Load system of hydrostatic transmission device detecting platform

A technology of transmission device and detection platform, applied in the direction of fluid pressure actuation device, fluid pressure actuation system safety, fluid pressure actuation system components, etc., can solve the problem of high manufacturing cost, high energy consumption, and reduced valve stem sealing performance. problem, to achieve the effect of less influencing factors, lower pollution level, and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

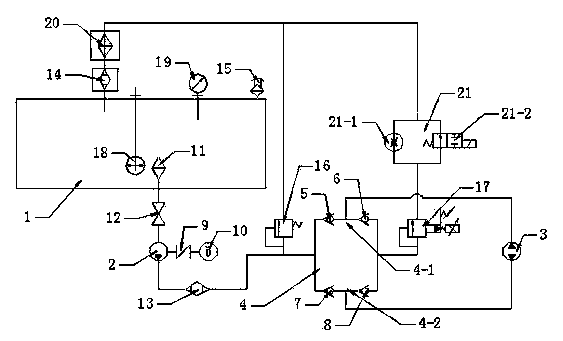

[0018] The load system of the detection platform of the hydrostatic transmission device of the present invention is mainly composed of the following components: a fuel tank 1 , a one-way hydraulic pump 2 , a loading pump 3 , and an oil supply circuit 4 for the loading pump.

[0019] As shown in the figure, the oil supply circuit 4 of the loading pump is composed of the circuit A4-1 and the circuit B4-2 in parallel. The circuit A4-1 is composed of the check valve a5 and the check valve b6 in series. The two check valves The installation direction is the same. The circuit B4-2 is composed of the one-way valve c7 and the one-way valve d8 in series. The installation directions of the two one-way valves are the same. The oil ports are connected, and the oil outlets are connected.

[0020] Fuel tank 1, one-way hydraulic pump 2, and loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com