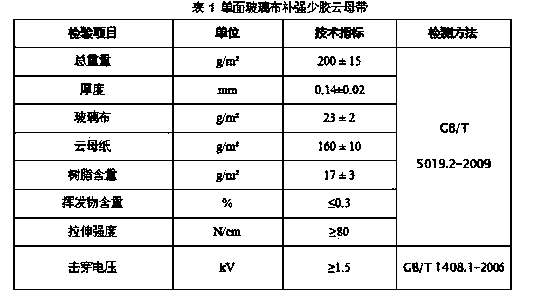

[0038] Example 1: Single-sided glass cloth reinforced mica tape with less glue

[0039] Using the solvent-free mica tape production method to prepare single-sided glass cloth reinforced mica tape with less glue, the required raw materials are as follows:

[0040] 1) Polyester modified epoxy resin, 1%-10% filler is added to the resin, and the softening point of the resin is (45±2) °C.

[0041] 2) Muscovite paper quantification is (160±10) g / m 2 , The mica paper contains 3-7% polyaramid fibers.

[0042] 3) The mass per unit area is 20-26g / m 2 High-quality glass fiber cloth, the warp and weft densities are 23-27 threads / cm and 9-13 threads / cm respectively, and the glass cloth is treated with a coupling agent compatible with epoxy.

[0043] Such as figure 1 As shown, the specific process of preparing single-sided glass cloth reinforced mica tape with less glue by adopting the production method of mica tape without using organic solvent is as follows:

[0044] A. After the...

Embodiment 2

[0049] Embodiment 2: Single-sided polyester film reinforced less glue mica tape

[0050] Adopting the production method of mica tape without using organic solvents to prepare single-sided polyester film reinforced mica tape with little glue, the required raw materials are as follows:

[0051] 1) Modified polyester resin, resin softening point (40±2) ℃.

[0052] 2) Muscovite paper quantification is (160±10) g / m 2 .

[0053] 3) The mass per unit area is 42g / m 2 Polyester film, polyester film thickness 0.03mm.

[0054] Such as figure 2 Shown, take the mica tape production method that does not use organic solvent to prepare the concrete technological process of single-sided polyester film reinforcement little glue mica tape as follows:

[0055] A. After the mica paper is unrolled, it is coated with adhesive by the heating roller, the temperature of the roller is (95±3)℃, and the amount of glue applied is (10-15)g / m 2 .

[0056] B. Composite the polyester film with the mi...

Embodiment 3

[0062] Example 3: Porous mica tape

[0063] Adopt not to use organic solvent mica tape production method to prepare porous mica tape, required raw material is as follows:

[0064] 1) Polyester modified epoxy resin, resin softening point≦45℃.

[0065] 2) Muscovite paper quantification is (160±10) g / m 2 , The mica paper contains 3-7% polyaramid fiber.

[0066] 3) The mass per unit area is 20-26g / m 2 High-quality glass fiber cloth, the warp and weft densities are 23-27 threads / cm and 9-13 threads / cm respectively, and the glass cloth is treated with a coupling agent compatible with epoxy.

[0067] 4) The mass per unit area is (20±3) g / m 2 polyester non-woven fabric.

[0068] Such as image 3 Shown, take the mica tape production method that does not use organic solvent to prepare the concrete technological process of porous mica tape as follows:

[0069] A. After the mica paper is unrolled, it is coated with adhesive by the heating roller, the temperature of the roller is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com