Multi-angle and multi-point measuring device and method of laser gain medium cladding residual reflection

A technology of residual reflection and laser gain, which is used in measurement devices, measurement of scattering properties, material analysis by optical means, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

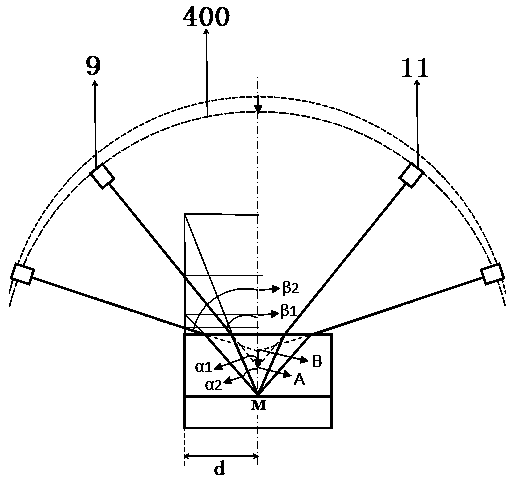

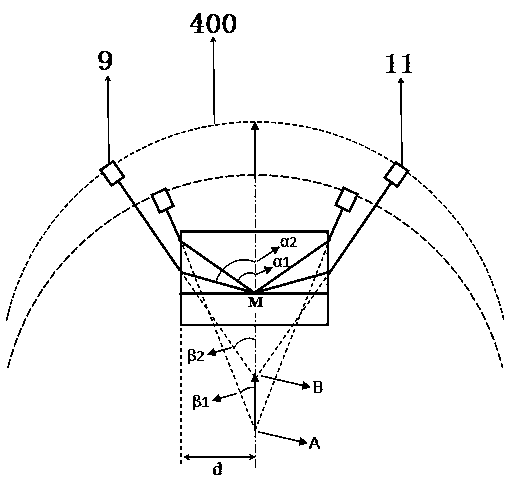

[0039] In the following, the present invention will be described in detail by taking the residual reflection measurement of the neodymium glass envelope boundary surface as a specific example in conjunction with the accompanying drawings, but this should not limit the protection scope of the present invention.

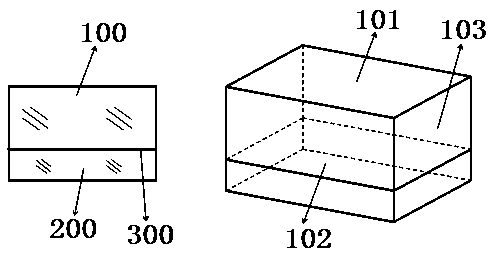

[0040] Such as Image 6As shown, a multi-angle and multi-point measurement device for the residual reflection of the laser gain medium wrapper, including a measurement laser 1, a power adjustment device 2, a first high reflection mirror 3, a beam shaping device 4, a beam splitter 5, and a laser intensity detector 6. Optical fiber coupler 7, optical fiber 8, laser transmitter 9, laser glass sample 10, residual reflection detector 11, laser transmitter movement mechanism 12, residual reflection detector movement mechanism 13, precise positioning movement mechanism 14, indicating laser 15 , an optical switch 16, a second high reflection mirror 17, and a partial reflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com